Actualités

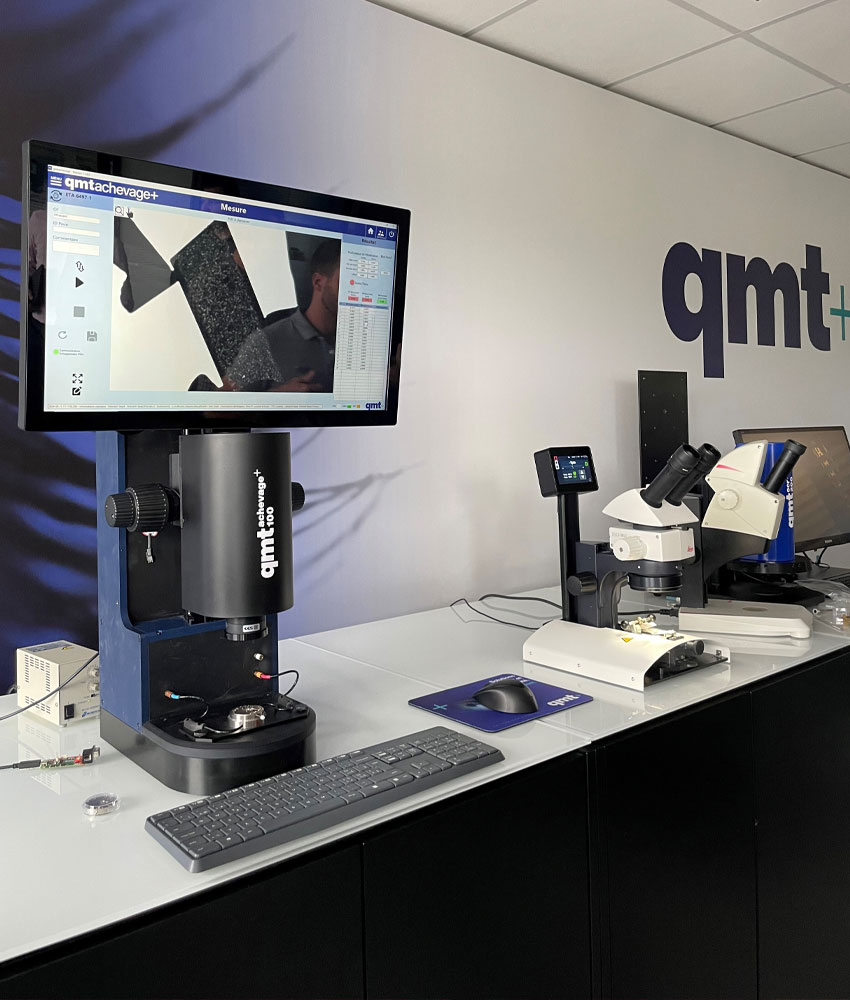

More performance with the QMTInspect-200 machine

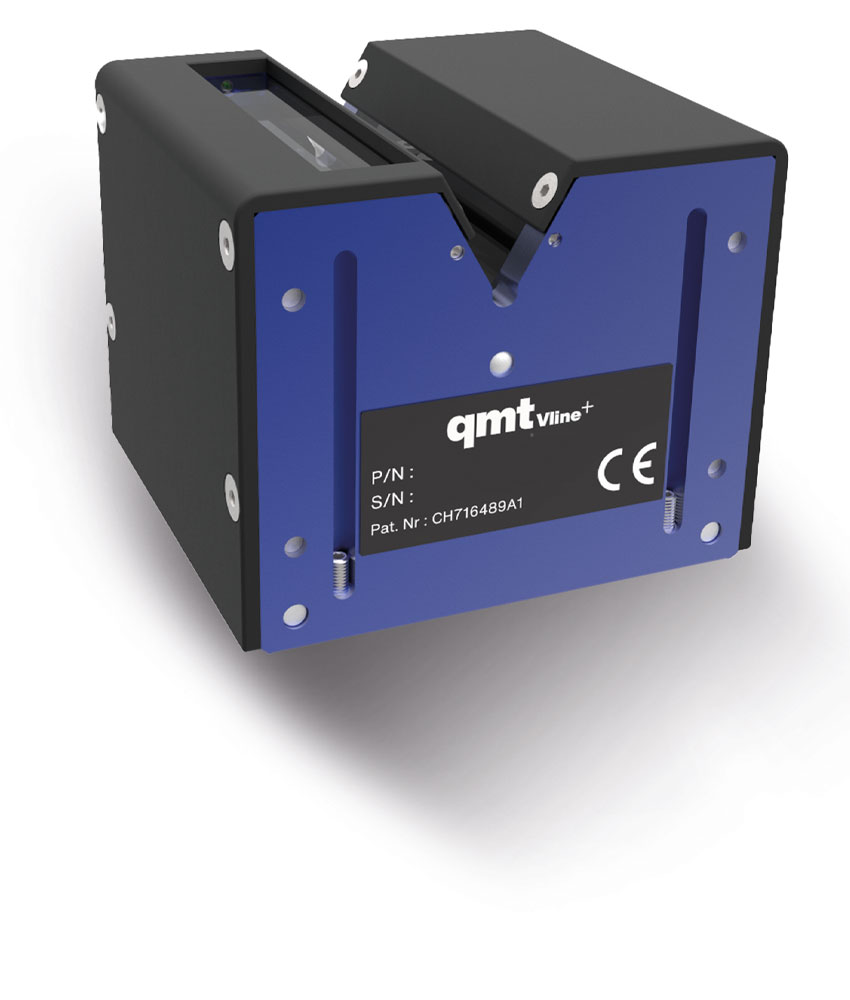

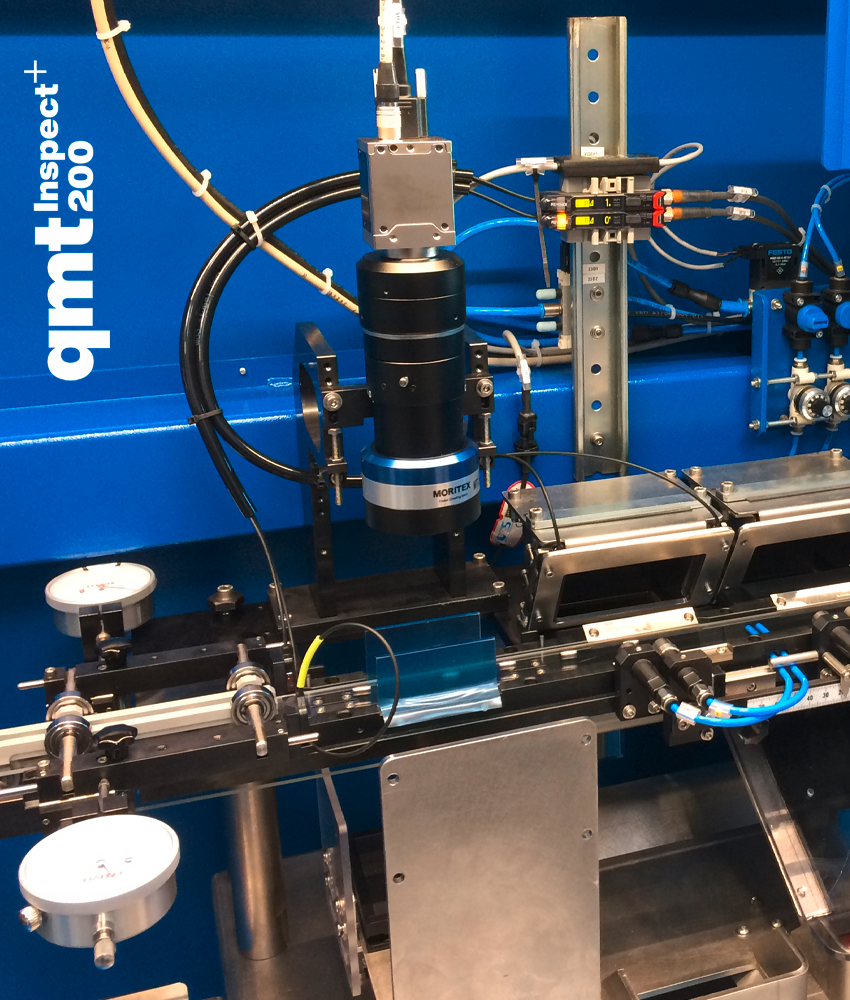

QMTInspect-200 for 100% sorting

New Features for the QMTInspect-200 Deliver More Performance and Flexibility

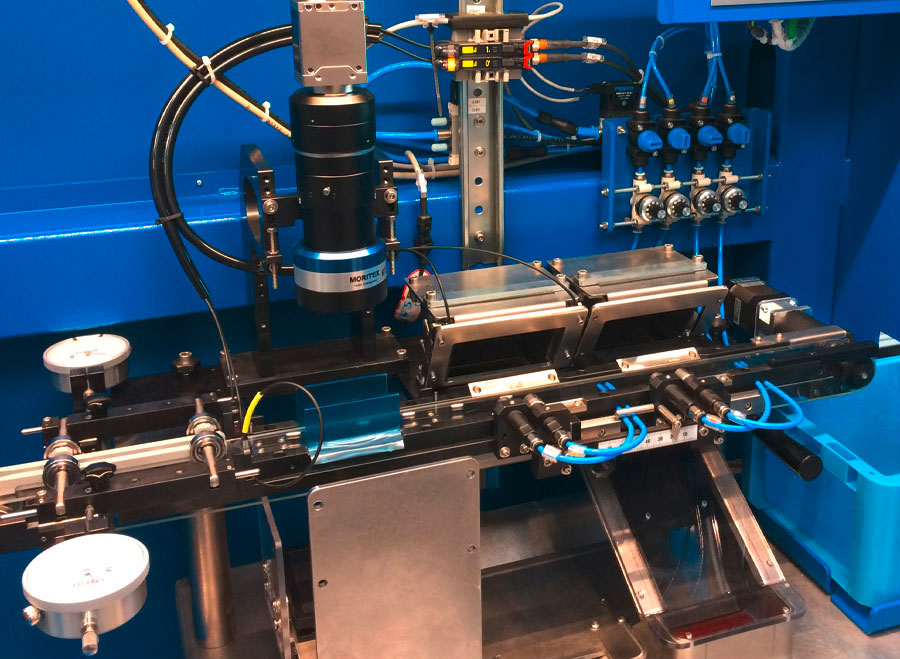

- New part control mechanics for more robustness and an increase in speed

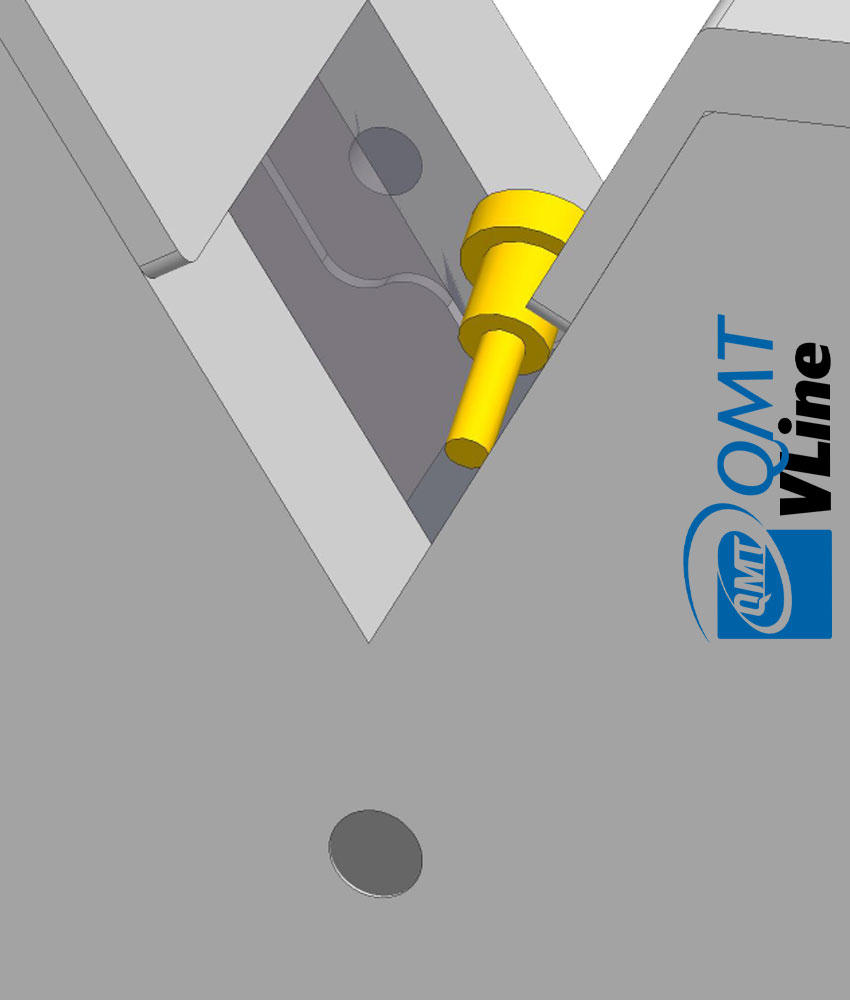

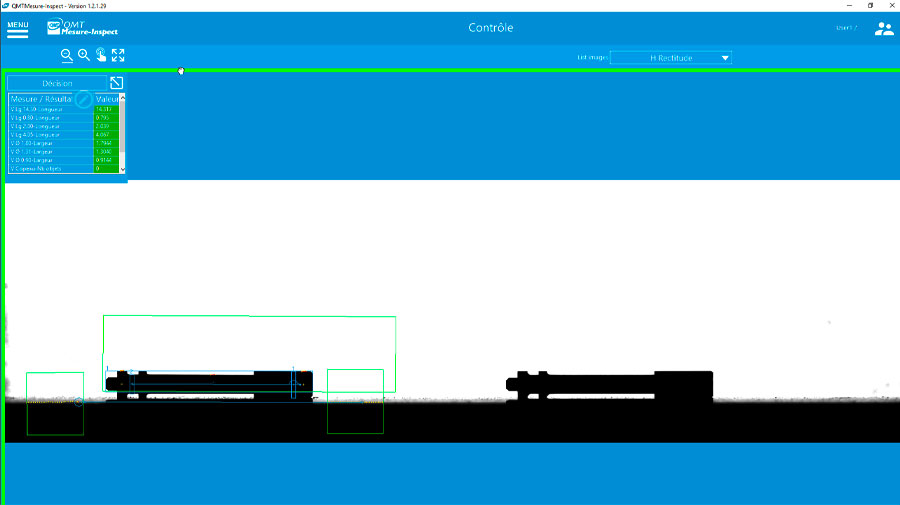

- A new horizontal view for measuring the straightness of parts

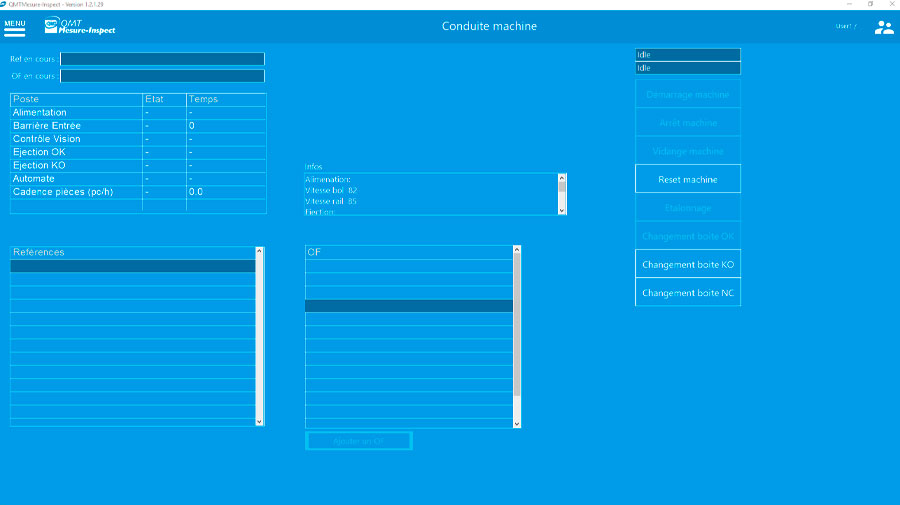

- New software for measuring and controlling the machine

The mechanics of the QMTInspect-200 have been completely redesigned to improve the handling of parts and allow much more precise adjustment. These modifications allow an increase in the rate of 50% (20,000 pieces per hour for pieces of 20mm length) as well as a reduction in the adjustment time when changing the reference.

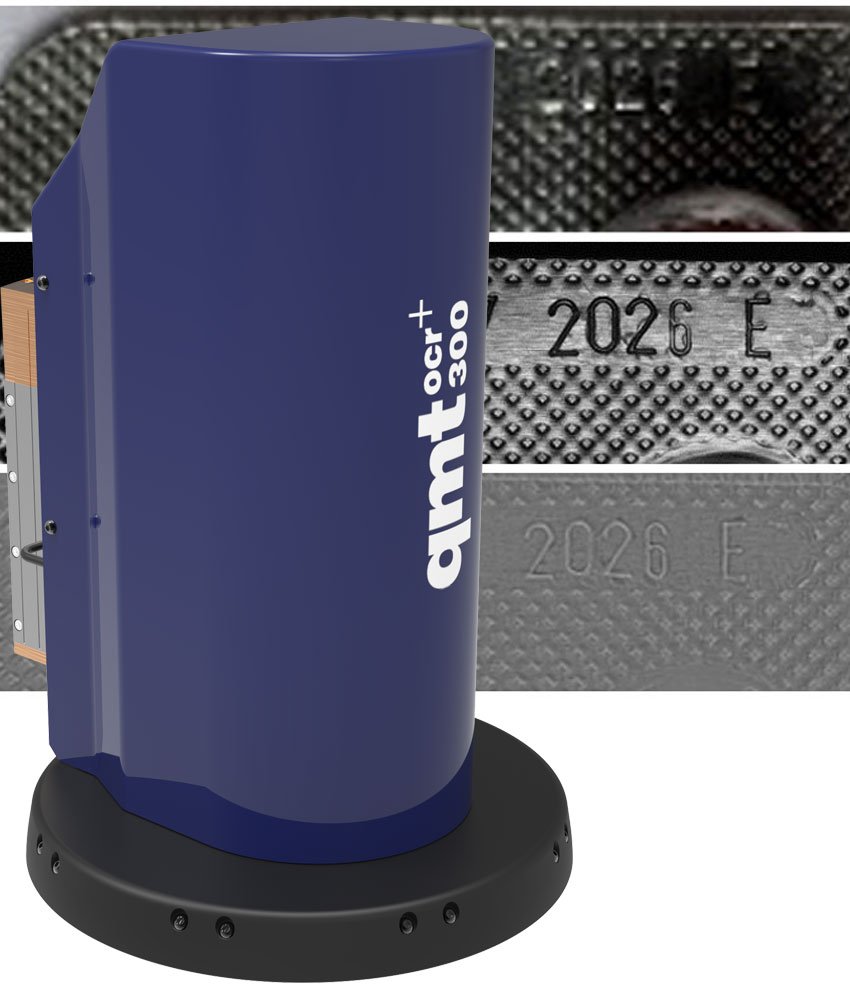

A new horizontal camera is available as an option to allow, in combination with the vertical camera, the measurement of the straightness of parts.

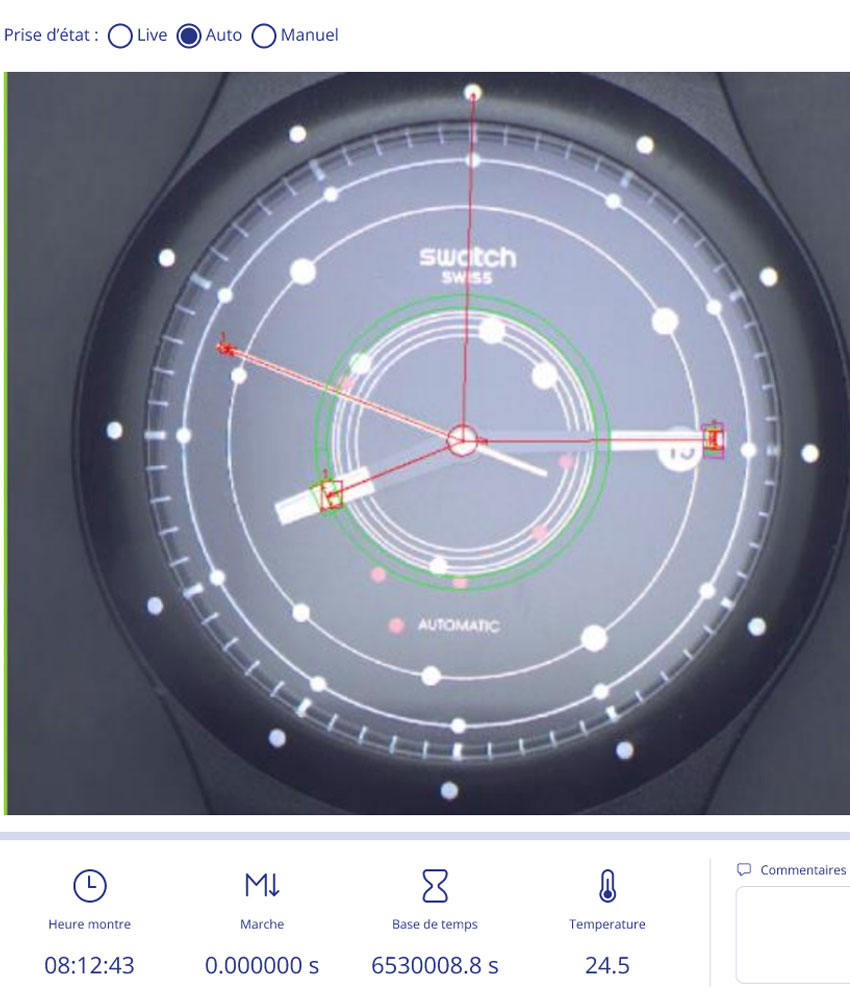

The QMTMesure-Inspect software has been developed to provide a single user-friendly interface for measurement and machine operation. It is thus possible with a single software to:

- create control programs from a metrological point of view and machine parameterization

- control the machines and display the states

- manage measurements

The part ejection mechanics have been completely redesigned to improve robustness and adjustments.