Réalisations

A producer of watchmaking cogs

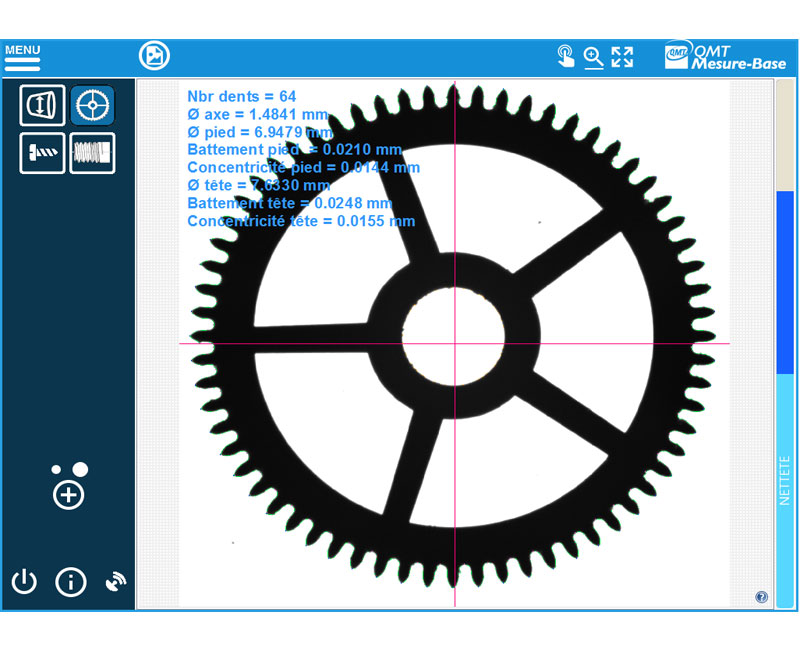

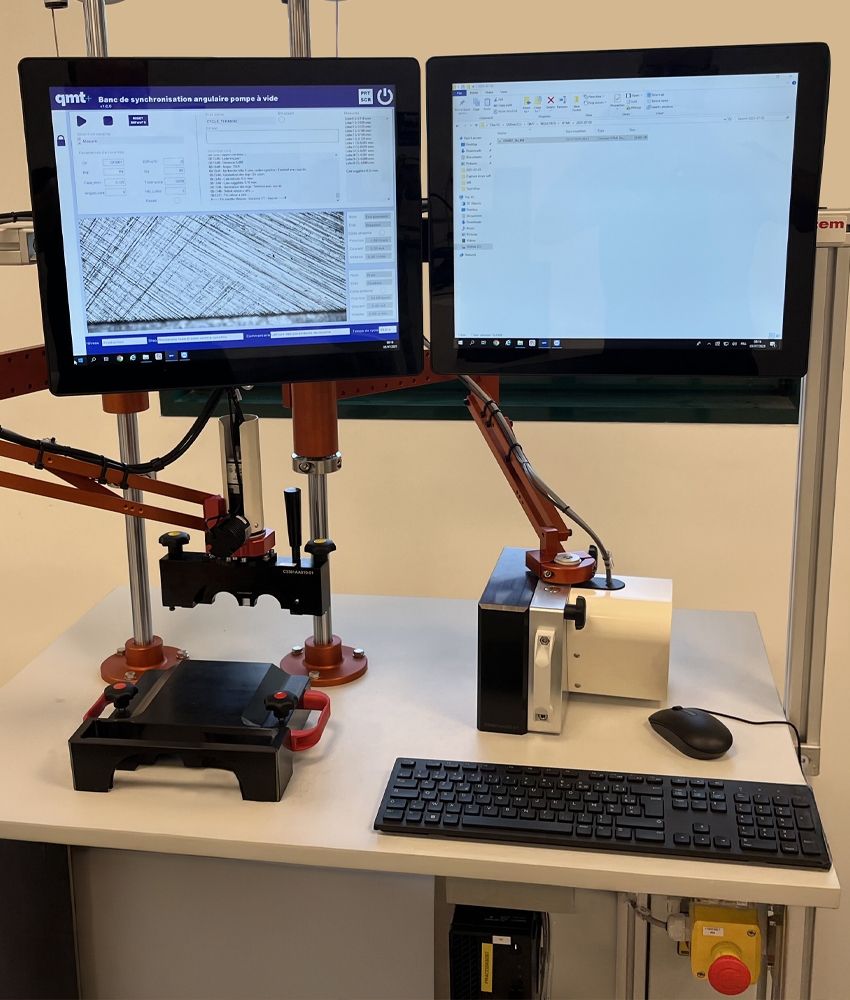

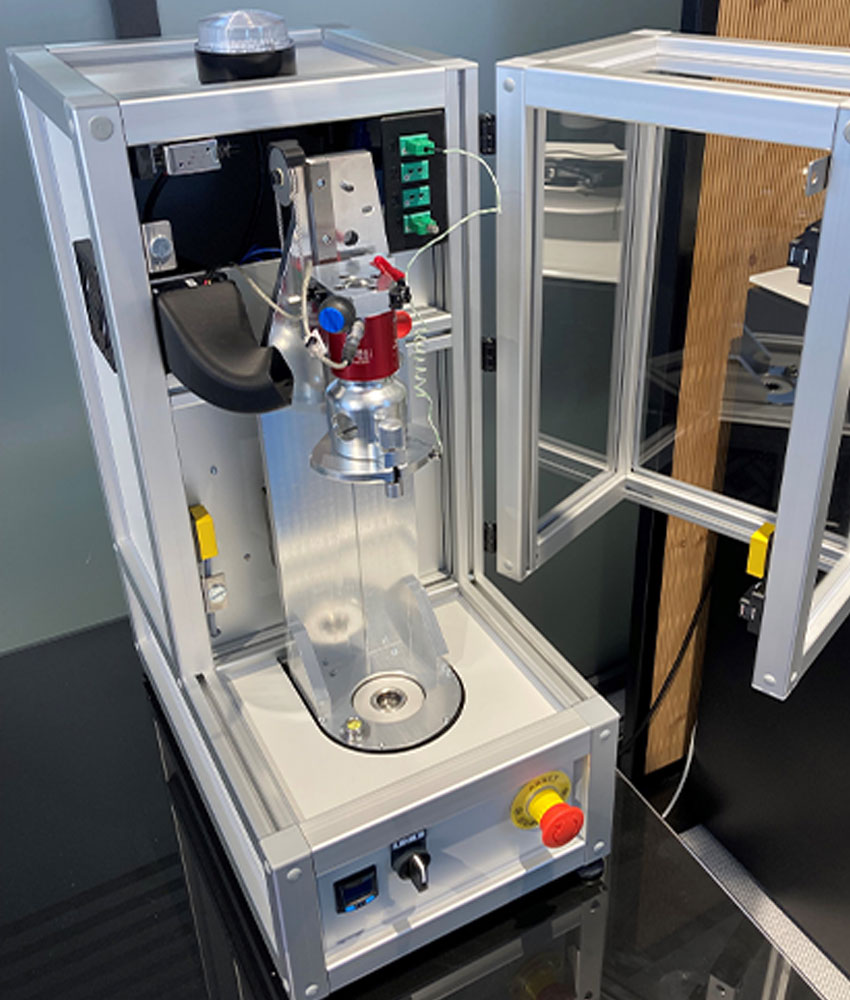

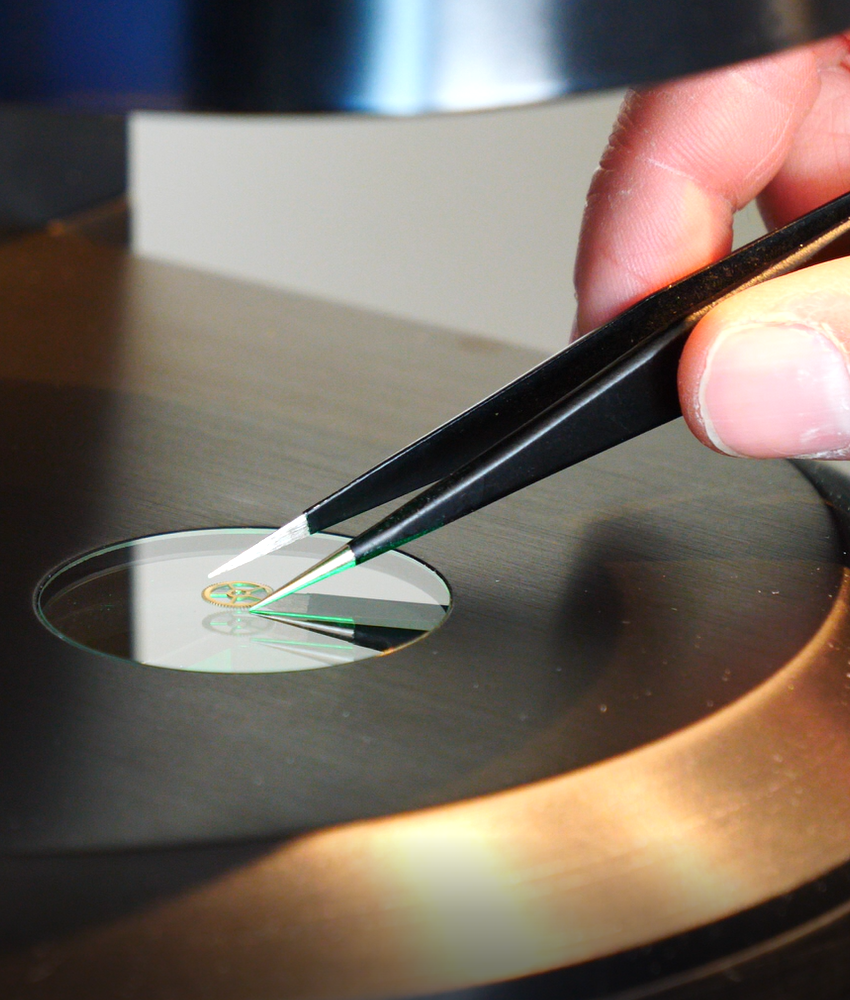

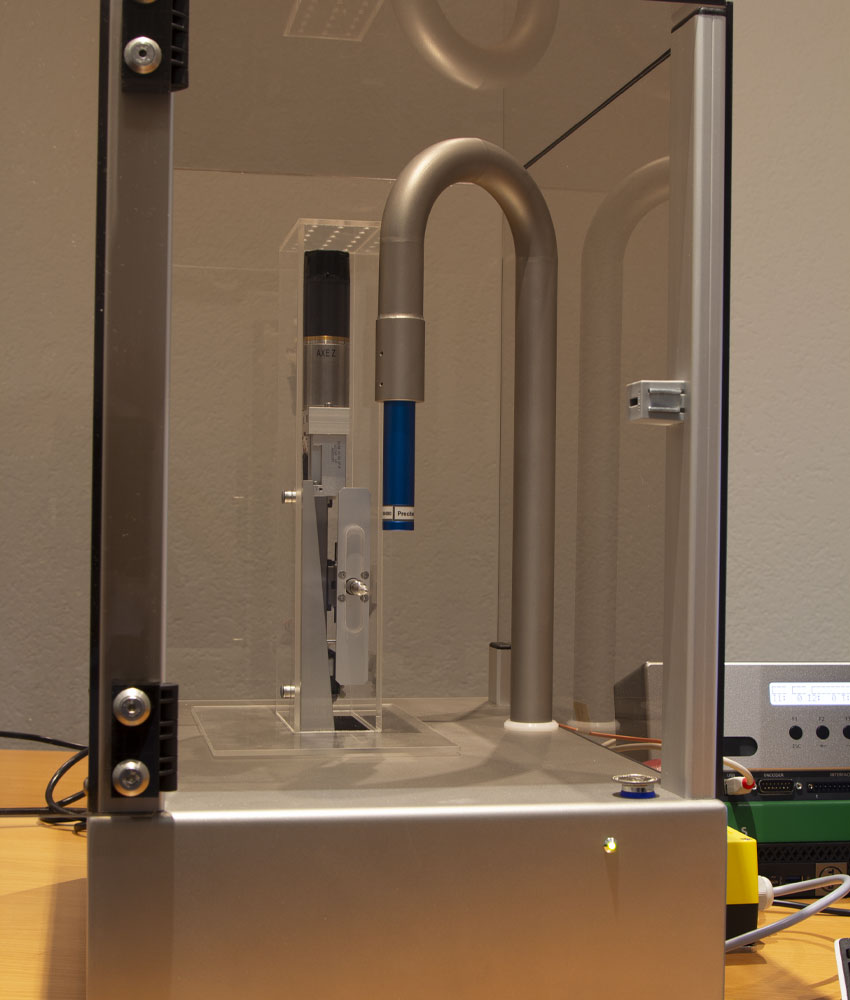

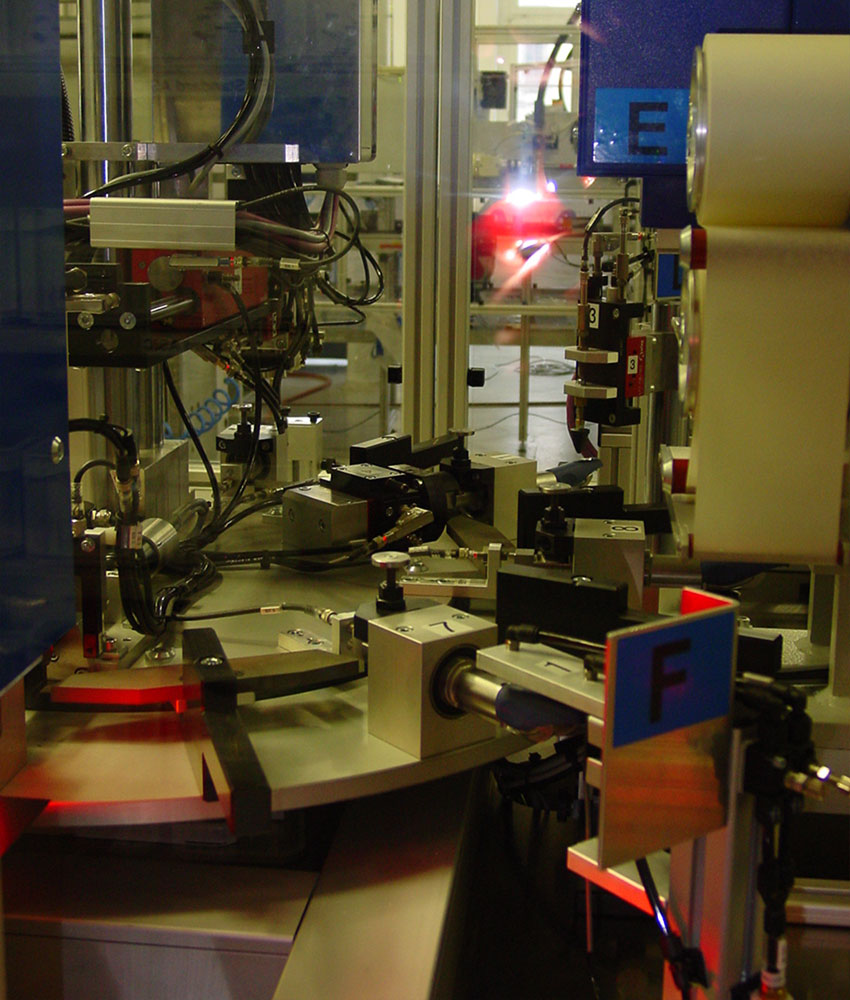

A big name in watchmaking in Switzerland specializing in wheel cutting has chosen Qualimatest and its QMTProjector-100 control equipment. This high precision measuring equipment is perfectly suited for use in a workshop.

Use Demonstration Film

Performance, simplicity and speed

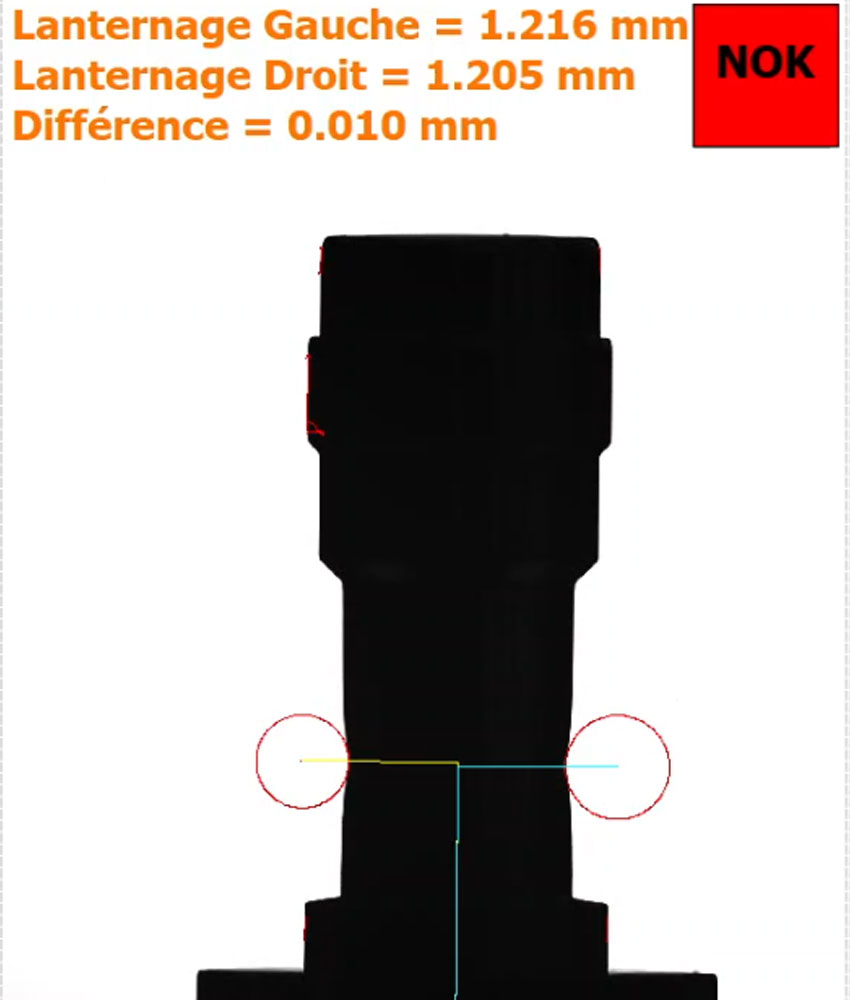

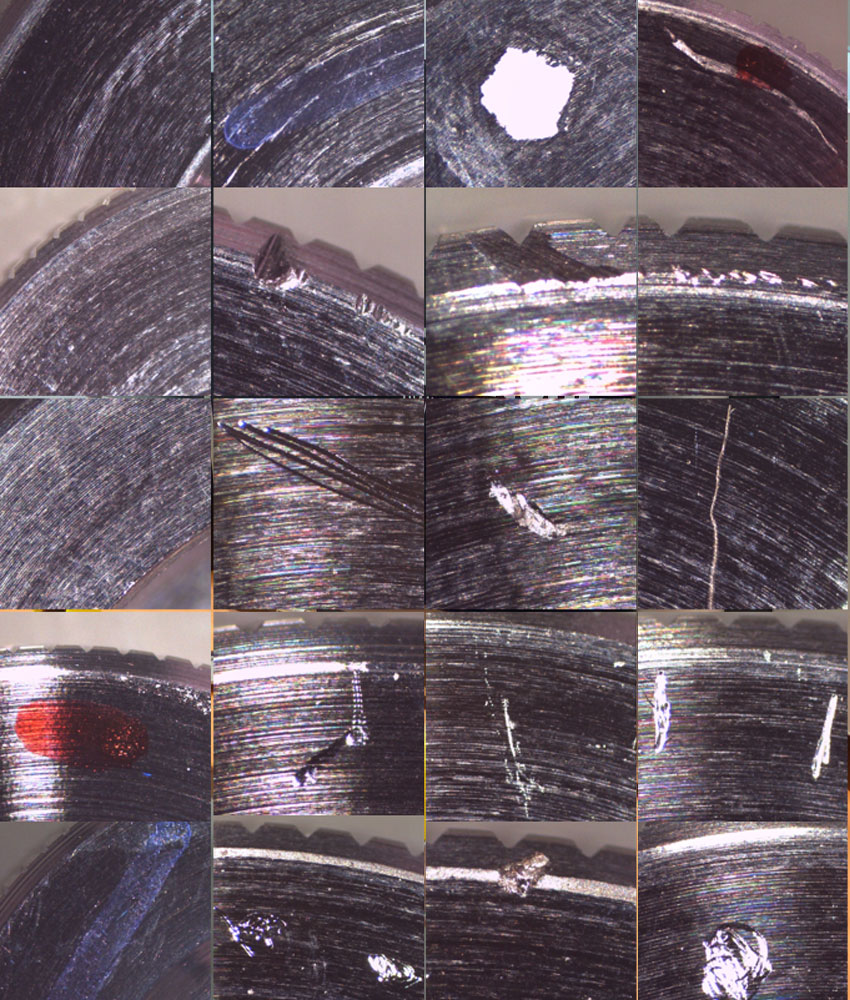

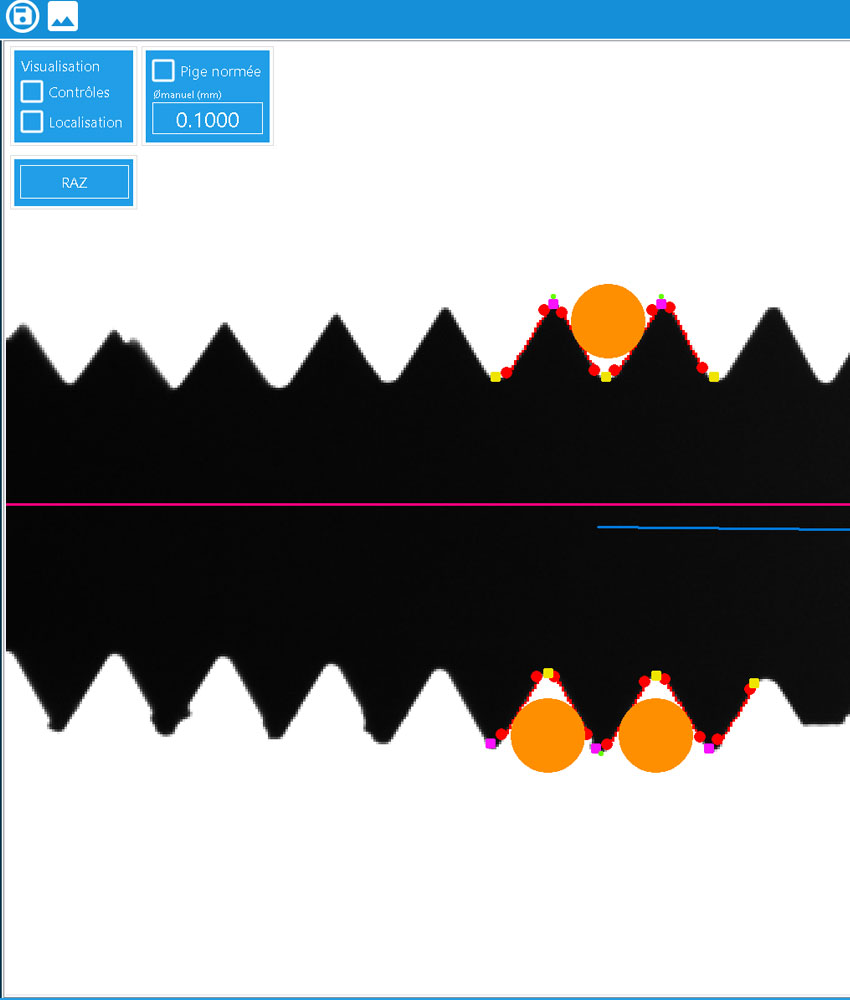

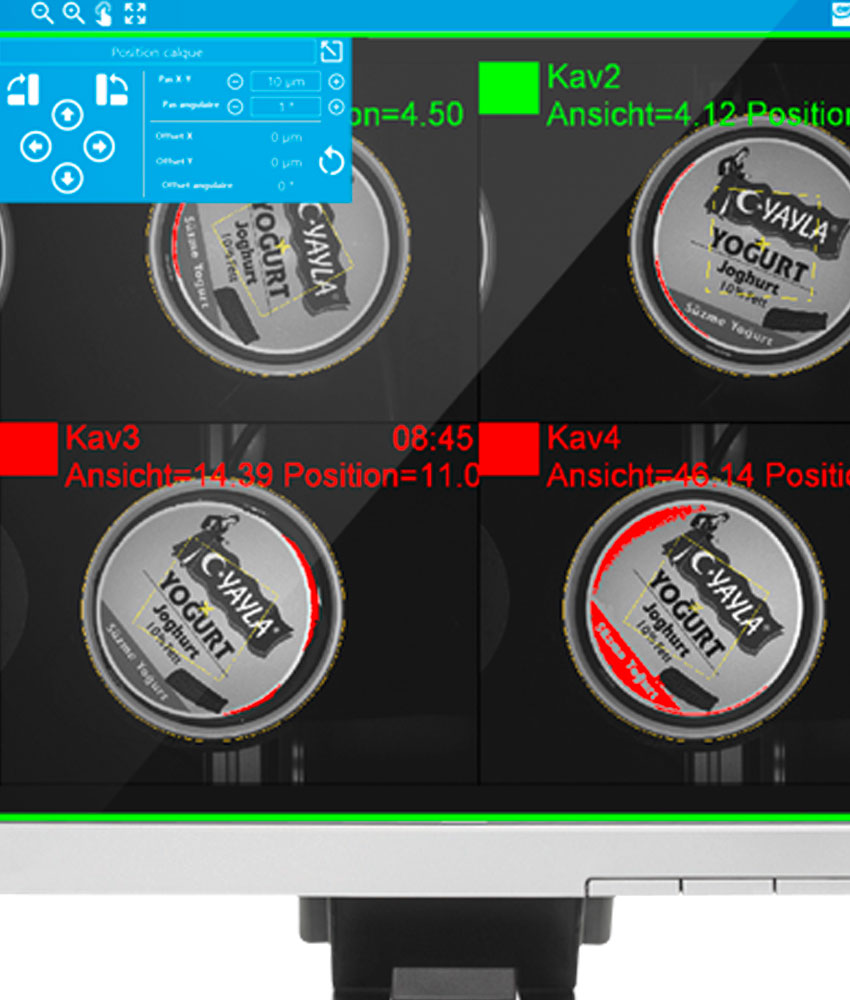

Automatic measurement of boards. All the characteristics (diameters, concentricity, runout, ...) are automatically measured on all types of boards

Control speed allows batch sorting

Movie playbackRobust in design, this device is equipped with an integrated computer. It benefits from the QMTMesure-Base software for high precision dimensional measurement (without any programming). High precision and ease of use are the two strengths that the customer has retained.

Although QMTMesure-Base offers, as standard, a large number of classic functions (length, diameter, etc.) and others with high added value (GPS function, threading, etc.), the customer wanted to take advantage of the program. F4U offered by Qualimatest. Thus, a new function specific to its measurement requirements.

Before integrating this equipment into production, the Quality department of this customer decided to launch a repeatability (R&R test) and accuracy campaign. QMTProjector exceeded customer expectations (R&R study according to MSA):

- Diameter of the central hole with IT of 6µm: R&R = 5% and Cmc = 19.8

- Concentricity with IT of 20µm: R&R = 15% and Cmc = 6.4

In addition to these special characteristics, QMTProjector-100 also measures all the parameters associated with watch wheels (number of teeth, flapping, etc.) as well as the measurement of the deviation from the DXF files of the parts.

Very intuitive and very fast, this new equipment was immediately accepted by the tailors, it has become today their favorite means of control.

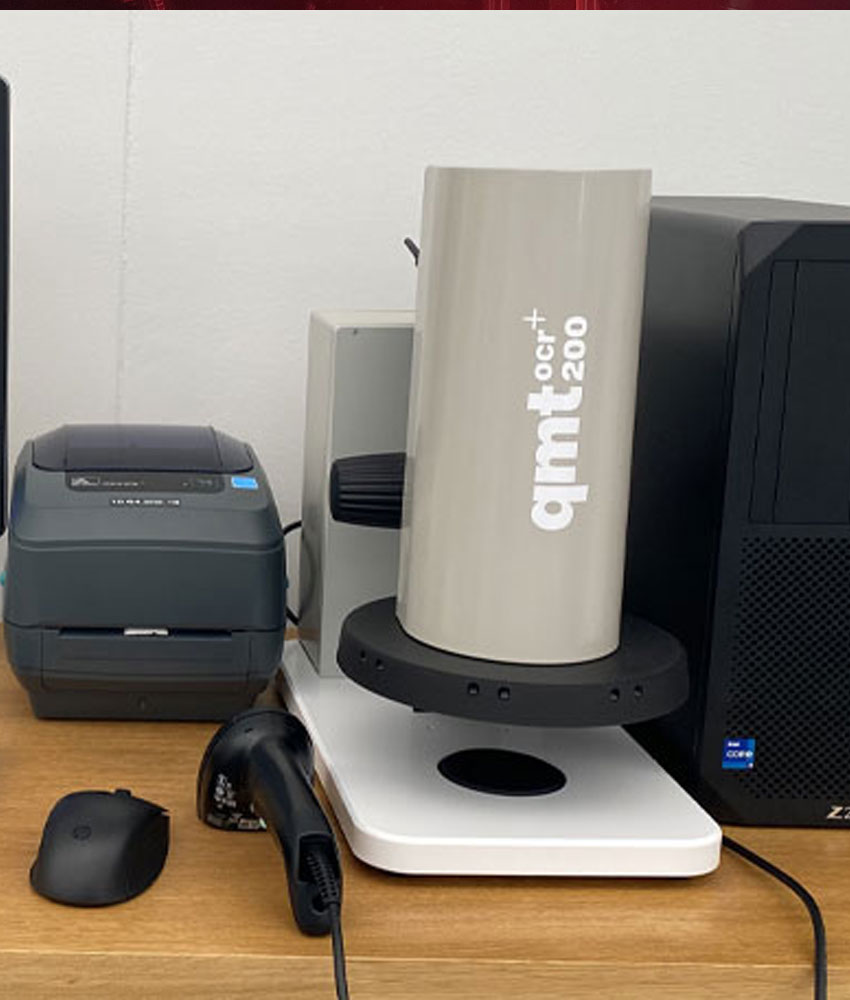

QMTProjector-100

High precision and compact equipment.

The QMTProjector-100 is a measuring device accessible to all and intended particularly for production control in the microtechnology sector.

More information