qmtservices-consulting

Expertise, studies and proof of concepts

QMT expertise for research and innovation

qmt has 30 years of experience in testing and quality control. Over the years, qmt has developed advanced and mastered expertise. With our TechLab, we have a leading infrastructure for innovation, research, and study execution.

We make all of these resources available to our clients to carry out studies, research and proof of concepts.

- Technology Evaluation for a Typical Application

- Defining the performance of a system to verify its suitability for a need

- Technology comparison

- Expertise to improve the performance of an existing system

Implementation of Proof Of Concept (POC) for aesthetic control

Infrastructure for QMT research and customer studies

To meet its clients' needs in quality control and automated testing, qmt experts are sometimes required to conduct feasibility studies. Indeed, qmt offers its expertise only if the technical team considers the maturity of the technology and know-how necessary to meet the need to be sufficient. qmt refers to the ISO 16290 standard to define this maturity level (TRL: technology readiness level). If the level is not sufficient (less than 6 out of 9), the qmt Techlab is used by our experts to conduct feasibility studies necessary for the maturation of the know-how.

Our Techlab is equipped to meet the needs of both mature and new technologies.

- Traditional industrial vision equipment with a wide range of optics, lighting, cameras and an optical bench with associated optical assemblies

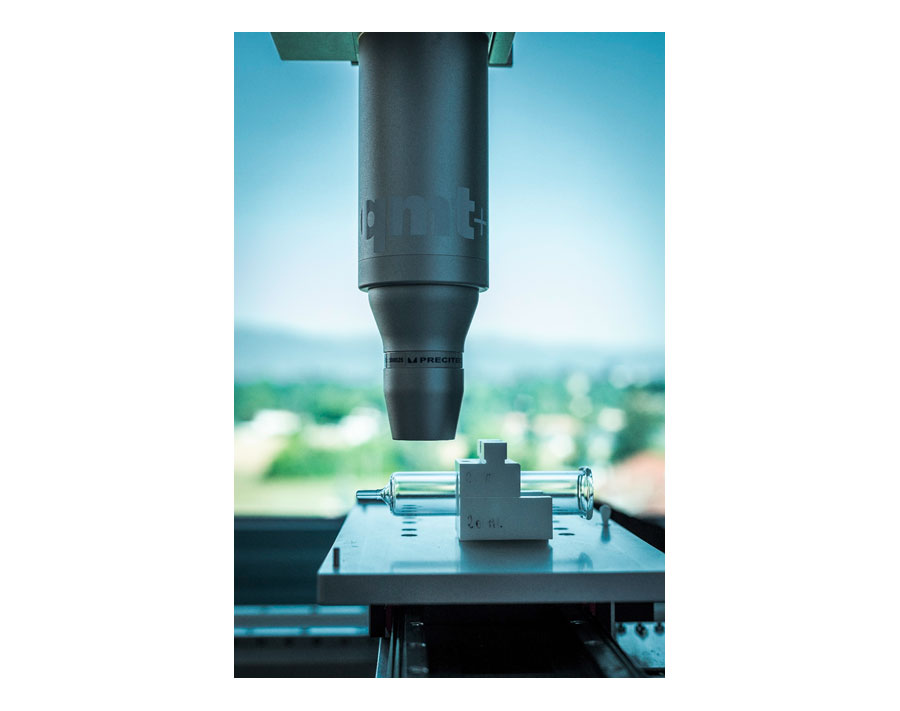

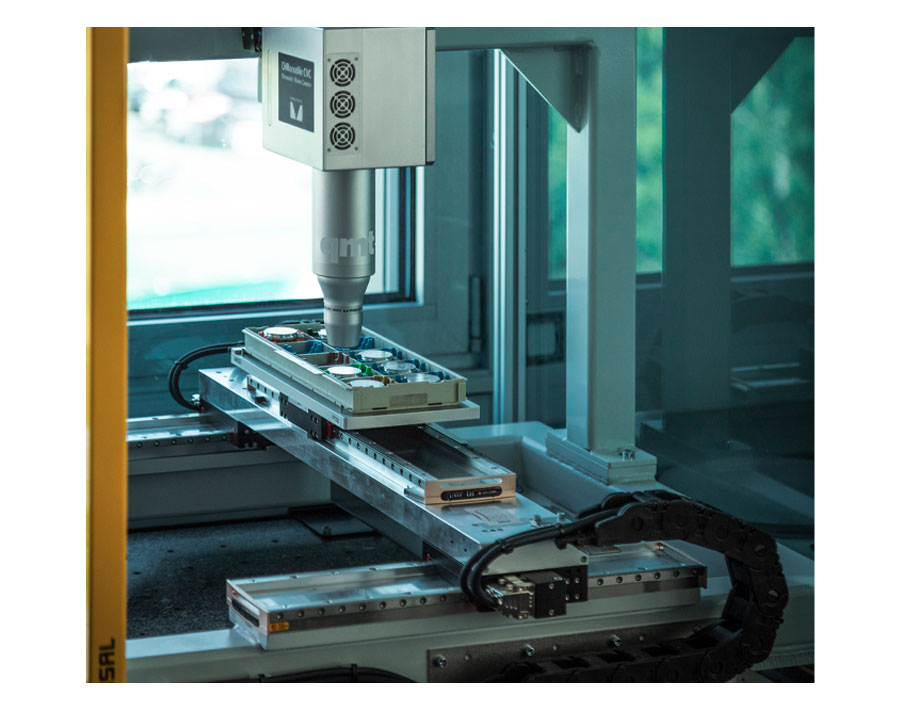

- Motorized bench equipped with chromatic confocal technology

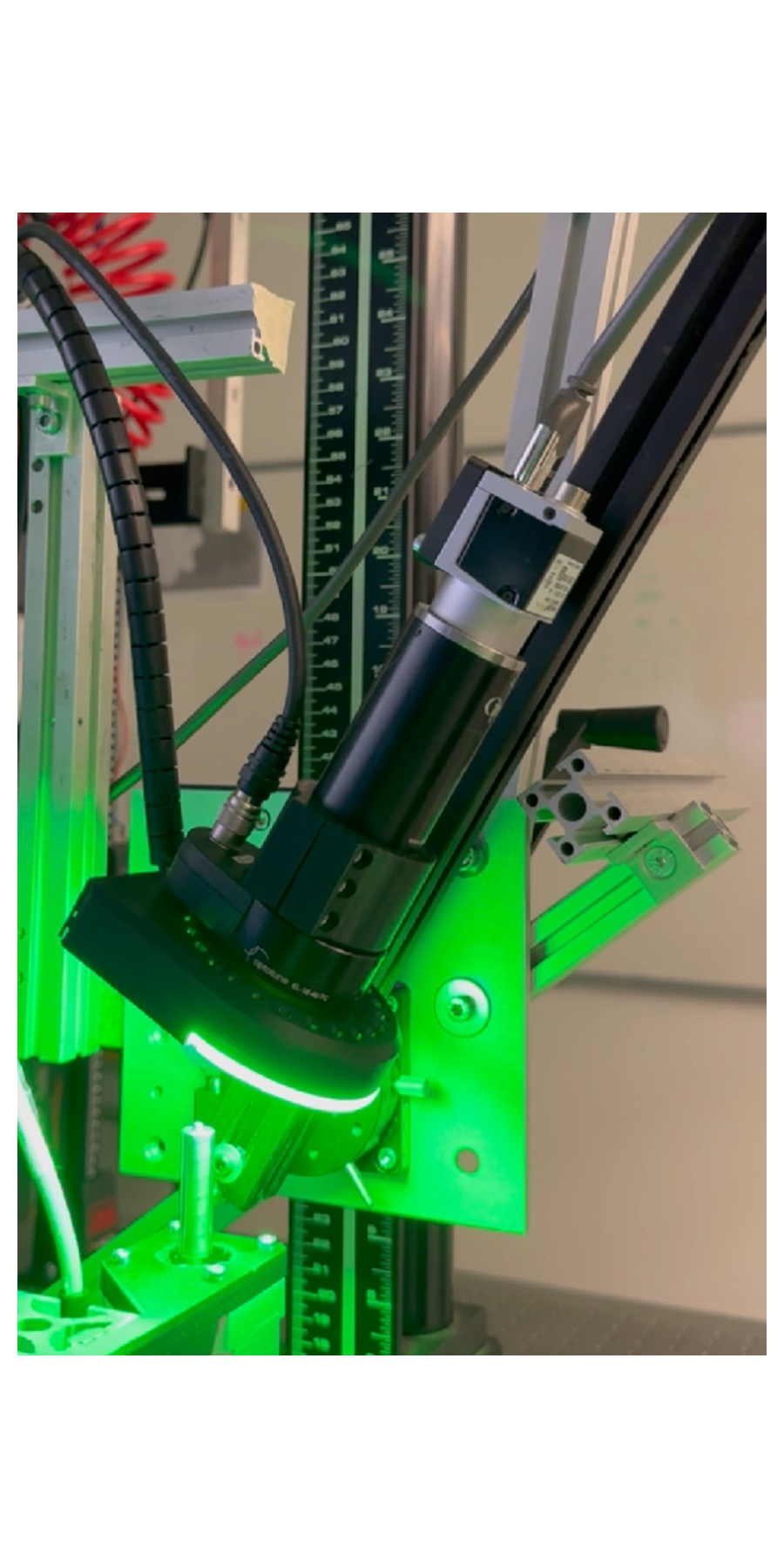

- qmtmultisens equipment allowing the combined acquisition of optical and acoustic signals

- Computer systems with analysis software

More than 35 years of history

A history marked by innovation. qmt developed the Multimicro in 1991, which received an award from Crédit Suisse (motorized image analyzer with automatic microhardness measurement). In 2015, qmt won the Geneva Canton Innovation Award.

Our historyMotorized bench with chromatic confocal measurement technology

Chromatic confocal technology for optical distance and thickness measurement has been adopted as a proven method in industry and research. It is a perfect complement to traditional optics for in-plane measurement.

We have equipped our Techlab with a CVC (CHRomatic Vision Camera) sensor. The CHRocodile CVC line scan camera uses chromatic optics for 2D imaging. Chromatic confocal technology allows for both a significantly greater depth of field than standard cameras and an extraordinarily high lateral resolution. Since it does not require focusing, this camera saves valuable time during quality inspections. By ensuring high contrast on all types of materials, the CVC CHRocodile is ideal for inline or offline applications, such as cosmetic inspection and positioning detection.

By ensuring high contrast on all types of materials, the CVC CHRocodile is ideal for in-line or offline applications, such as cosmetic inspection and positioning detection.

- Linear motor axes with precision ball bearing guides, self-lubricating with large distance between guide rails for high torques

- Magnetic measuring system; resolution 1μm, accuracy +/- 8μm and reference marks for absolute position

- Stroke 320mm, Fn 60N, Fp 180N in X and Y, and 160mm in Z

- Robot guidance

- 3000μm depth of field, 5.88mm scan line length

- Lateral resolution of 2.9μm; a maximum number of pixels of 2048

- Possibility of adding 3D measurement on the same optics

Fabrice Seyve and Claude Détée are ready to meet your needs in transparent part inspection, thickness measurement, or 3D characterization. Your parts will undergo our usual feasibility studies in our TechLab in Plan-les-Ouates or Barraux.

More than 35 years of history

A history marked by innovation. qmt developed the Multimicro in 1991, which received an award from Crédit Suisse (motorized image analyzer with automatic microhardness measurement). In 2015, qmt won the Geneva Canton Innovation Award.

Our historyQMT know-how for the implementation of solutions

Development of intuitive and high-performance industrial software including Artificial Intelligence

Multi-physical measurements (torque, force, speed, position, etc.)

Intelligent Data Management and Artificial Intelligence

More than 100 customers have trusted qmt

- Affolter Technologies Malleray - Switzerland

- Audemars Piguet Le Brassus - Switzerland - testimonial

- Atokalpa Alle - Switzerland

- BONINCHI SA Meyrin - Switzerland

- CLA Clinical Laboratory Automation SA Delémont - Switzerland

- DUBOIS DEPRAZ Le Lieu - Switzerland

- IWC Schaffhausen Schaffhausen - Switzerland

- Jaeger-LeCoultre Le Sentier - Switzerland

- Jean Singer La Chaux-de-Fonds - Switzerland

- KIF Parechoc Le Sentier - Switzerland

- LA PIERRETTE Le Brassus - Switzerland

- Metalor Neuchâtel - Switzerland

- OMEGA Bienne - Switzerland - testimonial

- PANERAI Neuchâtel - Switzerland

- PATEK PHILIPPE Geneva - Switzerland

- Piaget Geneva - Switzerland

- SVM Micromechanics Villeret - Switzerland

- Swatch Group (various industrial companies) Switzerland, France and Thailand

- Valfleurier Buttes - Switzerland

- VOH Courtelary - Switzerland

- Baud Industries France, USA, Poland and Mexico - testimonial

- Borg Warner Eyrein - France

- Bontaz-Centre Marnaz - France

- CGR PMPC Besançon - France - testimony

- CODEC SA Dombresson - Switzerland

- Continental Automotive Switzerland Rüthi - Switzerland

- Demidec Marignier - France

- DOW Europe Horgen - Switzerland

- DuPont de Nemours International Geneva - Switzerland

- EFI Automotive

- Federal Mogul

- G. Cartier Technologies Cluses - France

- HID Global Switzerland Granges (Veveyse) - Switzerland

- HPO Scientrier Group , Cluses - France - testimonial

- Joseph Martin Vougy - France - testimony

- Kartesis Marignier - France

- Kuk Electronik Appenzell - Switzerland

- LEM Geneva - Switzerland - testimony

- Minesco - France

- NTN-SNR Annecy - France

- Pernat Emile Marignier - France - testimony

- POLYDEC Bienne - Switzerland - testimony

- Poppe + Potthoff Scionzier, Bonneville - France - testimony

- Raymond Dubosson Cluses - France - testimony

- Robert Bosch Automotive Rodez - France

- SONCEBOZ Sonceboz - Switzerland

- Valeo

- CFF SBB Bern - Switzerland

- CIMES Valenciennes - France

- Hitachi Energy Geneva - Switzerland

- Sécheron SA Geneva - Switzerland - testimonial

- Speno International Geneva - Switzerland - testimonial

- Aleva Neurotherapeutics SA Ecublens - Switzerland

- Allergan Medical Ecublens - Switzerland

- Becton Dickinson Medical Le Pont de Claix - France

- Cytiva SA Nyon - Switzerland

- Flextronics Solothurn - Switzerland

- Forteq Nidau Nidau - Switzerland

- Hamilton Company Reno - USA

- Heraeus Materials Yverdon-les-Bains - Switzerland

- Johnson & Johnson Le Locle - Switzerland

- IMA Medtech La Chaux-de-Fonds - Switzerland

- Kyphon Medtronic Galway - Ireland

- Maillefer Instruments Ballaigues - Switzerland

- Medtronic Switzerland, Puerto Rico, Singapore

- Nolado Treff Degersheim - Switzerland

- Nypro Healthcare Knittlingen - Germany

- Suturex & Renodex Sarlat - France

- Zubler AG Uzwil - Switzerland

- Bobst Prilly - Switzerland

- BTG Eclepens Eclepens - Switzerland

- Ebnat Kappel Ebnat - Switzerland

- Europipe Dunkirk - France

- Firmenich Geneva - Switzerland

- HID Global Switzerland SA Granges (Veveyse) - Switzerland

- Jokey - Germany, France, Canada, Belarus

- LN Industries Champagne - Switzerland

- Metalor Technologies Courville-sur-Eure - France

- Nestlé Lausanne - Switzerland

- Novartis Basel - Switzerland

- Philip Morris Lausanne and Neuchâtel - Switzerland

- Profalux Thyez - France - testimonial

- Rollvis Geneva - Switzerland

- Somfy

- STMicroelectronics

- Staubli