Actualités

New range of sorting machines QMTInspect

Enter Industry 4.0 era with area QMTInspect

Every year, customers are still more likely to trust the Qualimatest products. For 10 years, they hear and benefit from the expertise of a reliable and recognized leader in the field of automated sorting that is based on strong partner skills.

Why launch a new series of sorting machines, after the success of the encounter at present?

QMTInspect current machines are recognized for their reliability, ruggedness, and mastery of 0 standard. They are leaders in their market for 10 years. Every day more than 60 customers to ensure their contractors in a safe delivery.

Now the mission Qualimatest is to achieve perfection and more customers are increasingly mastering the default is 0. fulfill This new series of sorting machine is more efficient to meet the expectations of the market: this equipment strategic investment for companies become that satisfy their customers permanently want. This area is the customer by acquiring motivated objective standard equipment or customized products in Qualimatest program "Fit For You" .

Why QMTInspect range is superior and revolutionary?

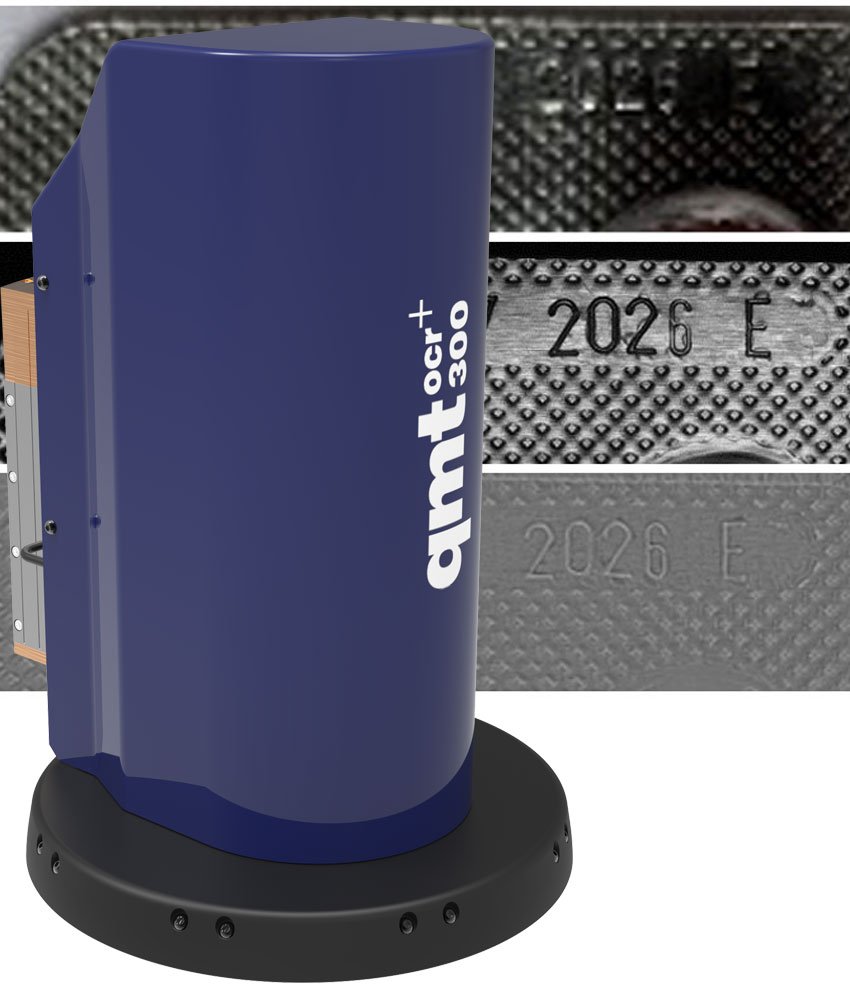

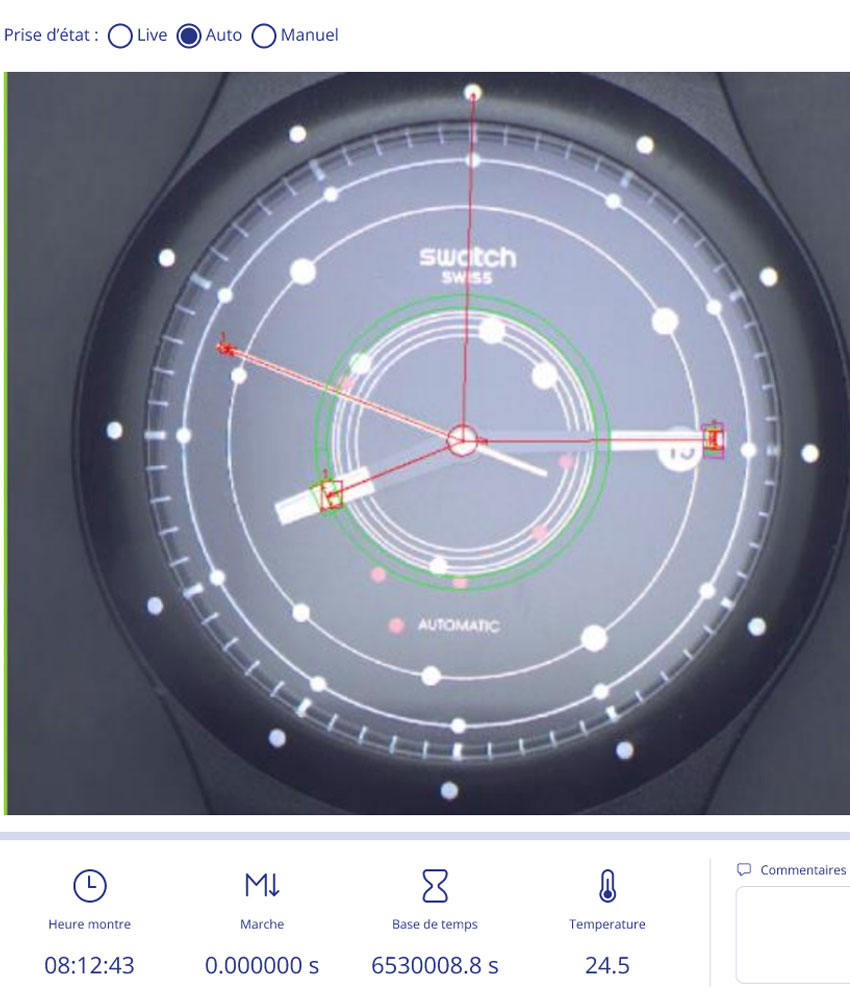

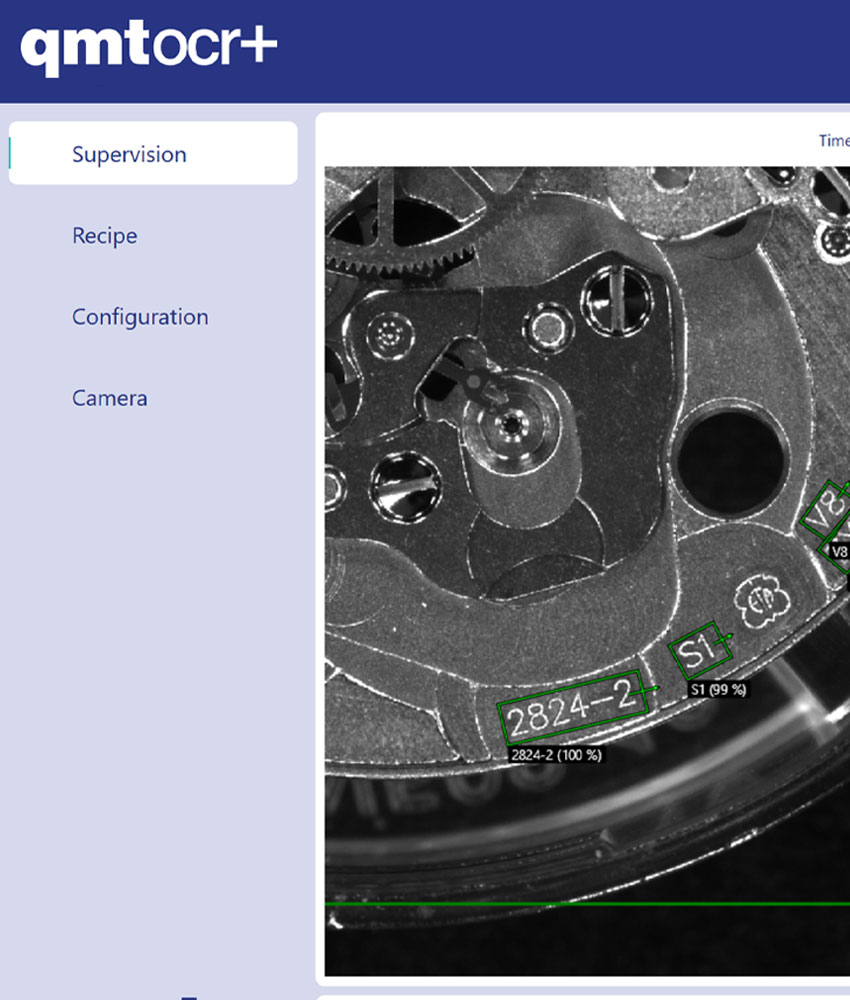

- The precise optical measurements with the news of improved QMT Vision - Inspector

- Automatic control of the sound and vibration response products QMTSound enables varieties that were previously impossible (operation of joints, cracked parts, ...)

- The control aspect is robust and efficient with QMTSubFace

- The sorting speed is increased by 20%

- New ergonomics and programming offer easy operation and a safe investment with the flexibility and scalability

- QMTSixSigma revolutionized the process improvement with the analysis results of a sort

- The individualisation program Fit For You perfectly meets the needs of customers

Of course, the force remains No. 1 Qualimatest service and customer care in the project, commissioning and operation of the machine

Two lines of standard equipment in the field

In order to meet different requirements, the range includes two lines machines

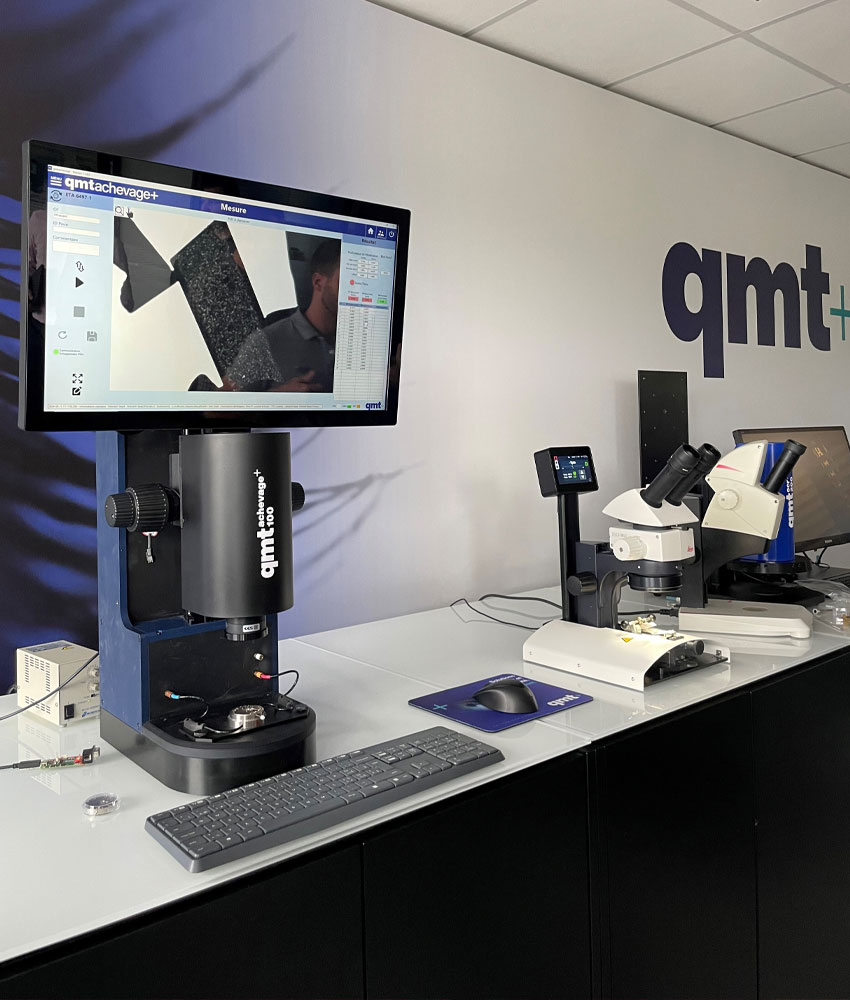

QMTInspect-100

This line is based on a circular workflow or glass plate (QMTInspect-110) or shelf with WCS (QMTInspect-120).

This line is a stable or unstable parts, size 0.5 mm to 50 mm. The sorting speed is fast, up to 36,000 parts / h.

Most current systems are now integrated to deliver the bowl feeder for greater versatility of applications flexibly.

The set of measurement techniques are available: Vision, by pneumatic buffer, actions will be supplemented by the contact, laser measurements, eddy current testing and new technologies QMTSound (control sound and vibration response products)

The workflow of this line is particularly suitable for aesthetic control of parts with QMTSubFace

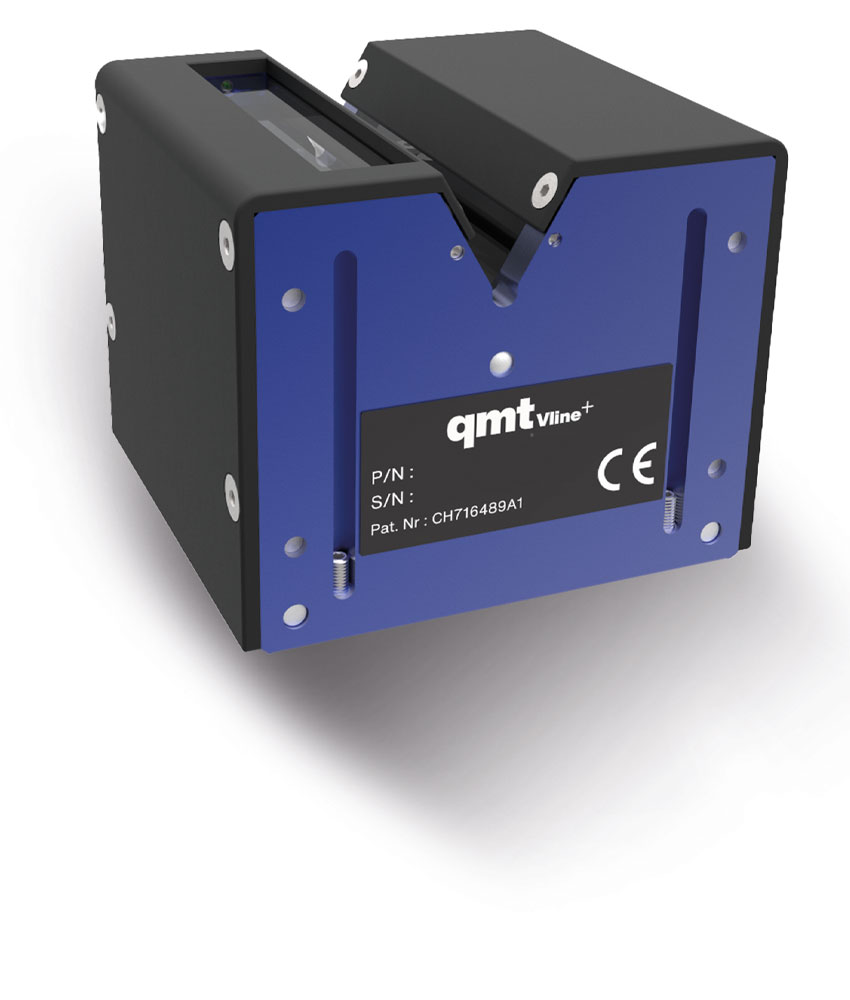

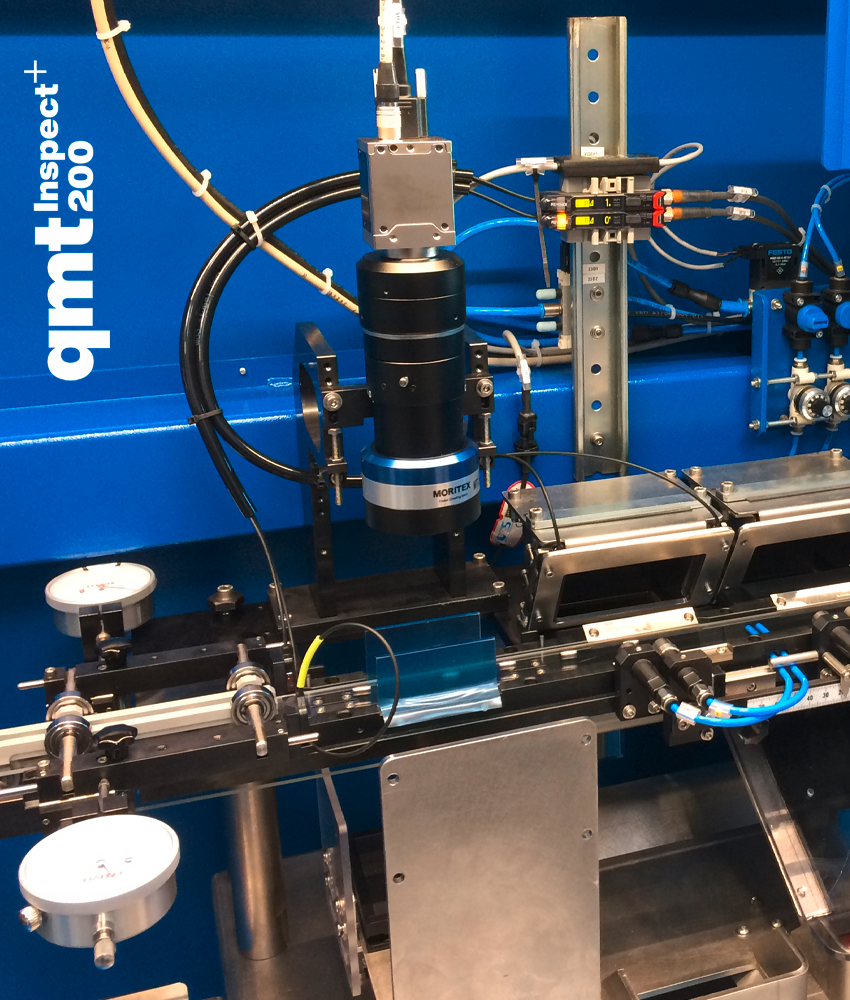

QMTInspect-200

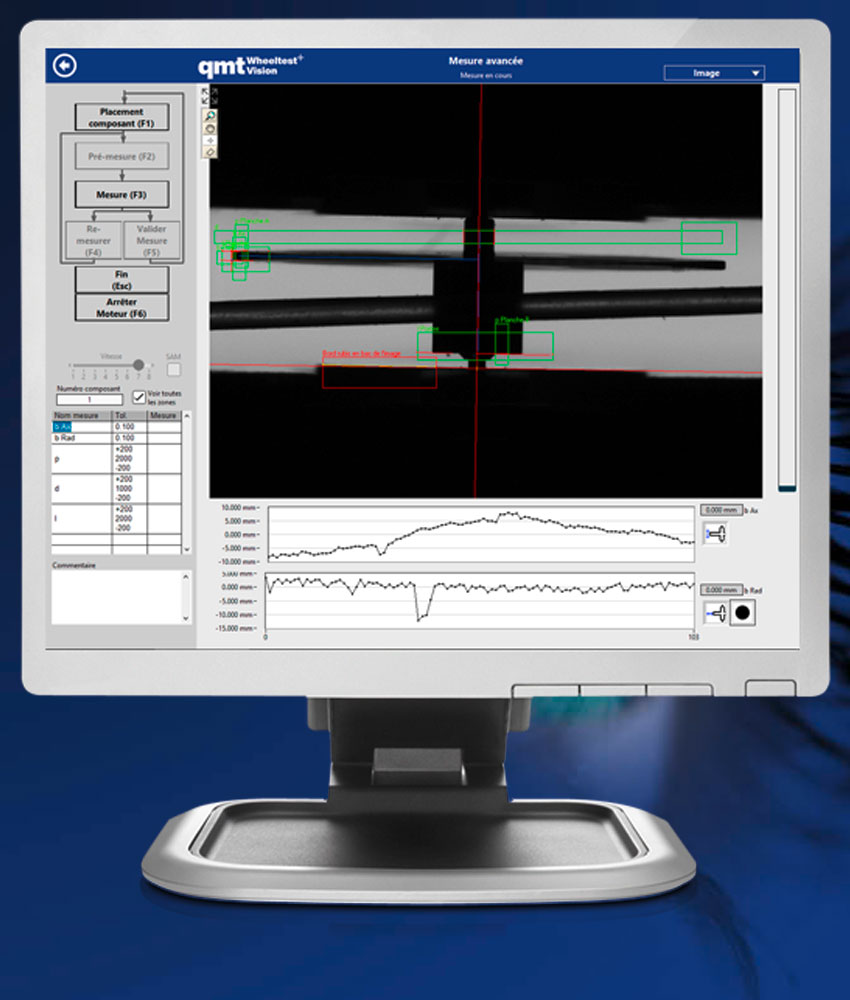

This line will be carried out based on a linear workflow through conveyor and controls by cameras.

It is the third generation of the Carrier, the latest version was to offer a combination of technologies developed from scratch, which allows for increased sorting rate of 20%. The new design offers better ergonomics and compactness. In the heart of the machine, the energy system is now isolated from control stations Vibration, enemies of precision, are controlled.

The workflow of the room has been completely designed and simplified re-control the position of the pieces during the entire movement. It is thus possible to have associated control systems with multiple ejections for accurate and efficient sorting multiple stations.

The following options are available for the control (multiple cameras at different angles), loading and unloading.

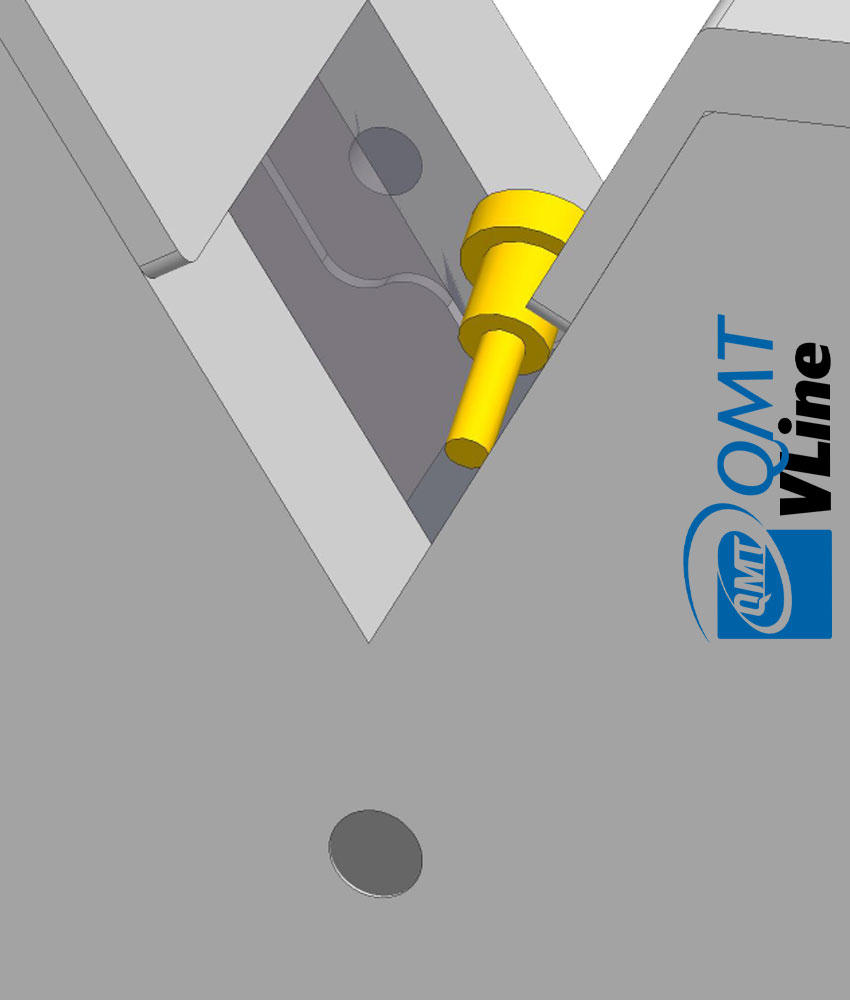

Special machines Fit For You

Search for customer specific solutions tailored to their own needs, Qualimatest engineers is supported by its partners proposed innovative solutions, robust and efficient with the program Fit For You