Actualités

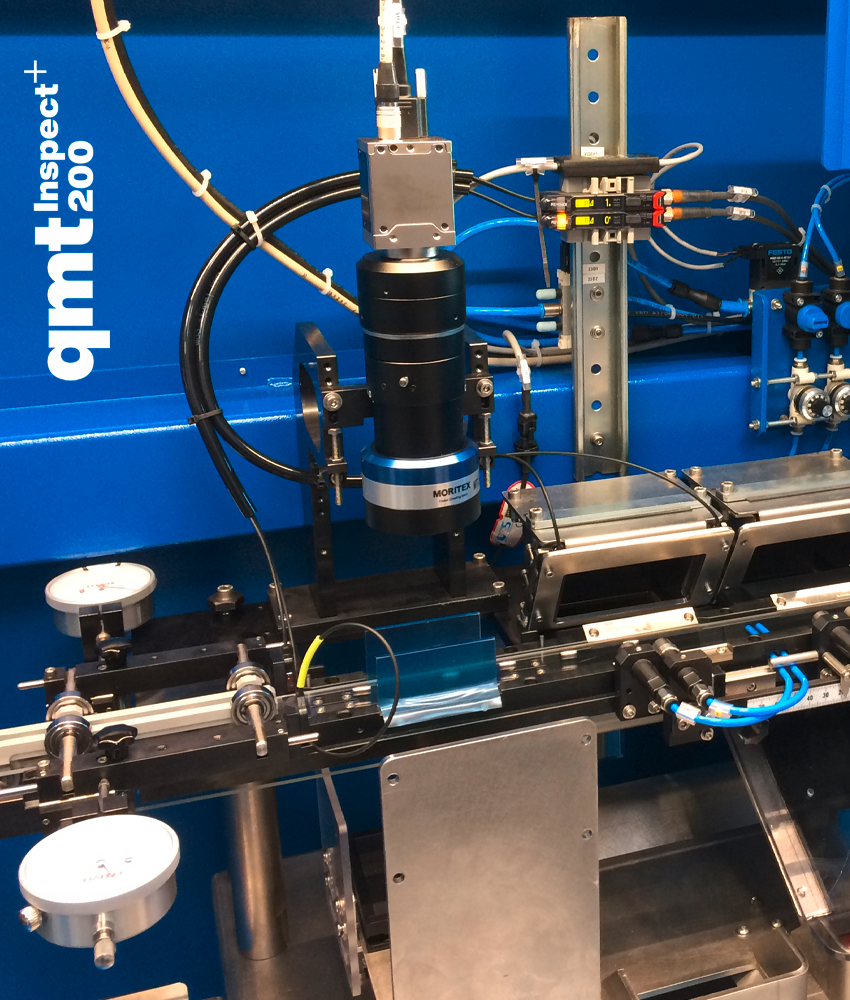

QMTCalqueControl: automatic dimension control functions over the CAD drawing of the part

Accessible QMTCalqueControl, a simple measurement solution without programming, quick to implement, flexible and for all

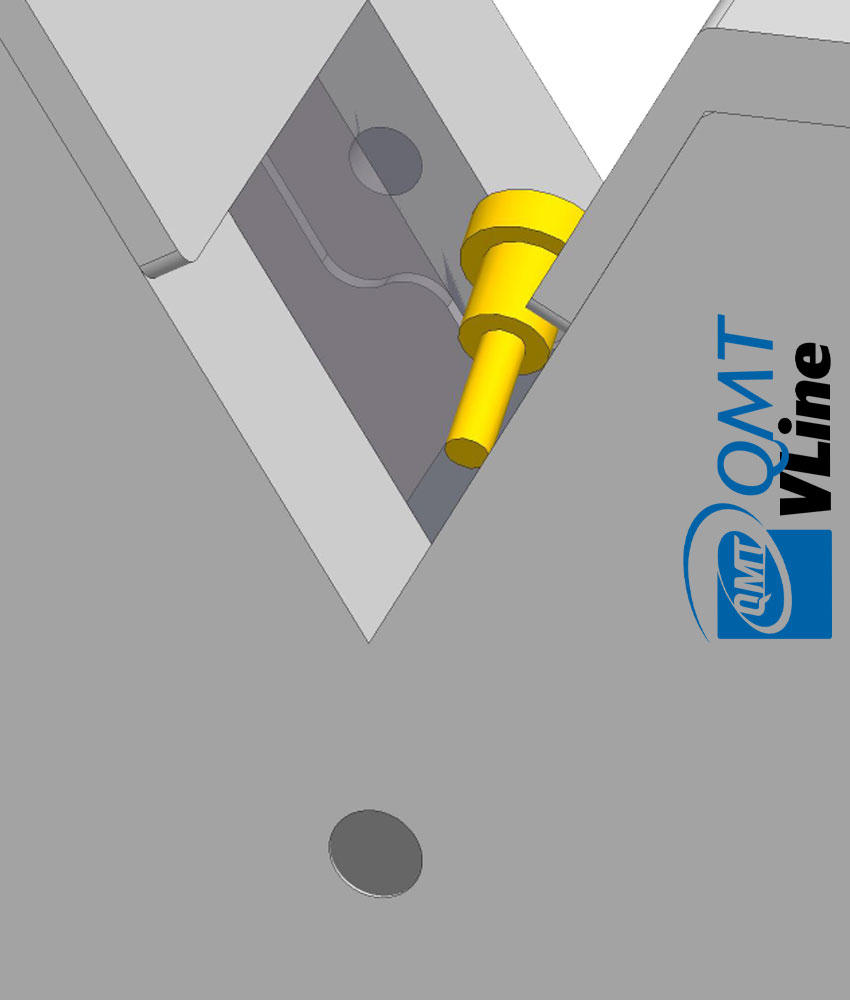

Quality control is often performed with profile projectors. Historically, the optical devices and the drawings of the parts on tracing paper. This measure was long and very precise. In the last 15 years, the use of computer systems is to simplify this control allows recorded by computer storage of part drawing on a digital image from a camera. Nevertheless, the orientation was "digital film" carried out on the game visually by the operator, where the risk of errors and lack of reproducibility.

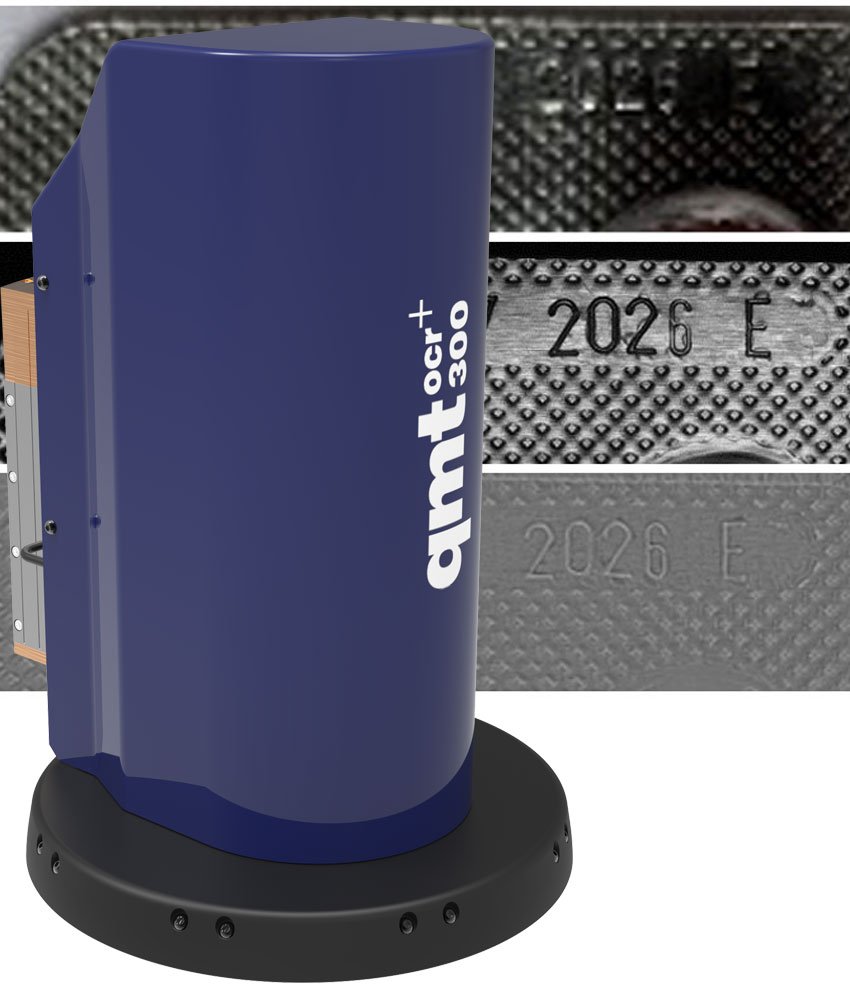

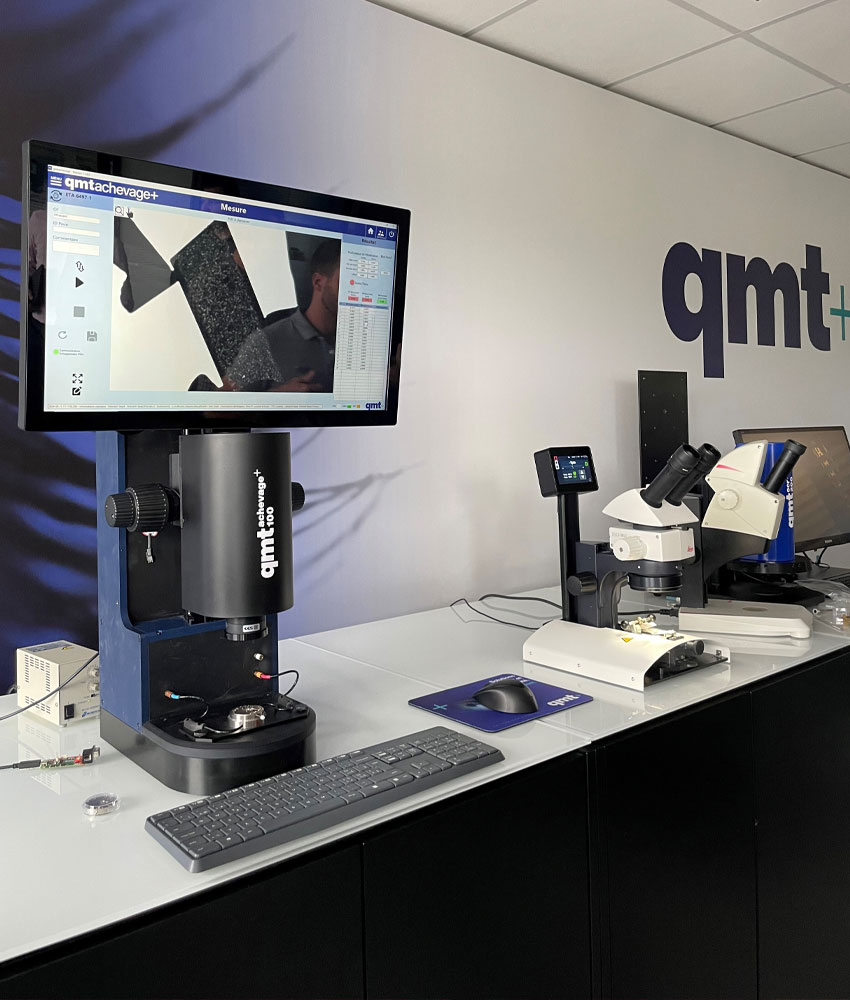

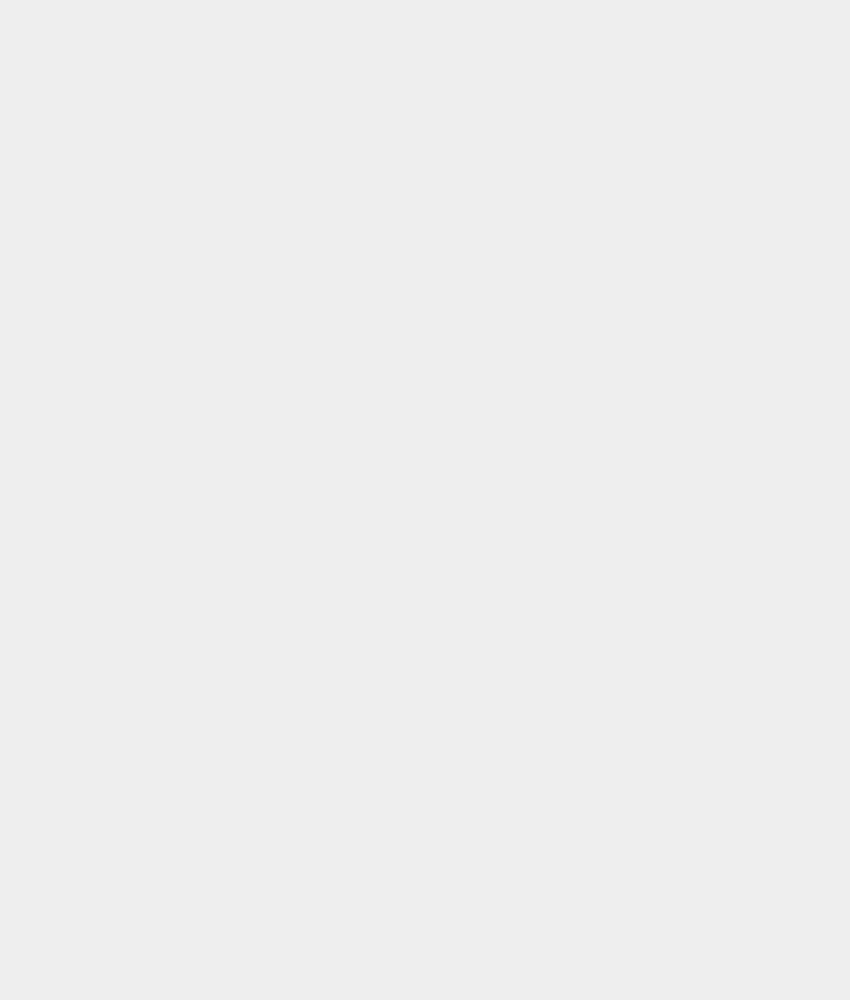

Qualimatest provides automatic quality control solutions, in particular measuring devices as WatchProjector. . In order to increase the effectiveness of monitoring, CAD file with the overlay detection and automatic alignment to the work piece since 2010. This progress has been suggested largely appreciated by the industry, but the final decision based on the visual gap remained controlling the court. A value of the gap was also the high expectations of users.

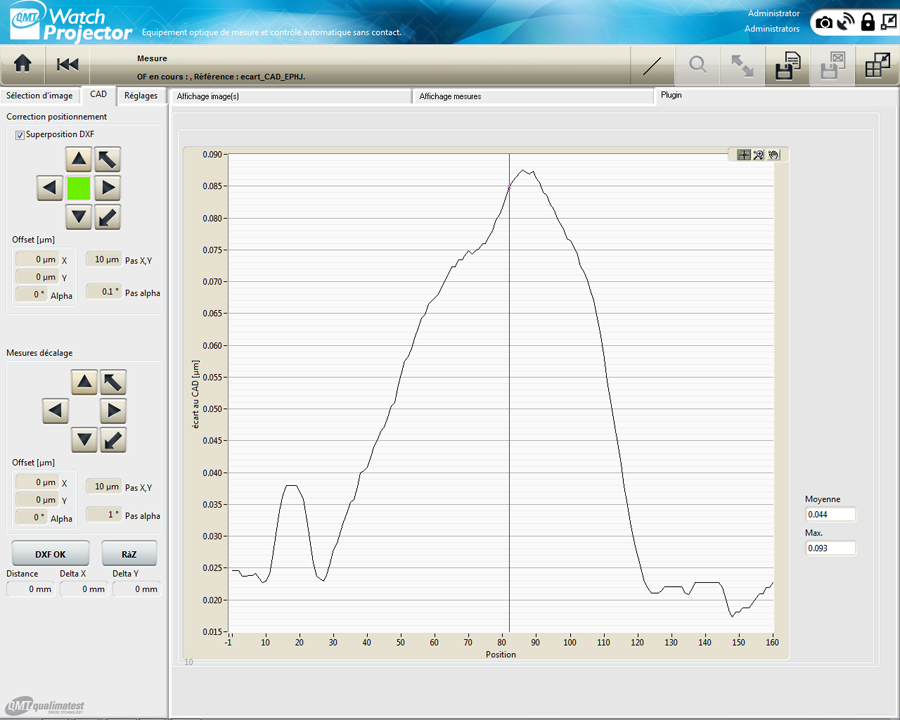

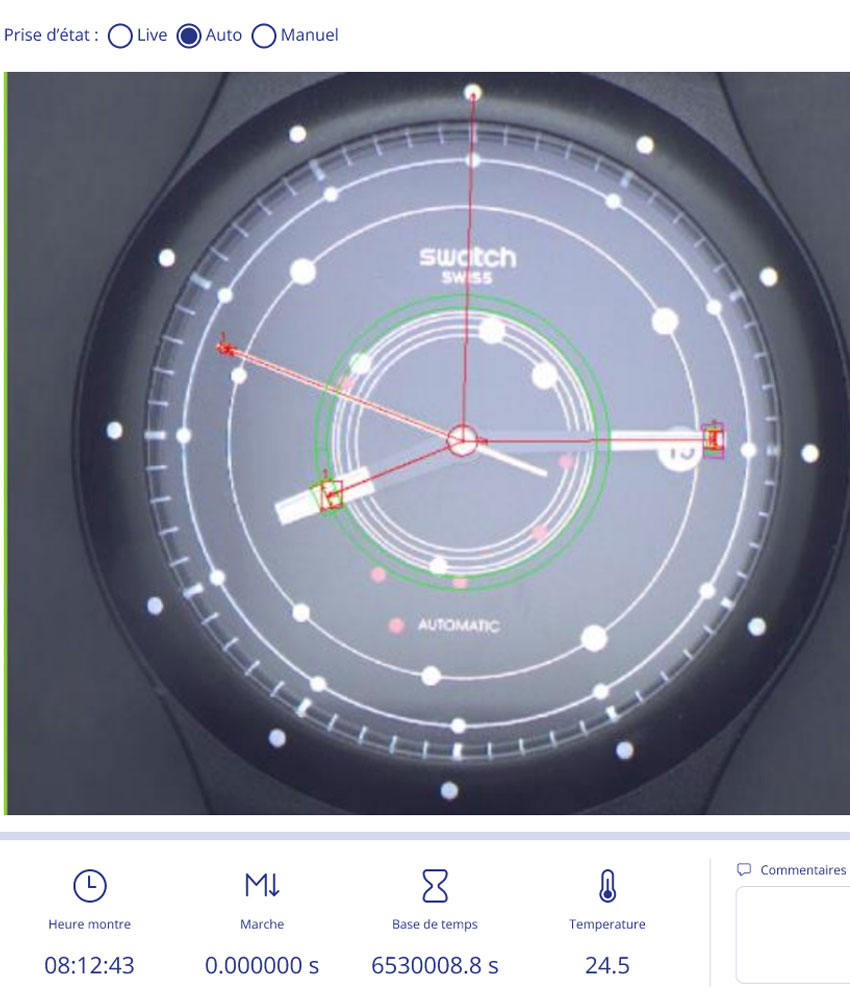

Example of a DXF overlay with decision by the operator

The new function is now in the QMTCalqueControl platform QMT visual confirmation cross, so to the range of solutions Qualimatest. It allows the automatic control by measuring the gap between the theoretical value of the plan and the actual value of the workpiece on the entire contour. It is now possible to control all of the geometry of a part quickly and automatically, without programming. A configurable filter system in order not to take into account, take small imperfections and dust suggested.

QMTCalqueControl includes:

- The decoding of the CAD file (DXF, PDF, ...)

- Automatic detection of the position of the piece for the precise alignment of the CAD drawing (more planing required)

- The measurement of the difference between the nominal value and the part is measured on all points of the contour

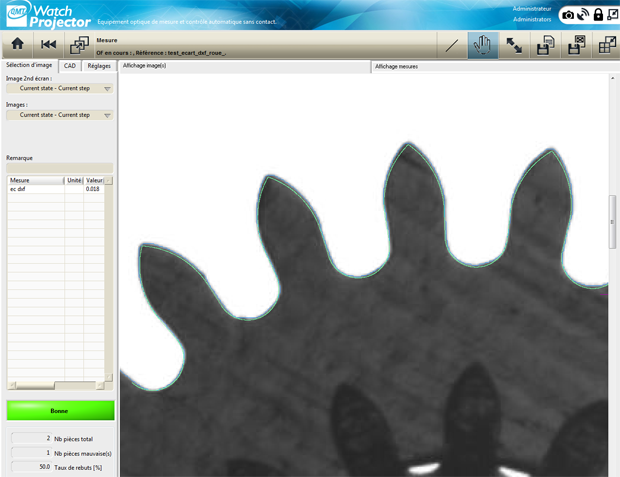

- Gradient A simple visualization of deviations from red to yellow

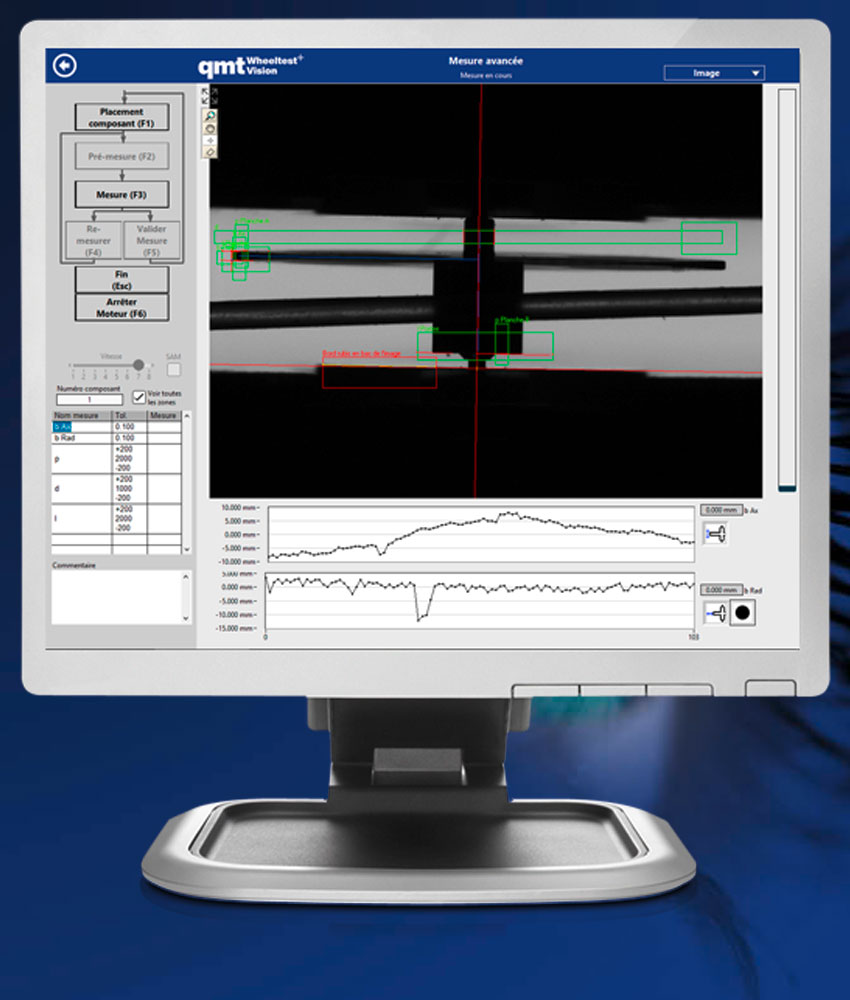

- The graphical representation of the deviation value curve over the entire length of the measured contour position interaction from image

- Filter results

- The decision OK / KO depending on the set tolerances

- A data archiving

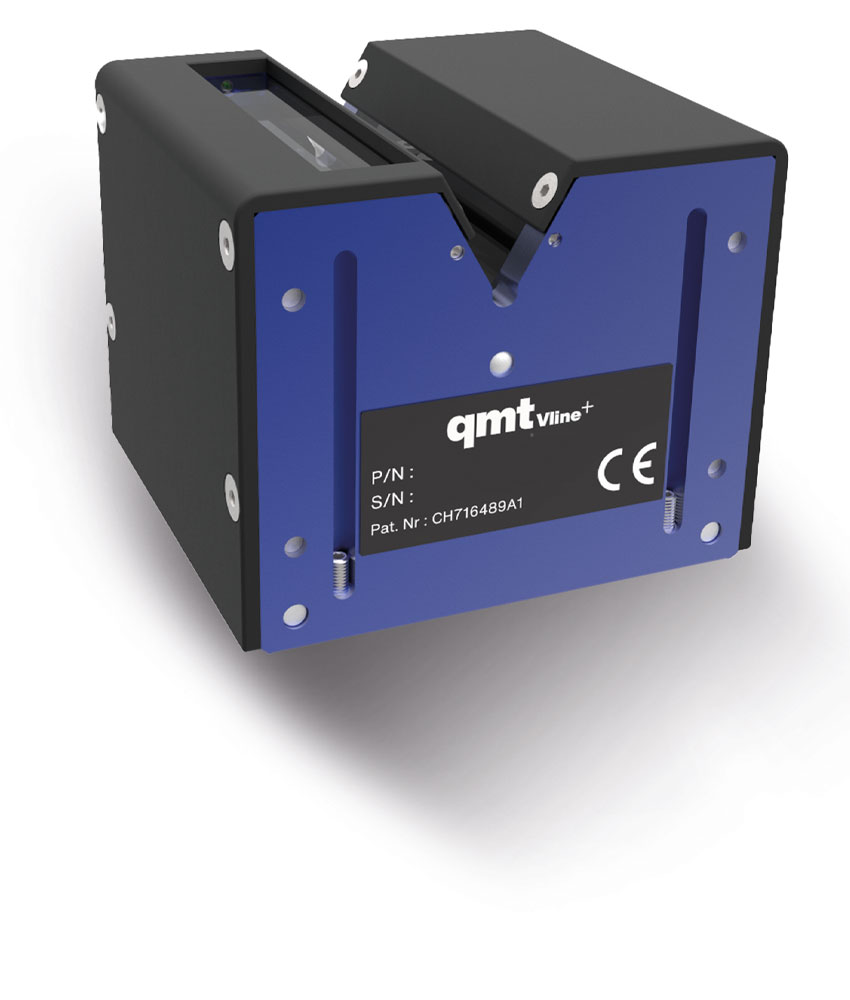

The measurement accuracy can achieve 1.6 microns, is depends on the optical configuration. QMTCalqueControl is particularly suited to the measurement device WatchProjector.

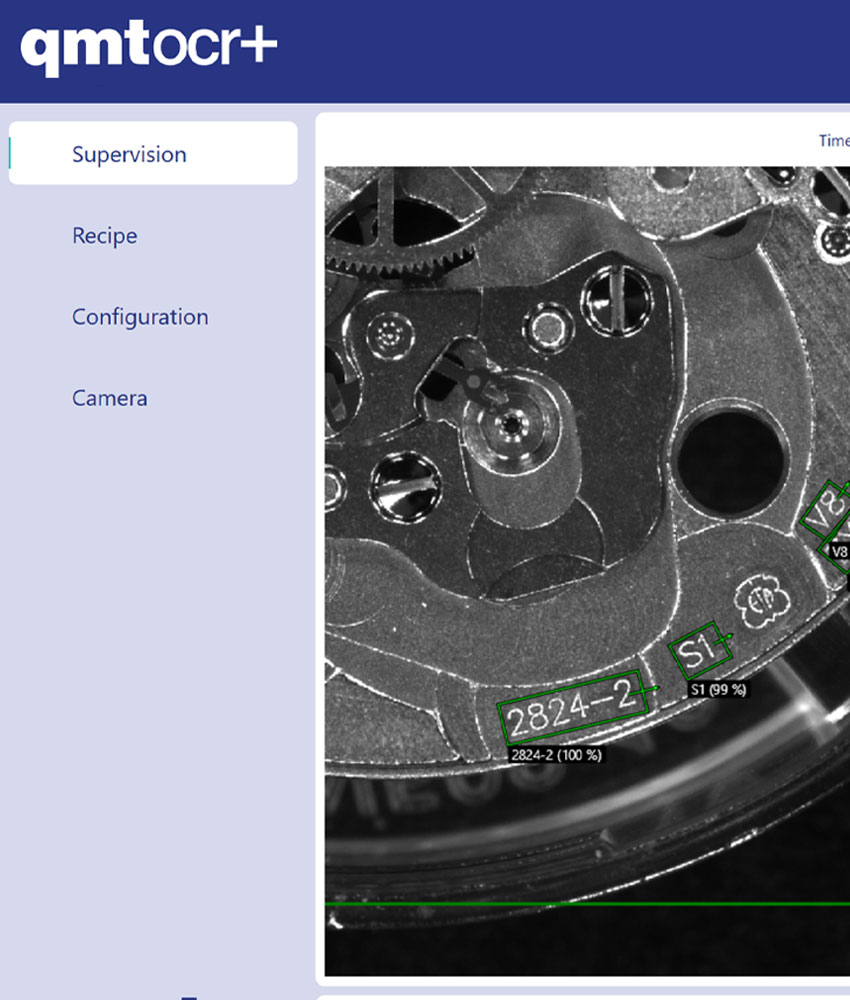

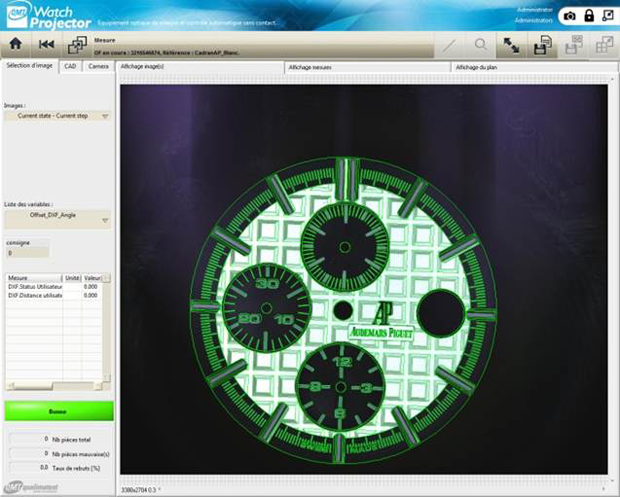

Example of control of a good part

Example of control of a bad game

Graph of the distance between the model and the workpiece based on the position on the profile