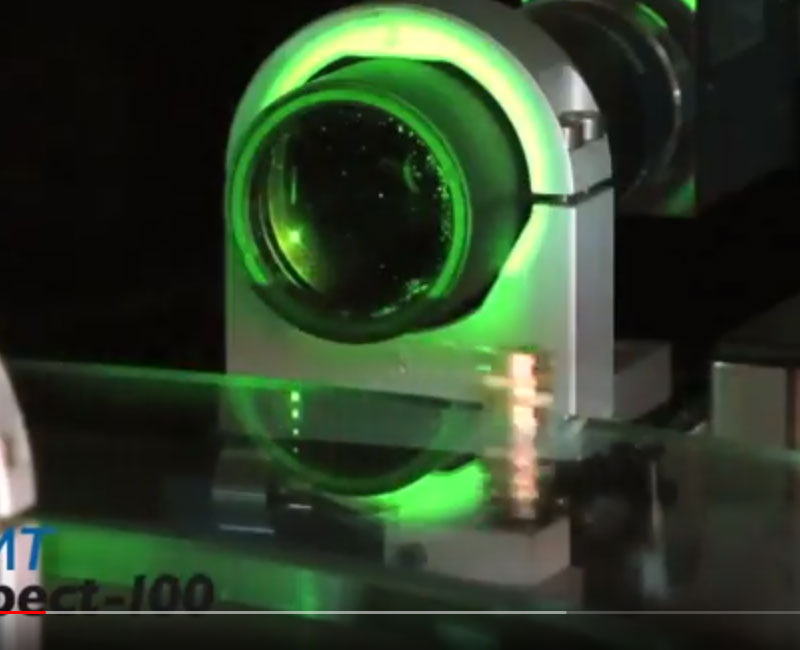

QMTInspect-100

Glass tray sorting machine

Control and sorting rotary table machine for cut or molded machined parts

The QMTInspect-100 is part of the QMTInspect range of sorting machines for the most demanding applications. The basic QMTInspect-100 includes two optical control stations to which 3 stations can be added from a choice of multiple options (optical, laser and pneumatic buffer). The QMTInspect-120 is a variant with an indexed chainring for unstable parts and for more controls.

This control machine benefits from the new range of QMTMesure software, for high precision dimensional measurements.

.

- Wide choice of control options including complex multi-camera controls

- Very high sorting rate

- The QMTSubFace aspect control and in particular the high sensitivity peripheral control

QMTInspect-100 end of life

Qualimatest has decided to end the collaboration with Prosys. As a result, the QMTInspect-100 is no longer sold.

More informationMore than 1000 systems have been delivered to a wide customer base since 1989

Customer SuccessQMTInspect-100

| Functions | QMTInspect-110 | QMTInspect-120 | QMTInspect-100-FFY |

|---|---|---|---|

| Handling of parts | Glass plate in continuous rotation | Table top with positions and indexed rotation | All types max 15 x 15 x 15mm |

| Type of rooms | Stable parts on one side, min 0.5 mm, max 50 x 50 x 50 mm | Unstable parts on one side, min 0.5 mm, max 80 x 50 x 50mm | Left parts |

| Materials | Metal, ceramic, mineral, plastic | Metal, ceramic, plastic | |

| Maximum rate [pcs / h] | from 3,600 to 36,000 pieces / hour | up to 3,600 pieces / hour | According to configuration |

| Vision control stations | Up to 5 stations of 4 cameras (all orientations) | According to configuration | |

| Control technologies additional | • Pneumatic buffer • Laser • Confocal sensor • QMTSound • Eddy current | • Pneumatic buffer • Laser • Confocal sensor • QMTSound • Endoscope • Eddy current | • Pneumatic buffer • Laser • Confocal sensor • QMTSound • Endoscope • Eddy current |

| Loading options | • Vibrating bowl | • Vibrating bowl • Centrifuge • Flexible power supply • Robot • Bulk packaging or trays | |

| Unloading options | • Several bins (management of non-compliant) • Automatic management of packaging (boxes, bags, etc.) • Robot • Unstacker | • Several bins (management of no compliant) • Automatic management packaging (boxes, bags, etc.) • Robot • Unstacker | |

| Dimensional measurements | Any type of measurement with an accuracy of up to 0.5 μm | According to specifications | |

| Presence / absence checks | Chips, chamfers, tapping, knurling, thickness Z | According to specifications | |

| QMTSubFace appearance controls | Surface condition (no shocks, scratches, stains, etc.) circumference and lower and upper faces | According to specifications | |

| Machine size (W x D x H) | 2m x 1.5mx 1.5m (without distribution and accessories) | 2m x 1.5mx 1.5m (without distribution and accessories) | According to specifications |

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control

Automated quality control

An example of automated quality control: checking the aesthetic quality of Corn Flakes after baking

reading