The customer product program (qmtoem)

Products developed for industrialization on behalf of our customers

Your equipment developed and managed as a product by qmt

The qmtoem program corresponds to the specific needs of our customers or requests for customization of our products. These needs are initially addressed within the framework of tailor-made development (qmtm4u program).

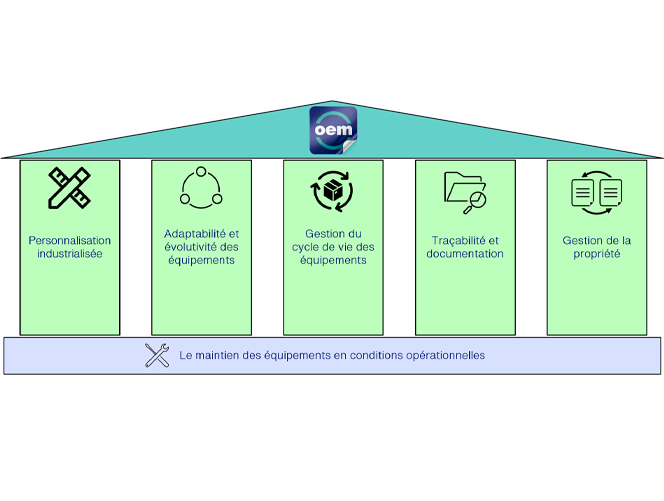

The qmtoem program makes it possible to industrialize and maintain these developments over time. This means that the entire product life cycle is covered. The products of the qmtoem program are dedicated, which allows them to evolve over time according to the needs and constraints of a single customer.

- Management of obsolescence of components, software and operating systems with upgrade and product update campaigns

- Monitoring and processing changes over time according to a rigorous change control process

- Strong maintenance commitments in operational condition

These products can thus be marketed by our customers in their names or used privately.

Customizable solutions to perfectly meet your needs

This program is intended for customers who have equipment needs that do not exist on the market with deployment potential (internal or external). These products can thus be marketed by our customers in their names or used privately.

The objectives are:

- Adding testing or quality control features to a machine

- Manage test and control resources like products to secure and control their activities

- Meet specific equipment needs with deployment potential (small and medium series)

- Harmonize and homogenize the test and control solutions used

- Guarantee the capacity for evolution over time of test and control solutions

The qmtoem program allows the transition from a tailor-made solution (qmtm4u program) to an industrialized product. It is thus possible to combine the advantages of a solution perfectly suited to your needs and of a product.

qmt guarantees the possibility of evolving qmtoem products thanks to an evolution process which integrates the evaluation of the impacts on the product and its documentation. The modular platform used also allows the creation of plugin functionality in order to be able to customize functions without modifying the main software.

Qmtoem product lifecycle management is offered by qmt to guarantee future deployments as well as maintenance in operational conditions (MCO)

- Monitoring component obsoleteness

- Monitoring of non-conformities and request for improvements

- Process for monitoring changes and developments

qmt guarantees the maintenance of qmtoem product documentation as well as provision with collaborative tools. It is therefore available at all times for qmt employees and for the customer with the guarantee of updating.

qmt discusses with the customer the ownership of the products developed in order to define the optimal solution for both parties.

The LPM TPM is a product intended for measuring rail geometry. It is marketed by the company Speno International SA.

More than 35 years of history

A history marked by innovation. qmt developed the Multimicro in 1991, which received an award from Crédit Suisse (motorized image analyzer with automatic microhardness measurement). In 2015, qmt won the Geneva Canton Innovation Award.

Our historyqmtoem customer product example

QMT know-how for the implementation of solutions

Development of intuitive and high-performance industrial software including Artificial Intelligence

Multi-physical measurements (torque, force, speed, position, etc.)

Intelligent Data Management and Artificial Intelligence