QMTWheeltest-Vision

Control of rotating clock mobiles

Equipment for measuring beats and splits

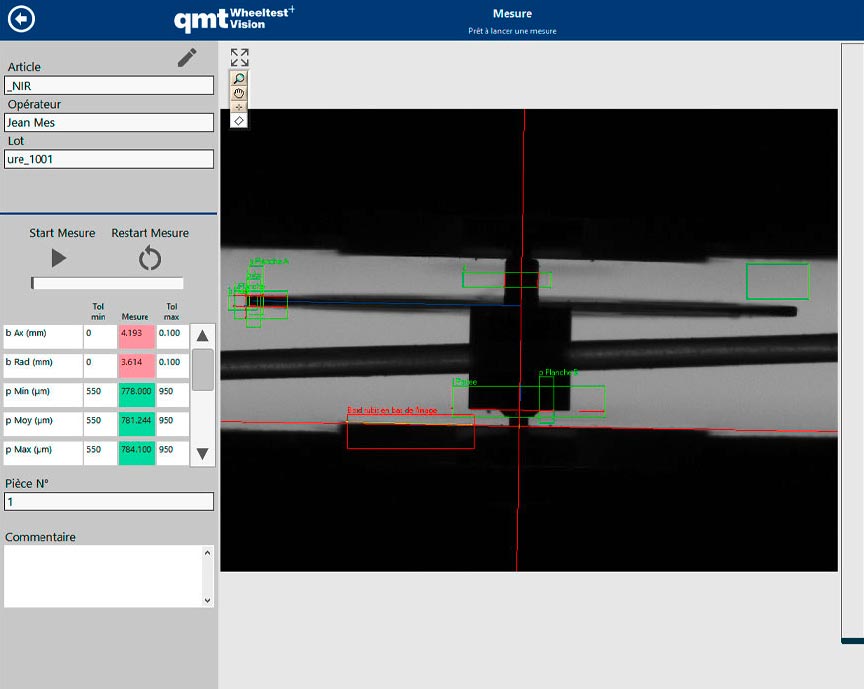

During the measurement, the values are displayed instantly in the graph according to the progress. After several wheel cycles (defined duration), the results are displayed and indicate whether the measured part is compliant or not compliant (OK/KO). Batch management, report editing and the interface with statistical software allow optimal integration of the equipment into a quality process. The QMTWheeltest-Vision can also be personalized thanks to the “Fit For You” program.

- High-accuracy dynamic measurements of beats and splits

- Ease of use with binocular to position component and intuitive software

- Five training devices to measure all types of components

- Two measurement modes for laboratory and production

Customizable solutions to perfectly meet your needs

Available for rental

- Delivery within 4 weeks

- Commissioning and training by qmt

- Flexible rental period per monthly period (no commitment)

- Preventive maintenance and calibration are performed by qmt annually

- Possibility of acquiring the equipment after rental

Measurement for production

An optical inspection device

qmtwheeltest-vision technologies

The qmtwheeltest-vision is a device developed by qmt to meet the specific needs of measurements in the microtechnical fields and in particular watchmaking.

The qmtwheeltest-vision has an optical system that acquires the image of the whole part at high resolution and high speed to allow dynamic measurement.

The binoculars integrated into the qmtwheeltest-vision facilitate the removal of the components on the mountings

With the telecentric lens, the high resolution camera

Dedicated software for measuring beats and splits for optimal intuitiveness

A configurable export module allows the creation of a personalized configuration without having to make a new version of the software

Rotation of the part for dynamic measurement. With the 5 mountings, all the components can be controlled: mobiles, boards, sprockets, ...

More than 1000 systems have been delivered to a wide customer base since 1989

Customer Success

Wheeltest 1

- 2 parallel jaws in ruby with 1 notch in "Vé", prof. 0.9 mm, angle 90 °, th. 0.6 mm

- Jaw spacing adjustment by μ-metric screw with 0.25 mm pitch fitted with return springs

- Adjustment of the height of the movable jaw by screw and return spring

- Speed adjustment from 9 - 22.3mm / sec (0.5 to 2.3mm / sec with reduced speed option)

Wheeltest 2

- Pins with 60 ° ruby point, adaptation of Azurea pegs and hollow pins

- Workpiece drive by rod, with grip between the arms of the board

- Spindle drive speed of the mobile 8.9 - 17.8 rpm

Wheeltest 4

- Taper spindle (15 °) of rotation (dia. 4mm) and support spindle (bore dia 2mm)

- Adjustment of the control position of parts to be measured by mechanical stop

- Spindle drive speed 16.2 - 32.5 rpm (1.5 - 3 rpm with the reduced speed option)

Wheeltest 5

- 2 parallel jaws in ruby with 1 notch in "Vé", prof. 0.9 mm, angle 90 °, th. 0.6 mm

- Jaw spacing adjustment by μ-metric screw with 0.25 mm pitch fitted with return springs

- Adjustment of the height of the movable jaw by screw and return spring

- Speed adjustment from 3.9 - 22.3mm / sec (0.4 to 2.2mm / sec with reduced speed option)

beat measurement

| Functions | QMTWheeltest-Vision | QMTWheeltest-Vision-F4Y |

|---|---|---|

| Fields of view [mm] | 9.1x6.8 | According to specifications |

| Accuracy [μm] | 2 | According to specifications |

| Time for a measure | < 5 seconds (single parts) | According to specifications |

| Binocular | When installing the component | According to specifications |

| Lighting | Diascopic and episcopic (installation of the component) | According to specifications |

| Measurement software | qmtwheeltest-vision | According to specifications |

| Focus (z axis) | Manual | According to specifications |

| Component drive | VOH Wheeltest drive systems 1, 2, 3, 4 and 5 (optional) | According to specifications |

| Computer science | External PC in Windows 10 | According to specifications |

| Dimensions (H x W x D) [mm] (without computer) | 420x330x335 | According to specifications |

| Item code | AQ005AA001 |