qmtcolor

Measuring perceived color

Objectively control the color of components

To meet the needs of luxury markets, qmt developed qmtcolor technology to measure perceived surface color so that color control can be objectively measured.

One of the key features of qmtcolor technology is its ability to perform comparative color measurements on any type and size of surfaces. The instrument's high-speed optical system allows repeatable measurement of up to 8 zones simultaneously. In addition, it is possible to apply pixel pre-filtering to each area in order to select the pixels that you want to keep for characterization.

- Up to 8 simultaneous control zones

- Measuring area ranging from 0.01 to 20mm

- Integration of spatial variations with analysis and filtering of pixels retained for measurement

- Highlighting geometric variations of light with luminance histogram

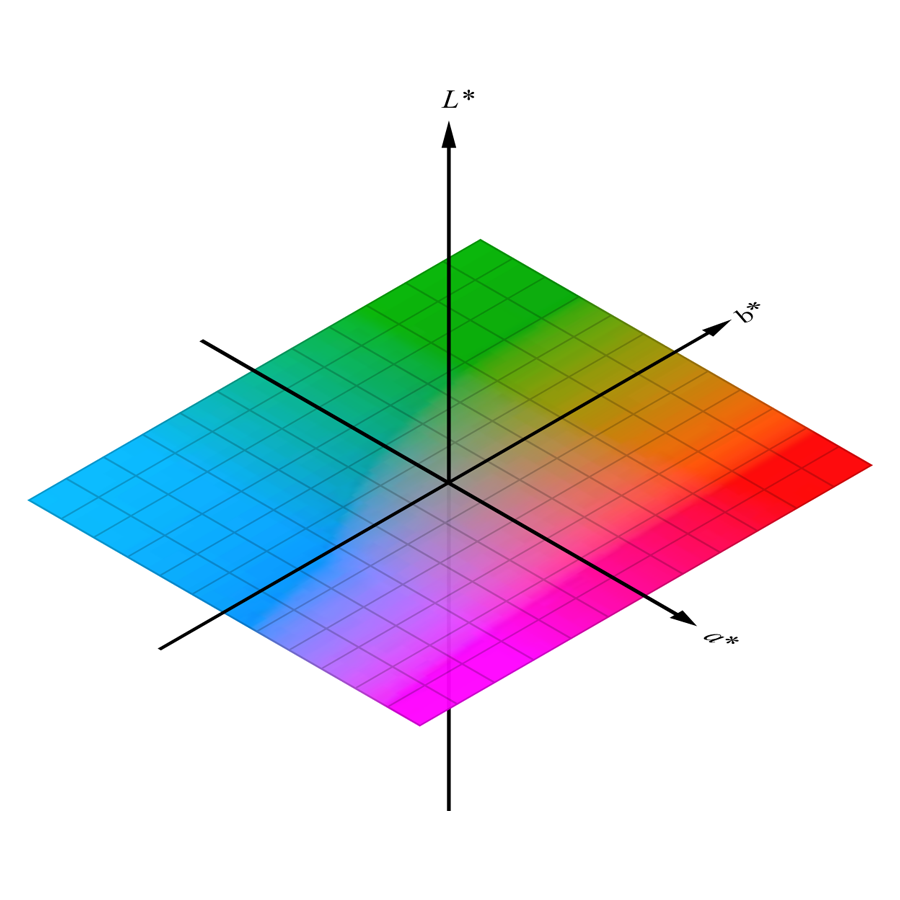

- 3D visualization of the measurement batch in a CIE76 L*a*b*C*h° representation

- Repeatability and reproducibility ΔE ≈ 0.6

Customizable solutions to perfectly meet your needs

Evaluation of perceived color

qmtcolor technologies

The qmtcolor is a device for characterizing the perceived color of manufactured products.

It is composed of a chamber with the optical system which allows reliable acquisition of information without influence from the outside world.

The qmtcolor is a polyavelent device which is suitable for use in production or in the laboratory.

The qmtcolor software is dedicated to this application. Interactive visualization of batch measurements in the lab sphere allows advanced evaluation for the operator

The measurement is carried out on a configurable surface (any geometry) with the possibility of averaging and filtering

Customization for advanced management such as automatic sending of results to databases

The qmtcolor incorporates a digital optical system that has been specifically defined to ensure sensitive and repeatable color measurement

Technology

The surface measurement of color

| qmtcolor | |

|---|---|

| Fields of vision | 10x10mm, 20x20mm, 30x30mm, 40x40mm, 50x50mm |

| Measurement area |

|

| Lighting | 2 configurable and switchable D65 daylight lights offering 20 different lighting possibilities depending on the desired effect

|

| Repeatability | ΔE ≈ 0.1 |

| Reproducibility | ΔE ≈ 0.6 |

| Time required for a measurement | < 1s |

| Type of measurable surfaces | All types of materials and finishes |

| Software | Different modes of use

Features

|

| Dimensions (H x W x D) [mm] | 450 x 440 x 240 |

| Item codes | AQ018AA001 |

More than 1000 systems have been delivered to a wide customer base since 1989

Customer SuccessCollaboration with Mr. Philippe Spay of newColor

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control