QMTLubControl

Automatic watchmaking lubrication control

Control station

of the lubrication process for SVM equipment

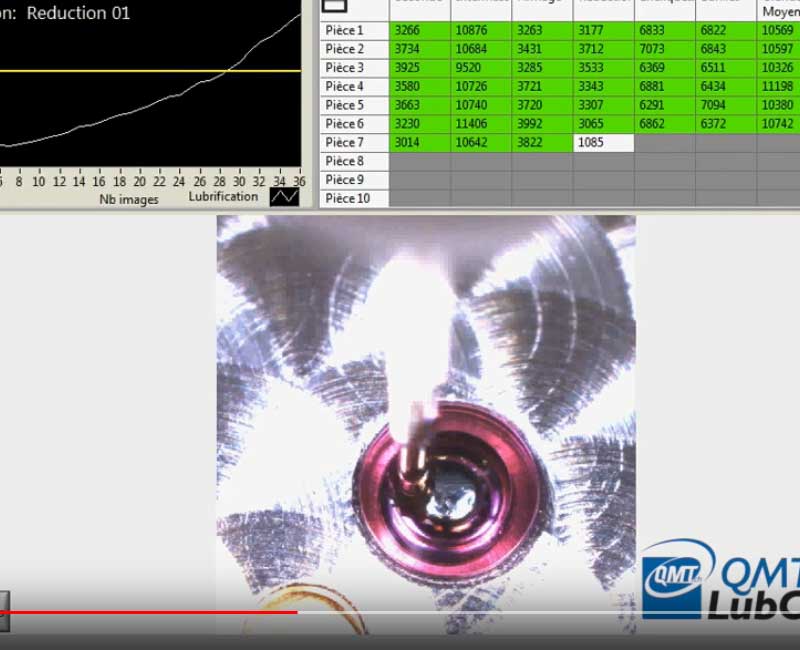

QMTLubControl is a vision station for high resolution visualization and control of the lubrication process of SVM equipment. The recording of the lubricating film to improve the control of the process as well as the automatic control by image processing of the good progress of the process are offered as options. These options allow an improvement of the control in order to guarantee the good lubrication of the movements.

- High resolution, high speed viewing

- The possibility of reviewing the film of a lubrication already carried out (option)

- Automatic process control by image processing (option)

Automated lubrication control

QMTLubControl-Expert allows automated control of the lubrication of watch components

readingCustomizable solutions to perfectly meet your needs

QMTLubControl technologies

The heart of the equipment is a digital image acquisition system

qmt has developed an algorithm specifically for this application in order to be able to automatically characterize the lubrication and thus detect parts with defects

Color cameras with a resolution of 1'300 x 1'000 pixels and an acquisition speed of 84 images / second

A custom electronic module allows multiplexing of cameras and lighting (up to 8x).

A computer is integrated to relays the acquisition of the images, the display and the processing

QMTLubControl applications

QMTLubControl is suitable for the SVM Triax robot both in its stand-alone version and in its version integrated into an automatic line

QMTLubControl is suitable for the SVM Incalub for impact control

QMTLubControl software options

Basic version of the software that allows continuous display of the process in color and at high resolution

This version allows, in addition to the basic functions, the automatic recording of the film of all the lubrication points. It is thus possible to visualize the process after the fact to verify its good progress.

This option allows automatic control of the lubrication process. An algorithm specifically developed by Qualimatest allows robust control even with the variable aspect of the stones

Fit for you program (FFY)

Qualimatest products can be customized both in terms of equipment and software. The first level of software customization is the addition of additional functions (available under QMTStore) or the development of a custom function.

On the basis of Qualimatest products, it is proposed to produce a labeled product on behalf of our customers who may be private or marketed by themselves.

More than 1000 systems have been delivered to a wide customer base since 1989

Customer SuccessWatchmaking lubrication control

| Functions | QMTLubControl-Base | QMTLubControl-Pro | QMTLubControl-Expert |

|---|---|---|---|

| Optical system | 1'280 x 1'024 pixels and 75 images / sec, FOV 4.3 x 3.3mm | ||

| Of stations | 1 to 8 cameras | 1 to 8 cameras | 1 to 8 cameras |

| Lighting control | Power supply and lighting control (maximum 8) | ||

| Visualization and display | Continuous process display on 17 “screen | ||

| Communication with machine | Communication and synchronization between the control system and the machine | ||

| Save and later view | - | Automatic process saving. Possibility to view previous oilings | |

| Automatic control | - | - | Automatic check for correct operation during the process |

| Hardware | Compact computer system integrated into the machine | High power computer system | |

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control