Témoignages

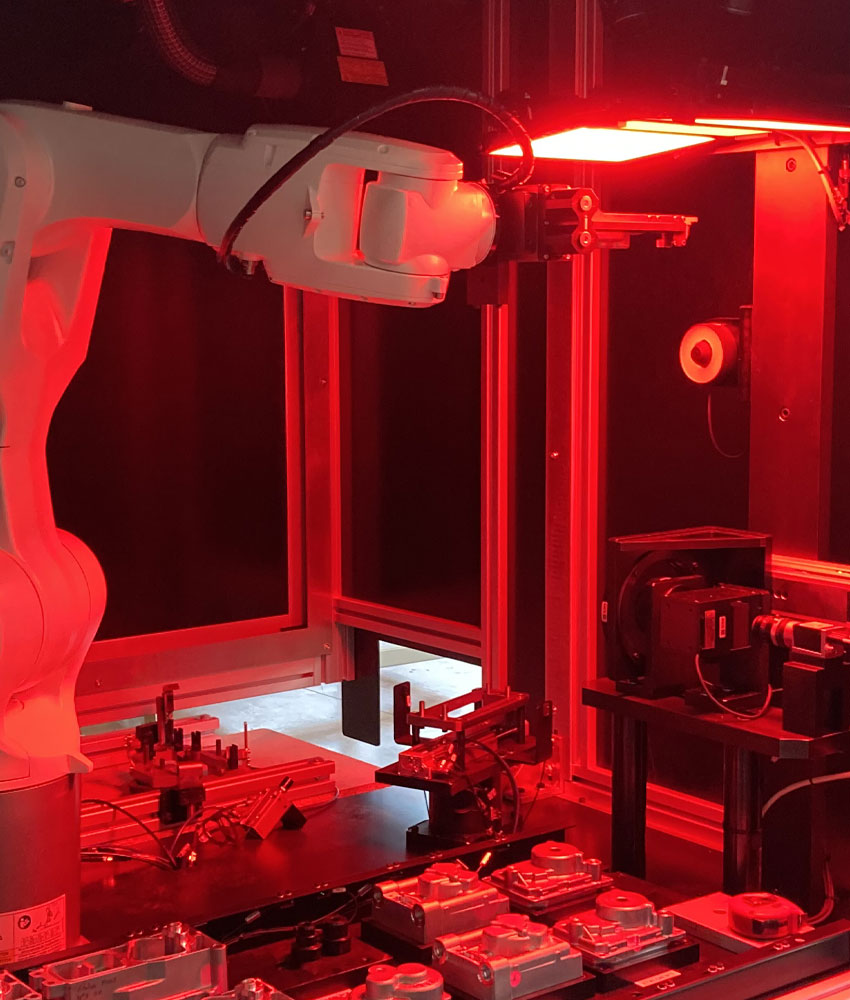

Railway contactor test bench for Sécheron

Advanced tests on all functional characteristics

In direct collaboration with Sécheron, a system for the acquisition and precision measurement of the electrical quantities associated with the contactor coil has been developed in order to guarantee the quality of the products delivered to customers.

Designed by qmt , the test bench controls and manages direct power supplies on “simple” coils but also on “advanced electronics” with very different current inrushes and responses.

Mastering all the trades necessary for the realization of a test bench (electronics, electrotechnics, instrumentation, IT, software, ...), qmt designed, developed, produced and put into service this test bench at the customer's premises . qmt also performs all the services to guarantee maintenance in operational conditions

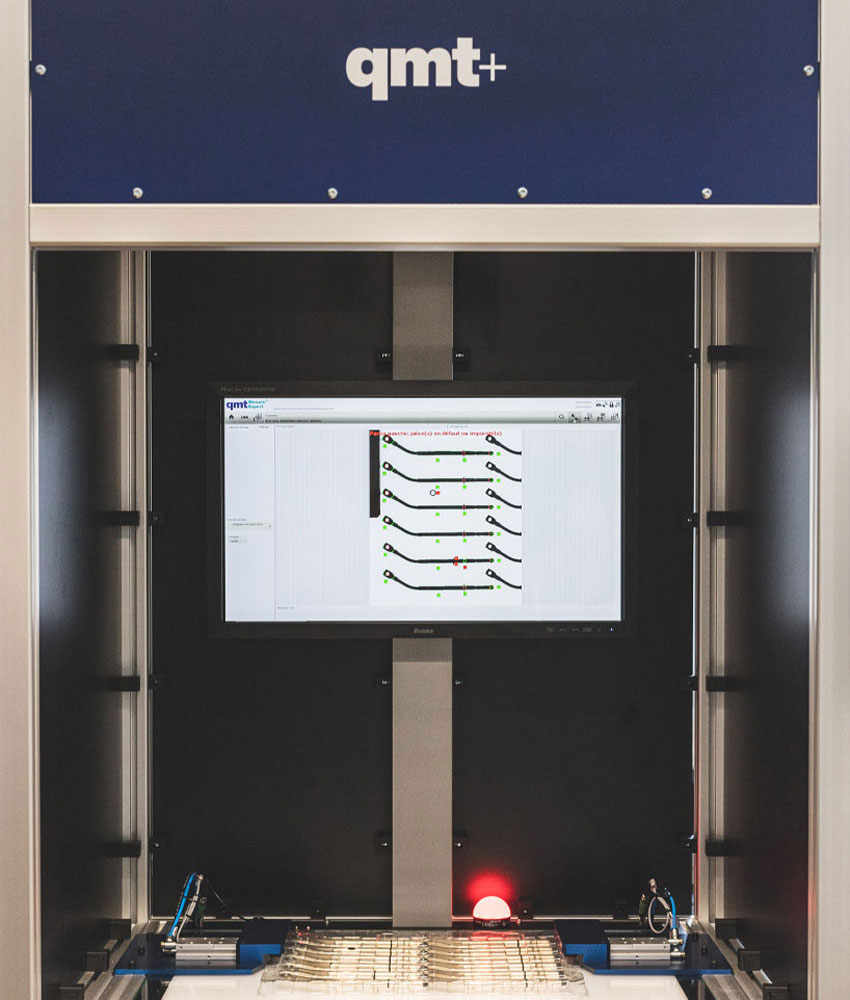

The measurements and controls carried out are:

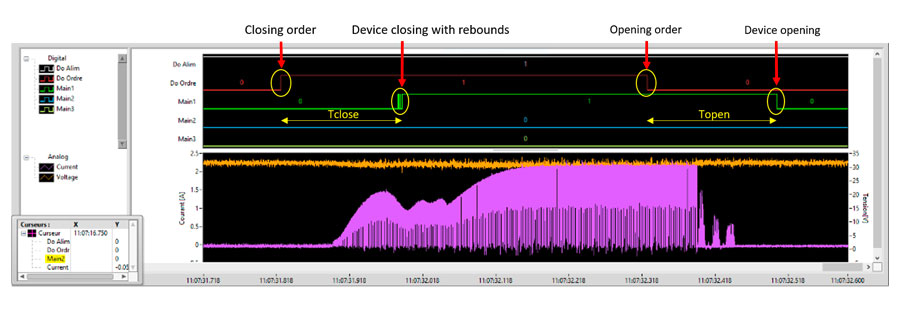

- Opening / closing operations

- Main contact resistance measurement (in µohms)

- Pilot coil impedance measurement

- Measurement of opening / closing times

- Checking the switching of the auxiliary contacts

- Measurement of consumed currents and power profiles

- Software interface with the global client sequencer (via the client network)

With very little operator manipulation, this equipment controls all of the physical quantities required for product validation.

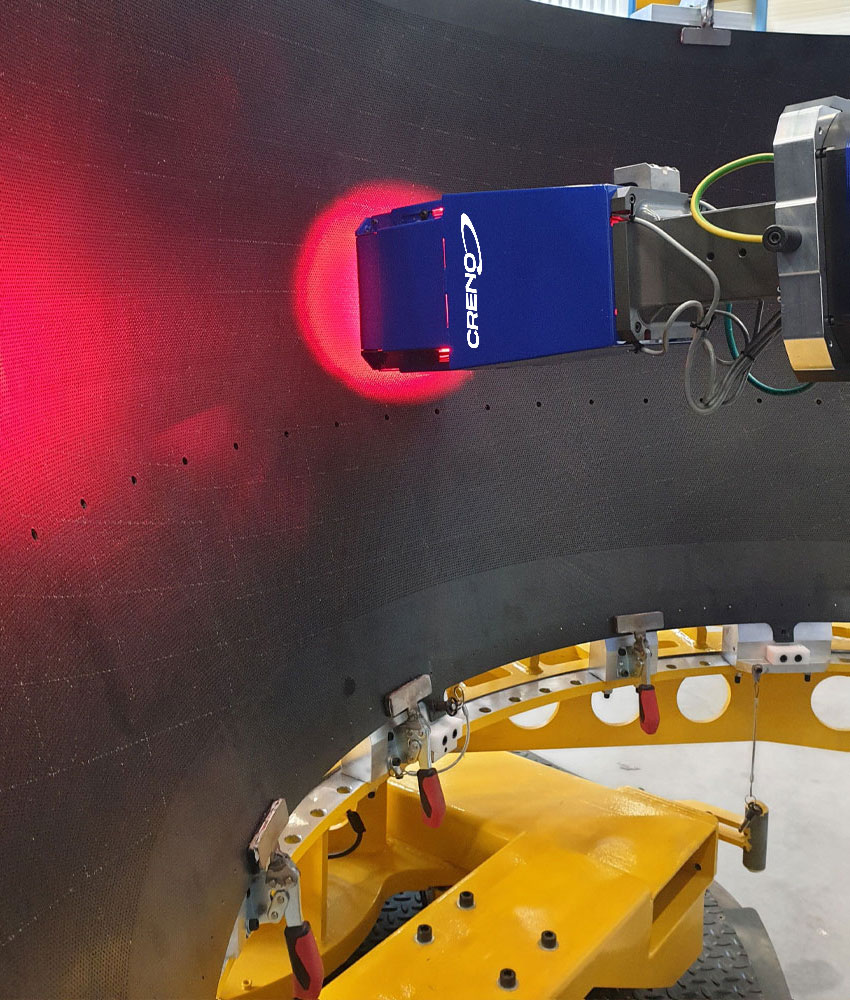

The main “challenge” associated with the development of such a bench is linked to the diversity of the products to be tested.

Indeed, the whole range includes products designed several decades ago but also very recent products at the cutting edge of technology.

Consequently, it is necessary to control and manage direct power supplies on “simple” coils but also on “advanced electronics” with very different current inrushes and responses.

In addition, a multitude of customer isolation schemes had to be taken into account and simulated. The implementation of a “matrixing” via specific high performance relays made it possible to understand all the piloting schemes.

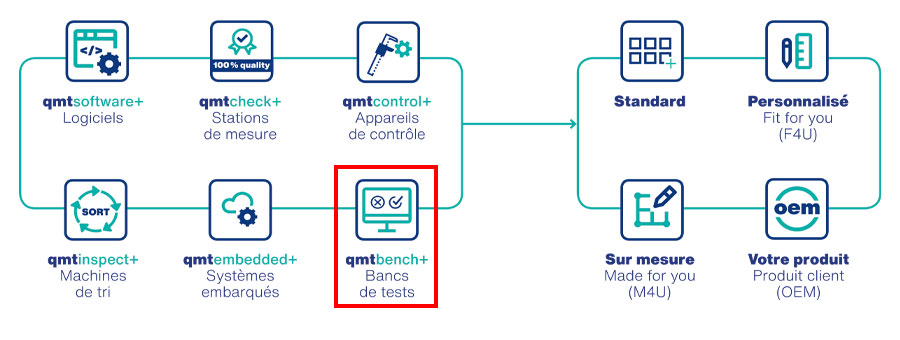

The experiences accumulated by qmt since 1989 have made it possible to pool common functionalities (“bricks”) for several types of benches and which can be reused on different projects. This standardization makes it possible to guarantee the quality and rapid manufacture of these “bricks”, at competitive costs. These functional “bricks” are an integral part of our qmtbench range.

The advantages of the proposed solution:

- A high test rate: a contactor is fully tested and validated in less than a minute

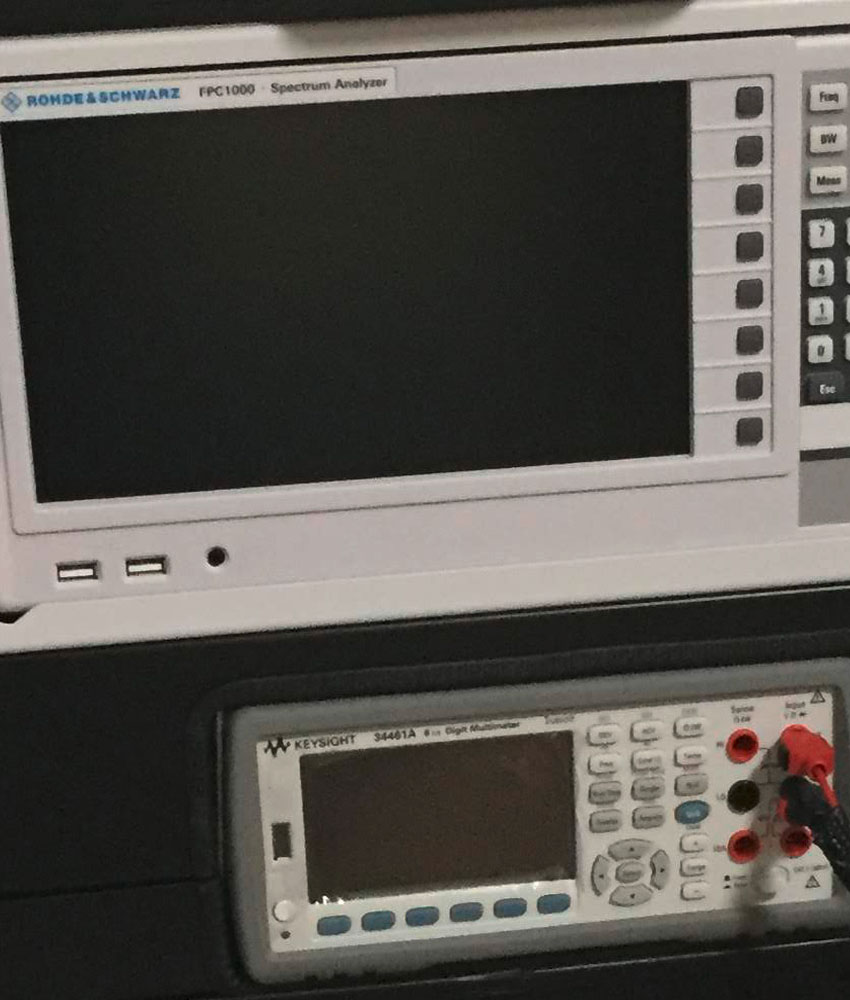

- High measurement accuracies of +/- 0.1% over the 0-300v / 0-30A @ 15KHz ranges

- Standard technological bricks guarantee the robustness of the solution

- Adaptability in the face of future developments or integrations at the customer's premises

Sécheron based in Satigny (Switzerland) designs, manufactures and markets contactors and circuit breakers at the cutting edge of innovation and installed for decades in vehicles around the world. Since 1879, the brand has been offering the essential expertise of exceptional manufacturing and quality.

The measurements allow the customer to validate the product against the production compliance template. Beyond the initial expectations of the customer, the bench gives the possibility of diagnosing in a preventive way failures on the control electronics. This preventive diagnosis is carried out by a detailed analysis of the shapes of the oscillograms, made possible thanks to the high sampling frequency and the measurement precision.

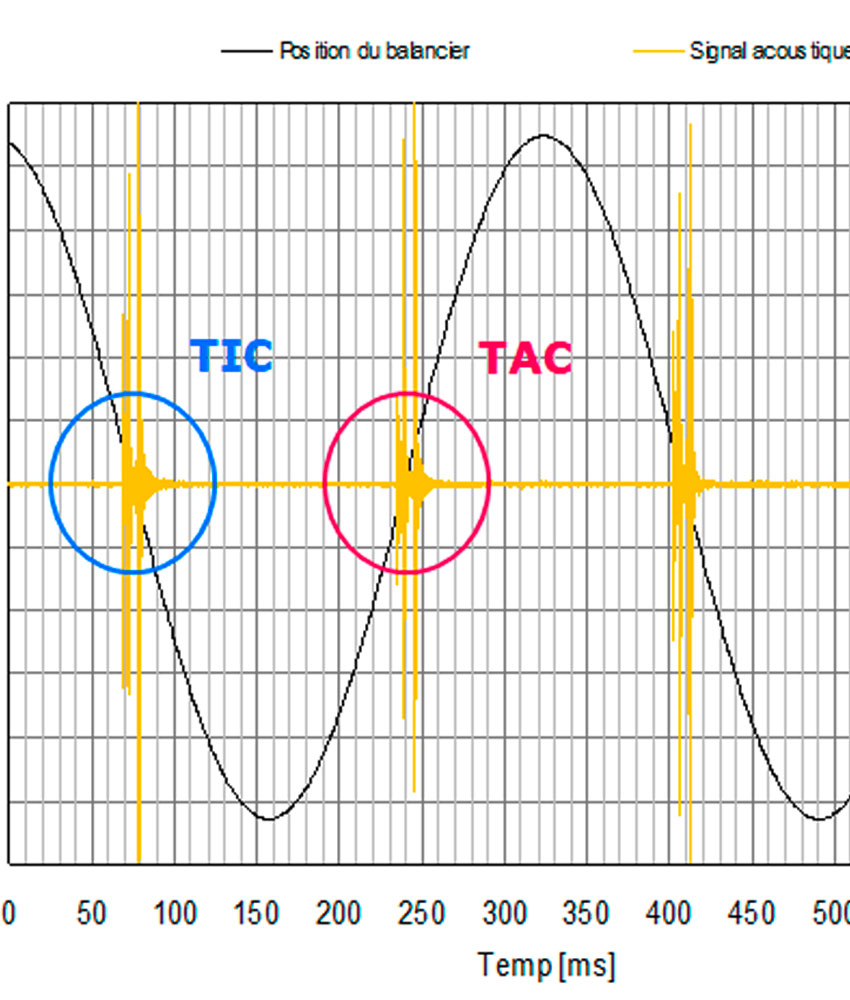

Measurement of electrical quantities at high sampling frequency:

From the design stage, discussions with the customer made it possible to set up, both in terms of hardware integration and software design, a “modular” architecture allowing the bench to be easily integrated into a “test set” more full. Thus, the bench developed is about to be integrated into a test chain where other quantities are tested. The surplus I / O on the measurement and control unit and the software bricks facilitated the integration of the qmt bench on the “global” customer test station.