Solutions for dimensional control

Very high precision measurements and aesthetic control

Dimensional control

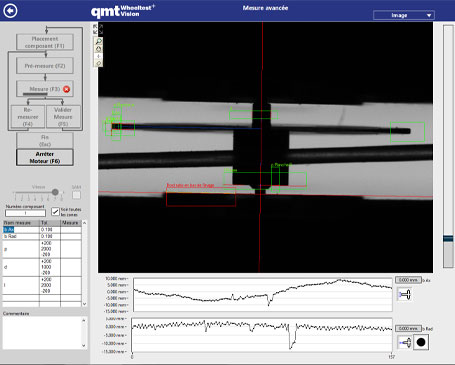

Quality control in production is necessary to monitor the manufacturing process in order to make the necessary corrections and thus ensure that the manufactured parts meet the requirements. In the specific field of microtechnology, tolerances can be very tight, requiring special attention to measurement. Historically, these were carried out using contact measuring benches; these are now often replaced by optical devices.

Automated optical inspection ensures the quality of manufactured parts while optimizing manufacturing costs. This inspection can be carried out by sampling with a testing device such as the qmtprojector-100 or 100% with a testing station integrated into an automatic process.

Customizable solutions to perfectly meet your needs

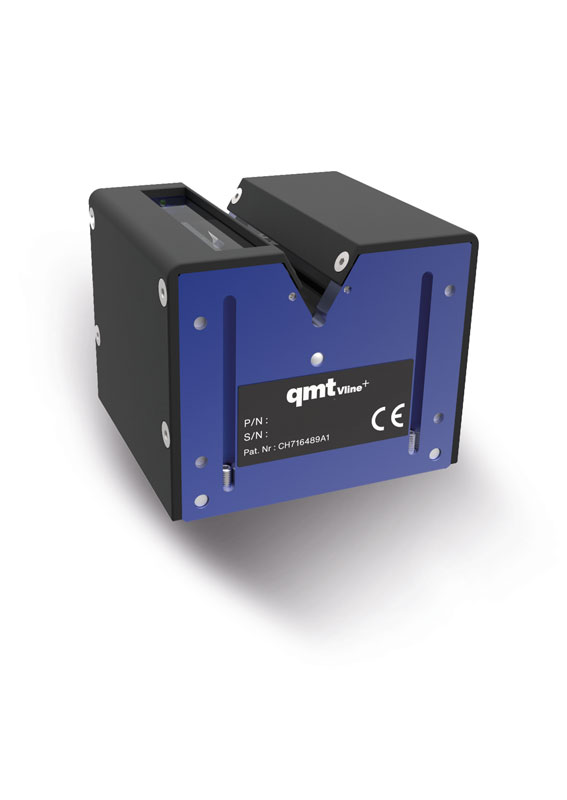

Standard products for dimensional control

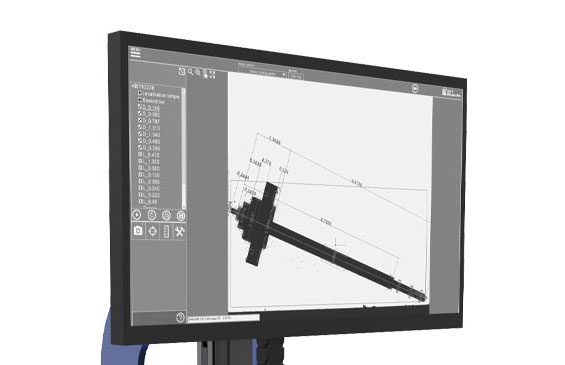

Dimensional measurements

open fields

Beat measurements

and shares

Pose for measurement

of turned parts

Sorting machine

for axes

Full-field optical measurement

The importance of installation for turned parts

Dynamic measurement for beat measurement