Témoignages

Braking test bench for Safran Landing Systems

Renovation of the driving system

The “DAISY” brake test bench has been in service at Safran Landing Systems in Villeurbanne since 1996. It allows aeronautical and automobile brakes to be tested in different situations and the characteristics of the brake tested to be shown via a report.

The objective was to renovate a brake test bench comprising obsolete proprietary hardware and software for a durable and scalable solution offering a significant improvement in ergonomics and reliability.

Our solution was to adopt open and customized solutions enabled by the use of NI CompactRIO hardware and NI LabVIEW software, to replace obsolete components and improve usability.

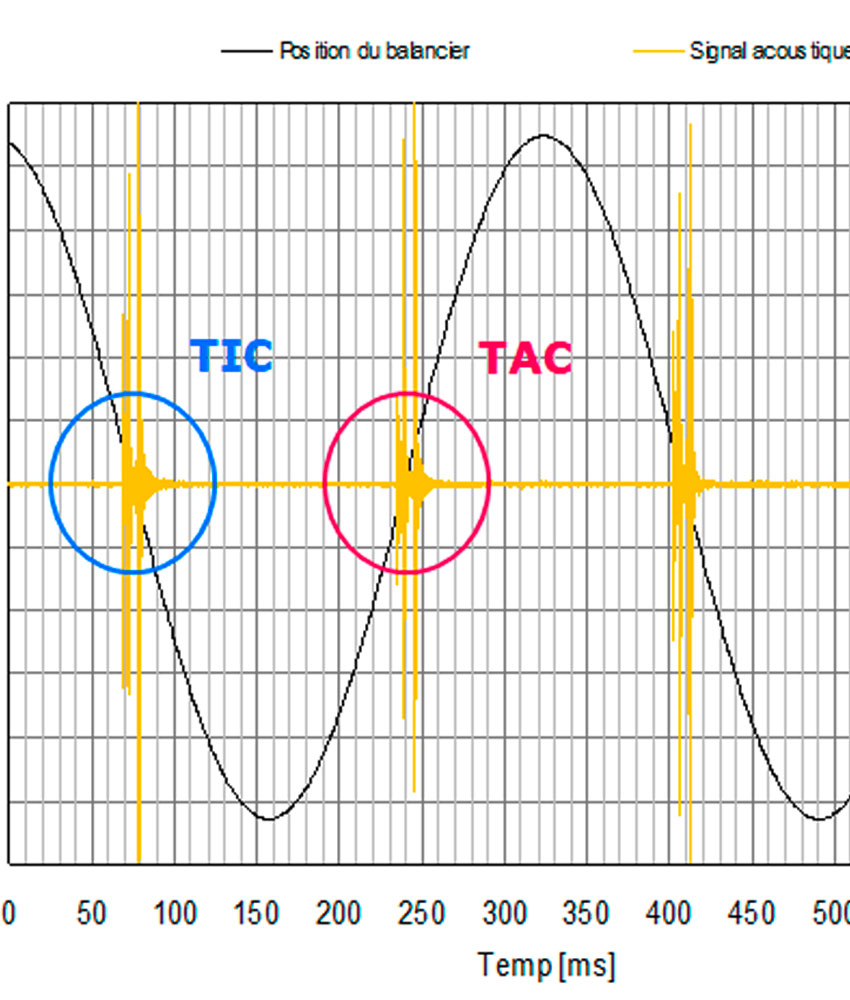

This test method must manage a large number of parameters. It controls the braking pressure or torque as well as the speed of the motor shaft to generate braking. A material inertia applied to the motor shaft using eight masses makes it possible to approach the desired inertia as closely as possible.

The compensation between the material inertia and the desired inertia is done by a simulation of inertia by intervening on the value of the additional torque supplied by the motor. As the tests must be as close as possible to the actual conditions of use, it is also necessary to check the air flow, the ambient temperature and the humidity.

Finally, a large number of measurement channels (temperatures, displacement of jacks, etc.) allows braking to be characterized as well as possible.

Certain equipment to be renovated and others not While the mechanics of the bench remain robust and relevant, its dilapidated control system presented high maintenance costs, too long intervention times and uncertainties of reliability.

It was necessary to deal with the obsolescence of certain equipment such as the VME control computer, the control PC equipped with its proprietary software, the specific brake regulator and the climatic ventilation management controller.

In addition, the operation of the bench suffered from poor ergonomics of the whole. It was complex to create test programs and impossible to import data. In addition, the display of data during the test was poor, and the records unusable as they were.

From a software point of view, it was necessary to keep the pre-existing functionalities, while improving them. The control interface had to authorize the piloting of the various components autonomously in manual or adjustment mode.

For the performance of the actual tests, the addition of an automatic mode was essential. The tests are launched from test sheets defining the braking cycles with the setting of the various operating conditions and the timing of the braking. The real-time display of the current values and the visualization of their evolution over time allows the test to be monitored precisely and quickly.

The real-time piloting of 1000 horses is complex and dangerous! Likewise, the pressure and torque must be regulated while ensuring the safety of the equipment under test and of the machine. The inertia simulation requires the direct action on the motor torque with a cycle time of 1 ms. The control of the brake (pressurization and activation) and of the torque respects a cycle time of 4 ms. Finally, it was necessary to acquire, process and store all the measurements at a frequency between 10 Hz and 500 Hz.

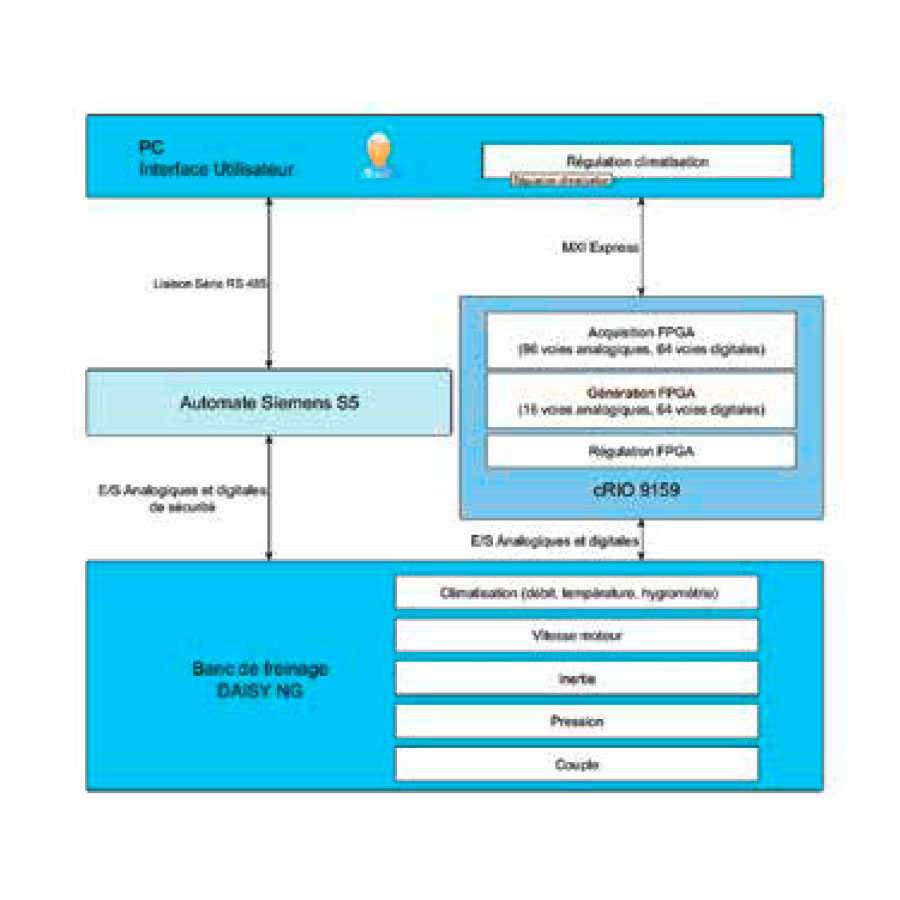

Two types of regulation are then mobilized: regulation on the control PC for air conditioning and regulation on board an FPGA (integrated in the RIO MXI-Express chassis) for rapidly changing critical parameters (speed ramps, pressure, torque) .

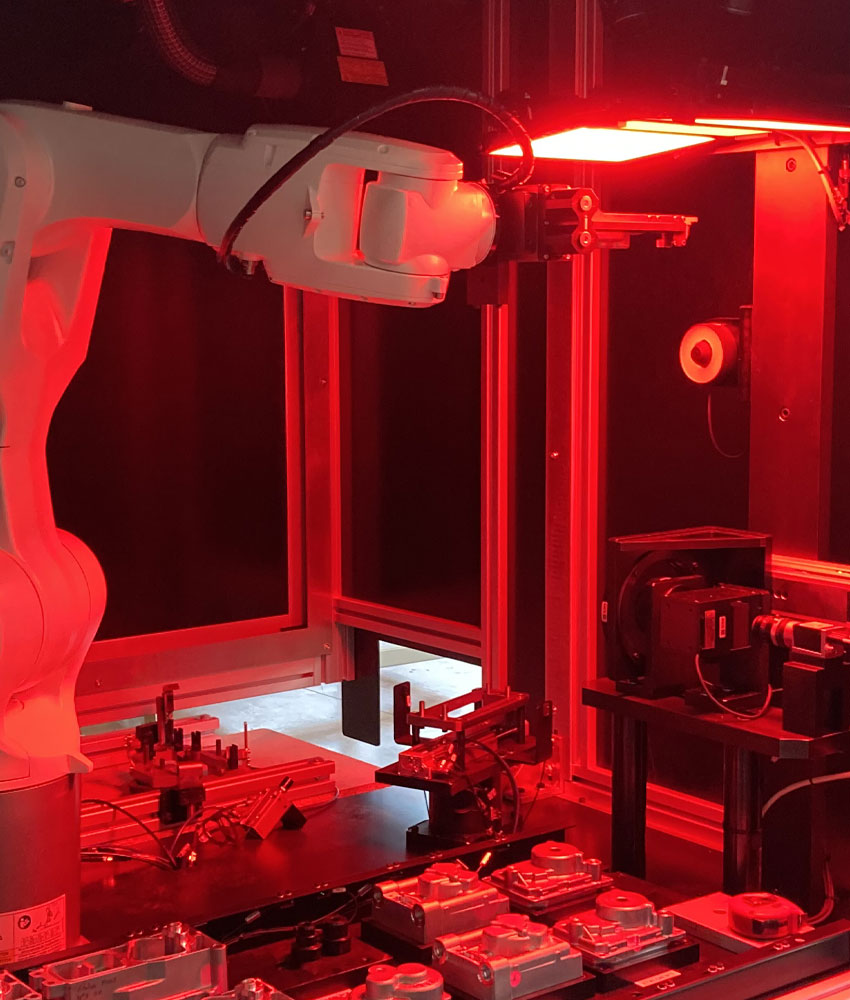

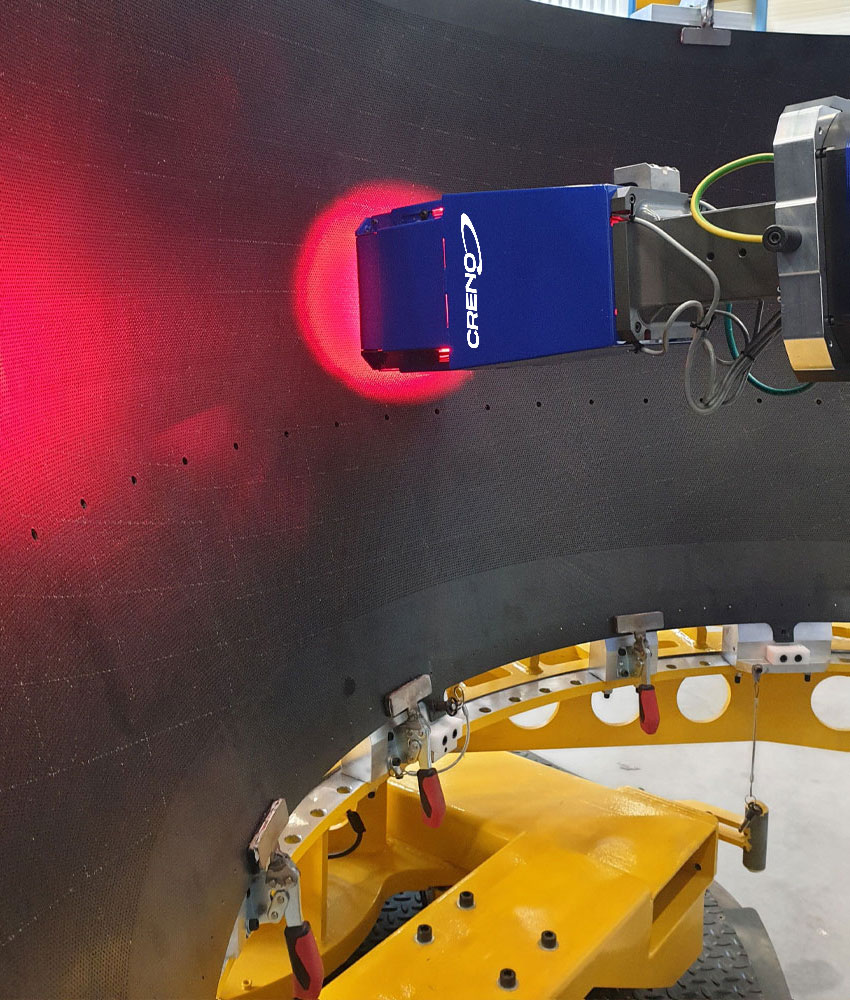

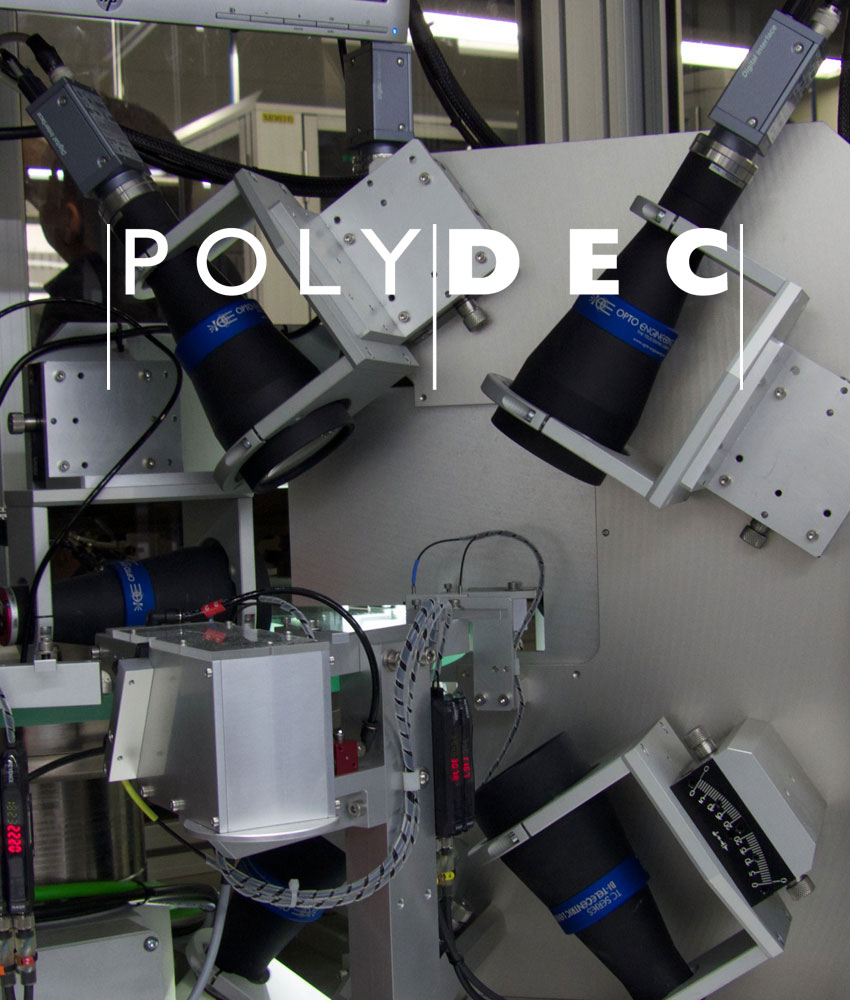

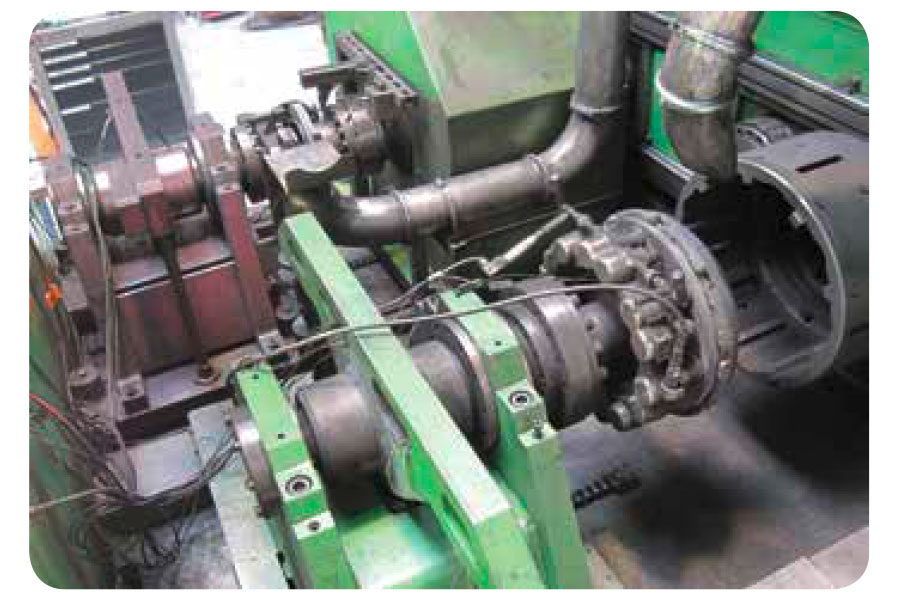

View of the two instrumented racing (Formula 1) and aeronautical braking stations:

High-level security is managed by the PC (monitoring threshold overruns) which can pause or stop the test. Low-level security (alerts, alarms) remains supported by a Siemens S5 PLC which manages certain types of shutdown. Communication between the PLC and the control PC is via an RS 485 serial link. The system can thus operate without risk for the equipment and the users.

To replace the previous system, which was bulky and has become unsuitable, the equipment chosen is based on an NI 9159 RIO expansion chassis and an MXI-Express card for communication with the control PC. Thanks to its 14 slots, the NI 9159 chassis allows you to wire all the inputs / outputs of the brake bench using:

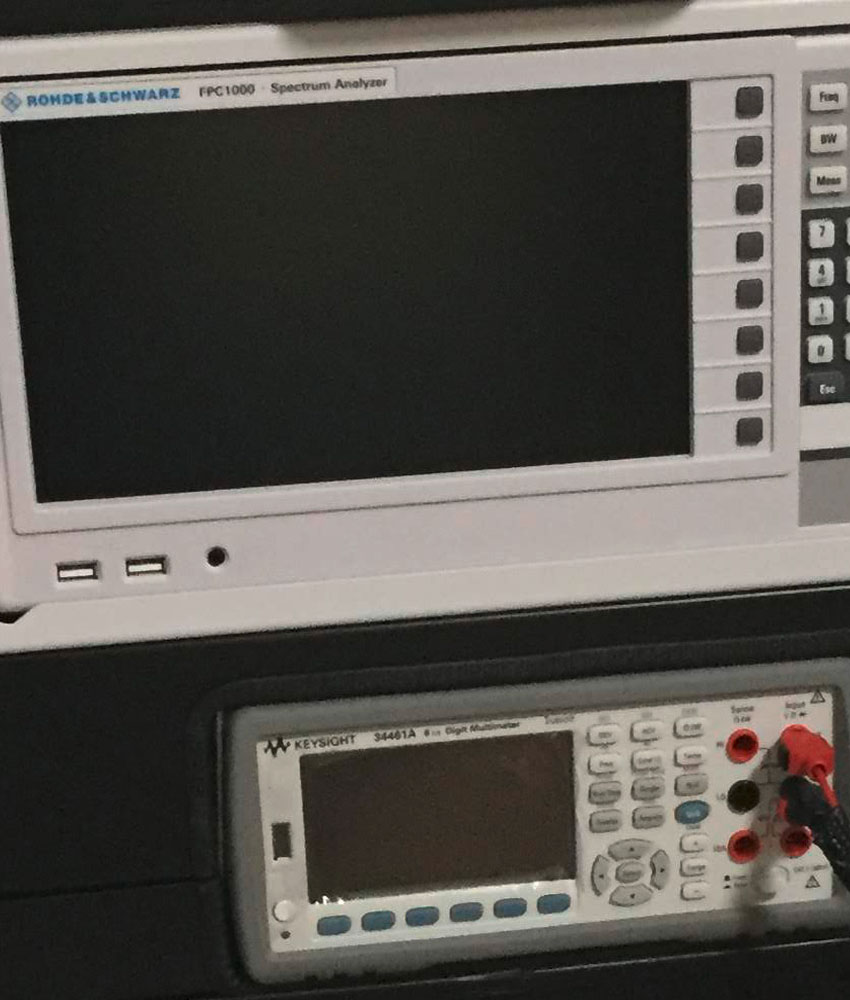

- two NI 9205 modules (64 analog inputs +/- 10 V) for speed, torque, pressure, temperature and other measurements

- two NI 9263 modules (8 outputs +/- 10 V in total) and two NI 9265 modules (8 0-20mA outputs in total) for the voltage or current control of motors and servo valves

- an NI 9426 module (32 digital inputs) for operating reports, alerts, faults and alarms

- an NI 9476 module (32 digital outputs) for controlling the operation of motors and servovalves, as well as air conditioning management.

Three slots remain available on the MXI-Express RIO chassis, allowing possible extensions.

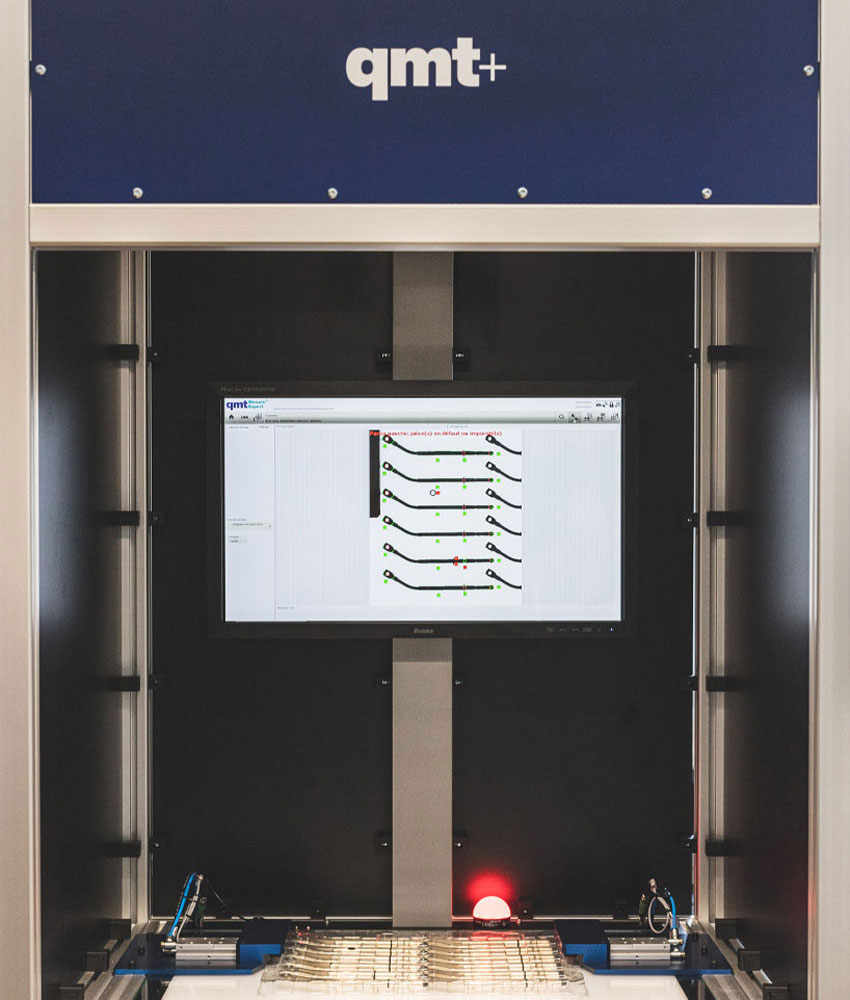

The handling of the bench is now considerably easier. Test management is based on Excel workbooks with three separate databases and a test procedure workbook. The databases provide access to material, specimen and test requests. The workbook is used to define the various tests carried out over time.

A macro automatically generates a "Test Sheet" containing all the necessary information. This "Test sheet" is interpreted by the control software after syntax check.

The main user interface panel makes it possible to follow in real time the curves and the displayed values, to suspend the scrolling, to zoom ... Thus, it is possible to visualize very quickly any possible anomaly related to a bad definition of the test protocol , which is essential to ensure, on the one hand, a correct use of the equipment, and on the other hand, the adequacy of the settings in relation to the demand.

The interface visualizes the progress of the test phases allowing the user to control the good progress of his tests.

The use of LabVIEW made it possible to quickly prototype the interfaces; their approval preceded the development of software modules adapted to operators' expectations.

This large-scale project required the alternation of substantial phases of conceptual analysis and validation; he demonstrated the importance of collaborative work between technicians, project manager of the company Safran Landing Systems and the development team of qmt . The result obtained makes it possible to calmly envisage continuing the braking tests.