Témoignages

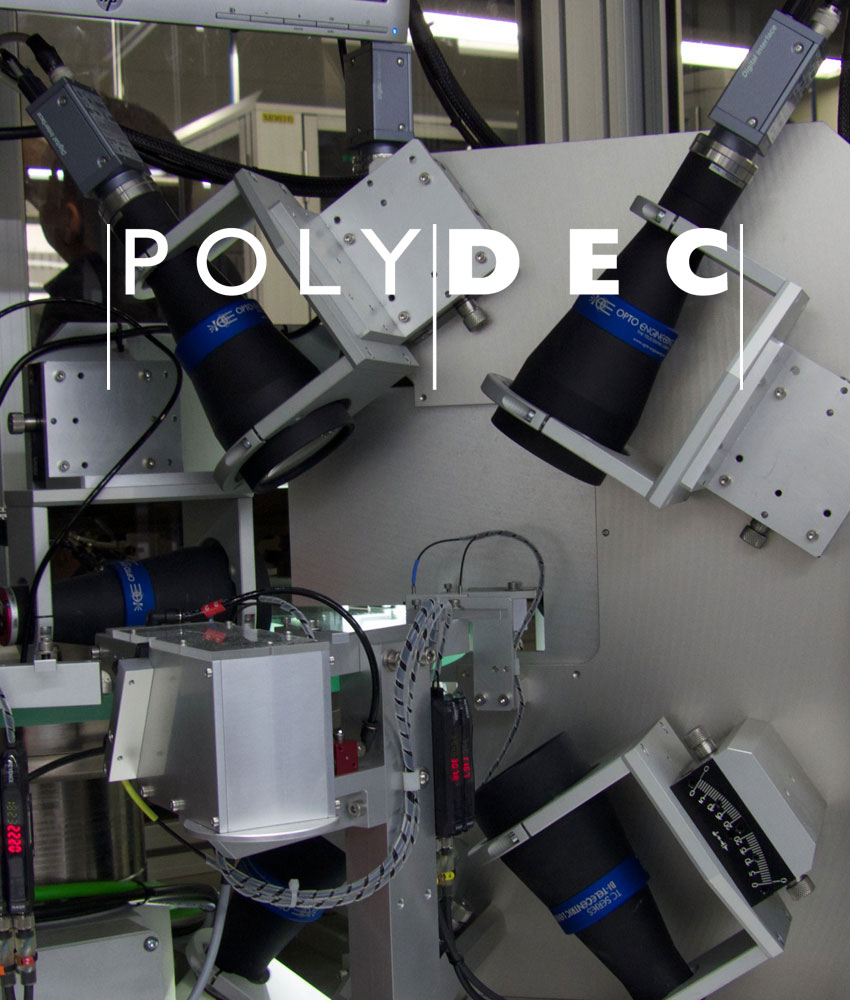

Measuring stations for sorting machines for Polydec

Located in the Jura Arc, a region that saw the birth of the Swiss precision bar turning industry (Europe), Polydec SA produces very small high precision turned parts, with a diameter of 0.05 to 4.00 mm and a length of maximum of 50 mm. Its customers come largely from the automotive, electronics, watchmaking and medical industries.

We produce tens of millions of parts per month for the automotive market. This market is particularly demanding, and we are also the first to wait for a car to run perfectly and for a long time.

At Polydec, it is clear that product quality is first and foremost guaranteed by mastery of the manufacturing process. It is perhaps worth remembering that the manufacture of a "simple" axis requires a significant number of operations which unfortunately add an additional risk of non-compliance at each step.

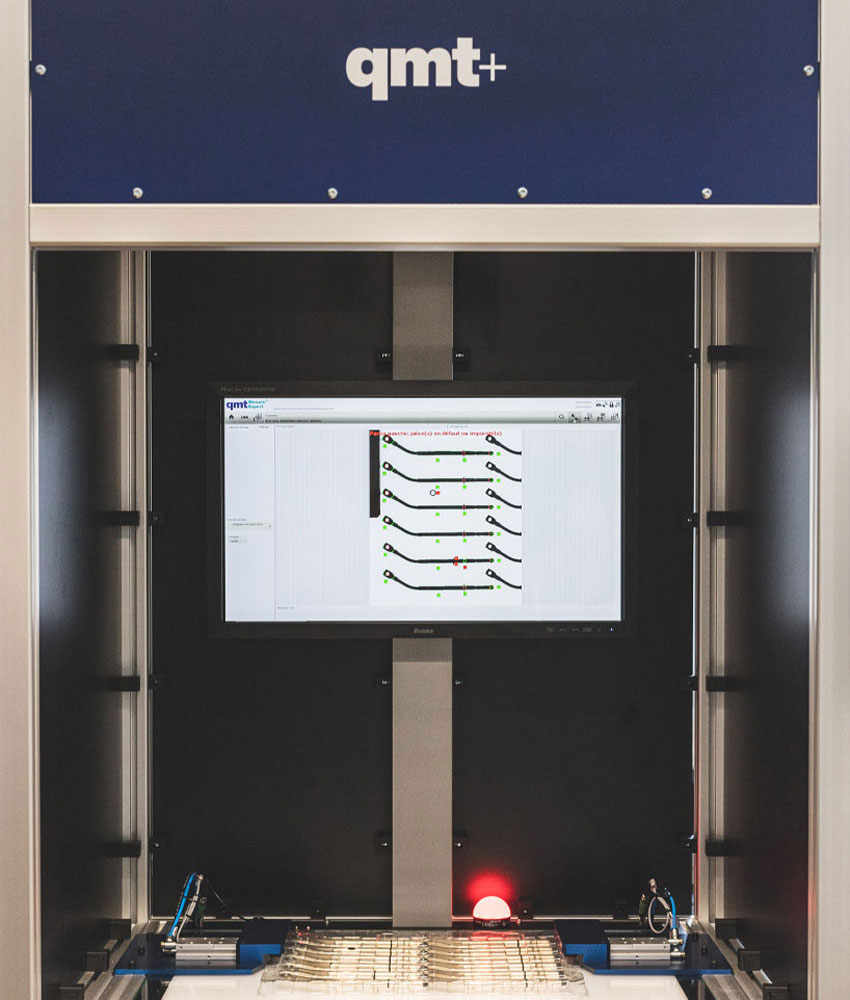

To satisfy our customers and protect ourselves from legitimate concerns, we have long been oriented towards 100% control by automatic machines. In fact, it is not a question of sorting the parts at the dimensional level (in the sense of putting them by product class), but of guaranteeing the elimination of foreign parts, bent parts or parts with other manufacturing defects. .

The rate of parts eliminated by these machines is indeed very low… but the elimination of these few parts is essential both for the satisfaction of our customers and for our risks as a supplier.

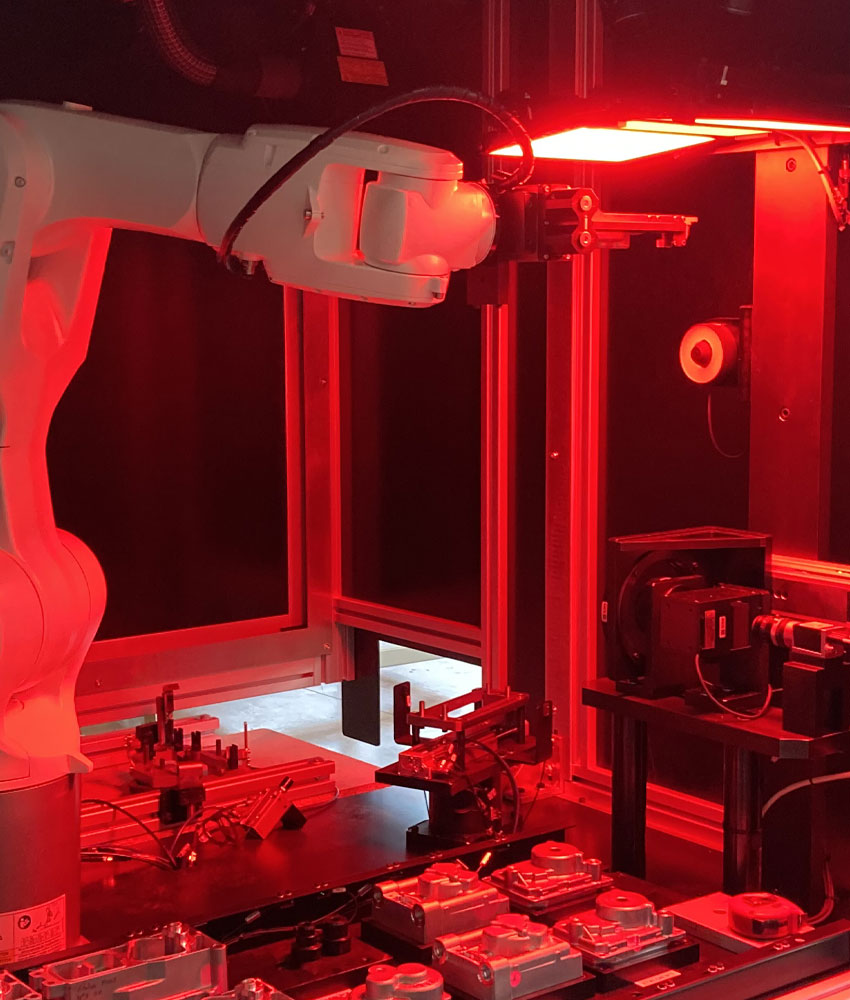

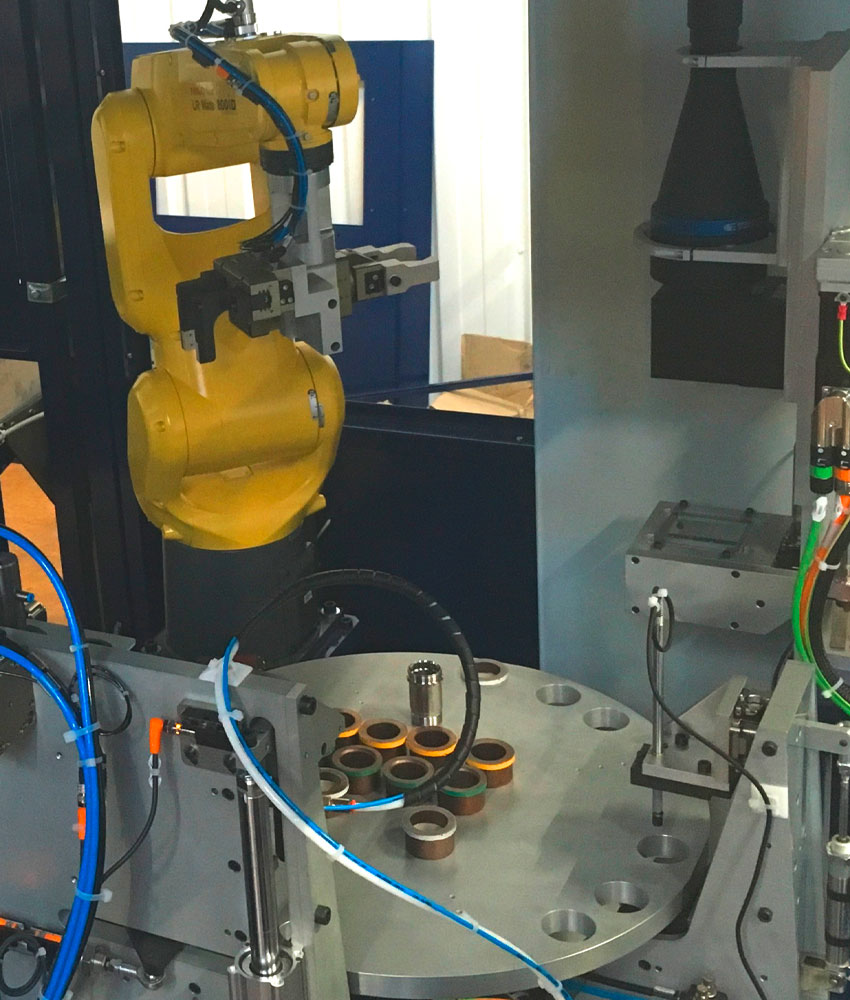

The machines we use are made on the basis of our specific needs by manufacturers of "special machines". In 2011, faced with the increase in the volumes of parts to be produced, we approached the Atec-Cyl house for the realization of a new automaton. Our need was clear on the principle of measurement, but we had no particular preference on the supplier of the vision part. It is therefore Atec-Cyl, strong of previous experiences, which proposed to us to collaborate with qmt .

The controller was therefore built at Atec-Cyl, then we were put in contact with qmt for the development phases of the vision programs, then for the approval of the machine. Obviously, qmt's support continues to be necessary, particularly in the event of changes to our products or additional needs linked to our continuous improvement. This fruitful collaboration is now taking place directly (therefore without going through Atec-Cyl).

In fact, the essence of all control is that it does not add value to the products: it is not because a product has been controlled that it is better than before!

What does change, however, is the guarantee of not letting a non-compliant product leave for our customers. The contracts that we must honor with our automotive customers leave us no margin of tolerance.

So the benefits we derive from these machines are measured by the almost zero rate of customer complaints and the reputation Polydec has built for itself in the field of automotive axles. Of course, all of this comes at a cost that inevitably affects the price of our products, but Polydec has always put quality first.

As said, the relationship was established little by little, first in a commercial phase, then during the establishment of the specifications. This relationship then evolved a lot, and today we maintain regular contact with the technicians. Over time, we get to know each other better and dialogue is much easier. In addition, being in contact with a French-speaking house is a huge advantage. We are pleased to have in front of us a technically very competent team where the term partnership has all its meaning!

Yes, the answers given above bear witness to this. As proof, we continued to collaborate with qmt for the realization of 2 additional PLCs (following the first experience of 2011).

Note that, even if the machine is easy to use, the "subtleties" of the software require a certain grip. So, as long as the system is satisfactory (which is the case here), we have every interest in continuing with the same product.

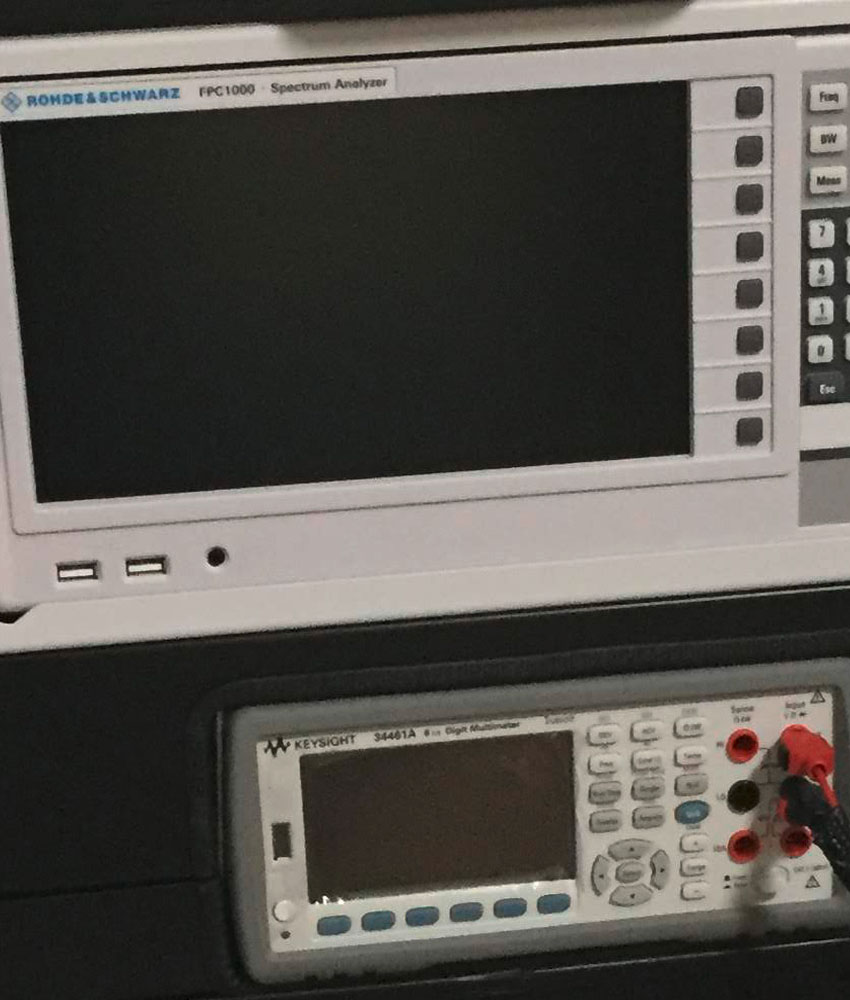

Little has been said about the measurement accuracy of these machines… it's a vast subject, and I don't want to venture into the slippery ground of microns!

I would simply like to remind you that there are physical parameters that are immutable. I simply give 2 examples:

- the larger the field of view, the poorer the resolution

- the more we try to be precise and complete (control all dimensions), the more time the image processing takes, and therefore generates a loss of productivity.

So it's all about balance!

We must never lose sight of the purpose of such machines. The art, both for qmt and for Polydec, lies in the choice of numerous parameters, in order to guarantee maximum customer satisfaction at minimum cost.

All solutions are based on unique software functions

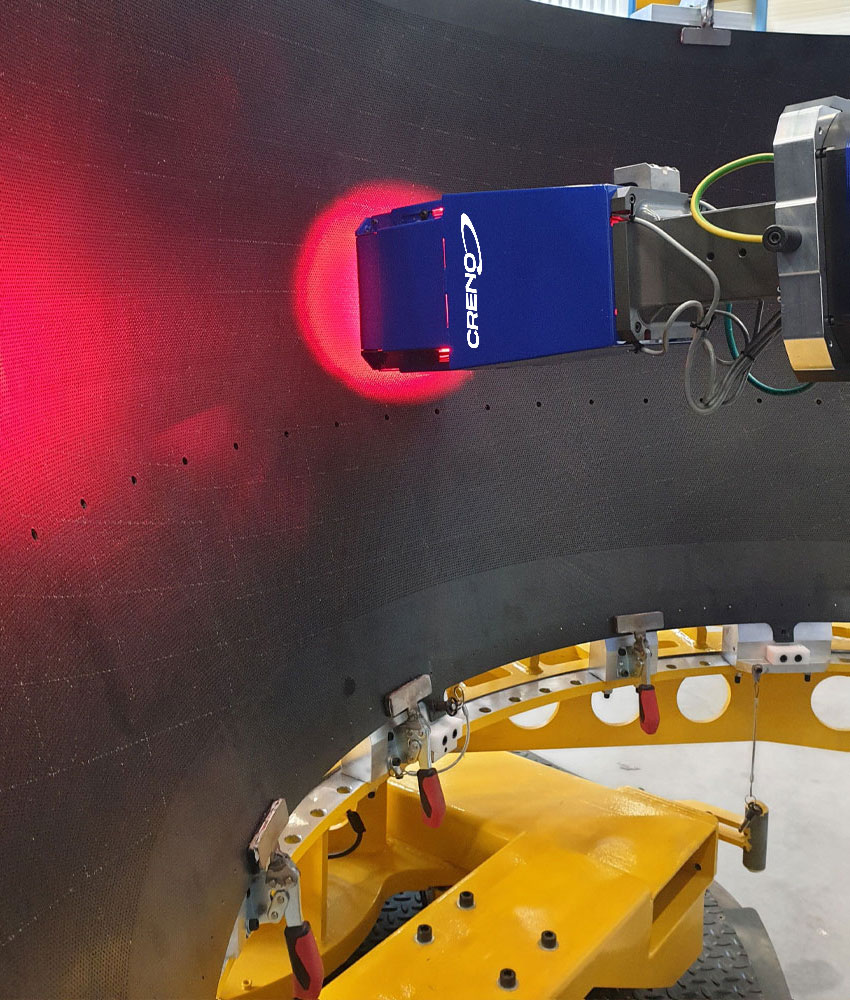

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

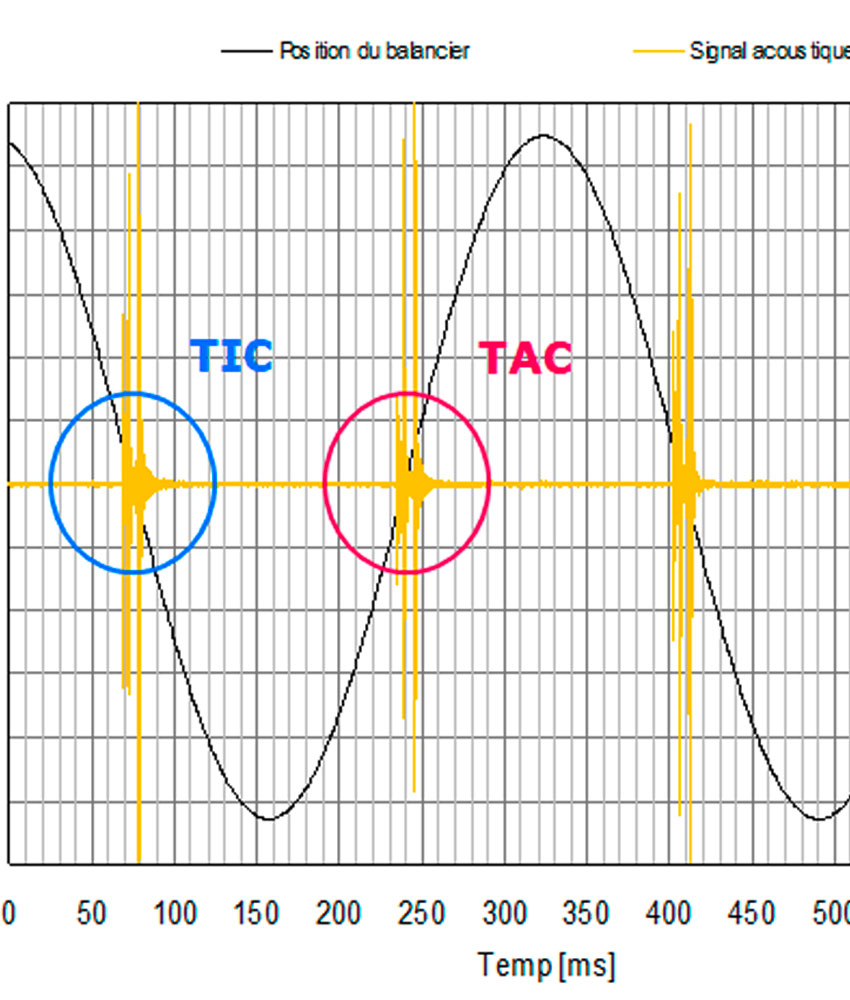

For acoustic and vibration control