Solutions for aesthetic control

Simplicity of implementation thanks to a standard approach and classification with Artificial Intelligence

Automate the aesthetic control of your products

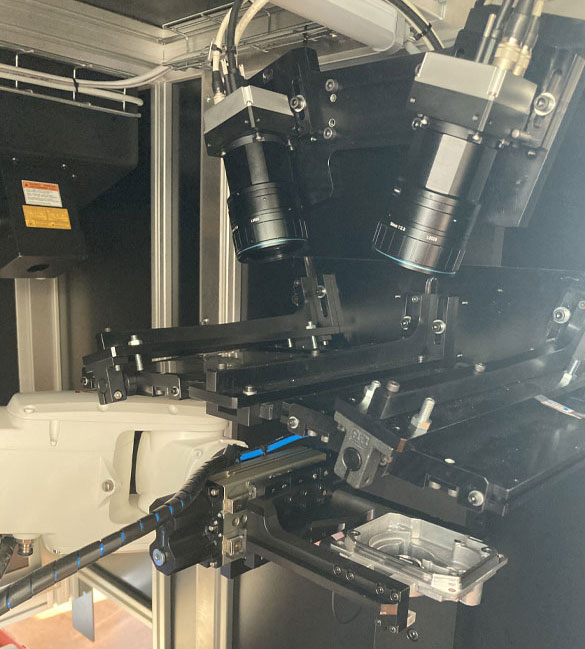

qmt offers turnkey solutions for aesthetic inspection of manufactured products. They integrate high-performance optics, mechanical integration, and advanced software.

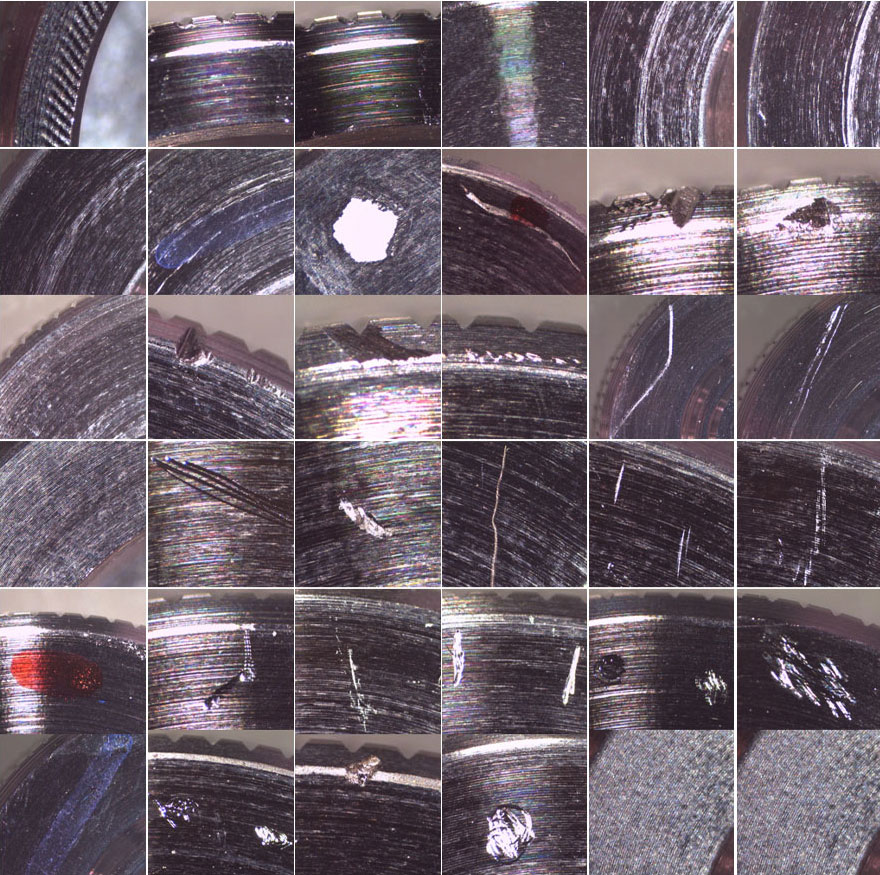

All aesthetic criteria can be automatically checked: defect detection (scratches, impacts, burrs, etc.), surface characterization (texture, uniformity, etc.) and measurement of perceived color.

QMT solutions are simple to implement, scalable, and customizable. Implementation is based on support using standard methodology and machine learning through artificial intelligence.

We contribute to our clients' development for lasting prosperity

Through vision, through hearing, through automated solutions integrating artificial intelligence, qmt limits the number of imperfections in what will or can be manufactured.

About qmtA team deployed across our two sites in Geneva and Chambéry

With our extensive know-how, we build a reliable partnership with our clients to develop solutions and support their success by improving quality and efficiency.

The qmt teamWe will never achieve perfection, but we work towards it every day.

qmt developed the Multimicro in 1991 (motorized image analyzer with automatic microhardness measurement), which was awarded a Credit Suisse prize. In 2015, qmt won the Geneva Canton Innovation Prize.

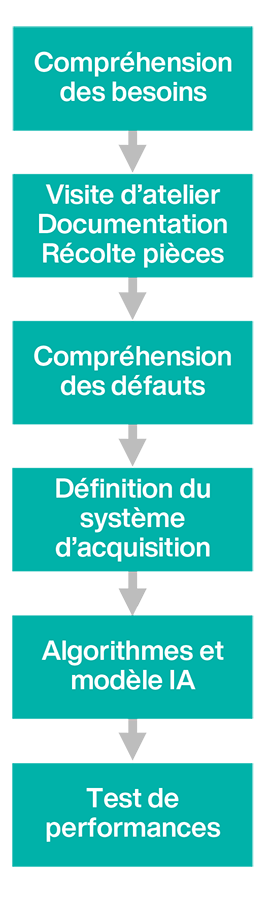

HistoricalA standard approach

- Project and process management including formalization

- Understanding Reference Control

- Development of the acquisition solution

- Development of the algorithm

- Creating the AI model

- Performance Test

- Availability to allow qmt to understand control

- Collection of parts and their qualification

- Qualification check after automatic assessment (verification)

Standard products for dimensional control

Customizable solutions to perfectly meet your needs

Tailor-made solutions created based on customer specifications

Aesthetic checks with linear cameras for the company Sonceboz

Dressing check

Machined metal parts inspection stations

Aesthetic control with artificial intelligence

The efficient and easy-to-implement measure

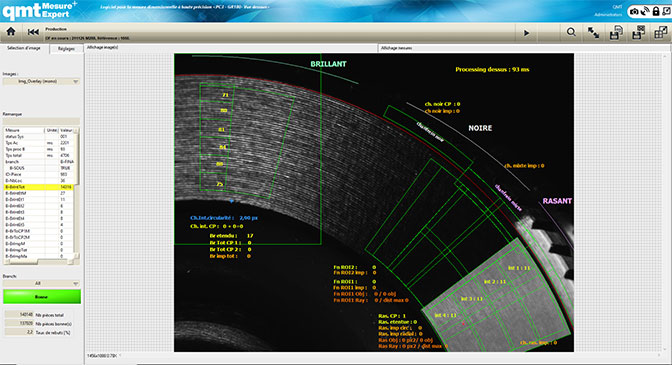

QMT software for standard products and custom developments. It is based on the latest technologies and has a very intuitive user interface.

- Ease of use with program creation wizards

- Library of business measurement functions including Artificial Intelligence

- Ability to customize to meet specific needs

- Centralized multi-device data management

- Centralized multi-device data management

- Efficient communication & synchronization with machines