Témoignages

QMTProTime for the Master Chronometer certification

Standard test device

Measuring daytime walks of finished watches

The QMTProTime is a daytime rate tester that has been certified by METAS to perform steps during the Master Chronometer watch certification of completed watch heads.

A user explains the use of QMTProTime for the Master Chronometer certification (8:00 of the video).

The strengths of QMTProTime for this application

- Measurement accuracy

- The distribution of the reference time between several systems

QMTProtime technologies

In order to ensure the ability to measure precise daytime steps, the QMTProTiem incorporates the following technologies

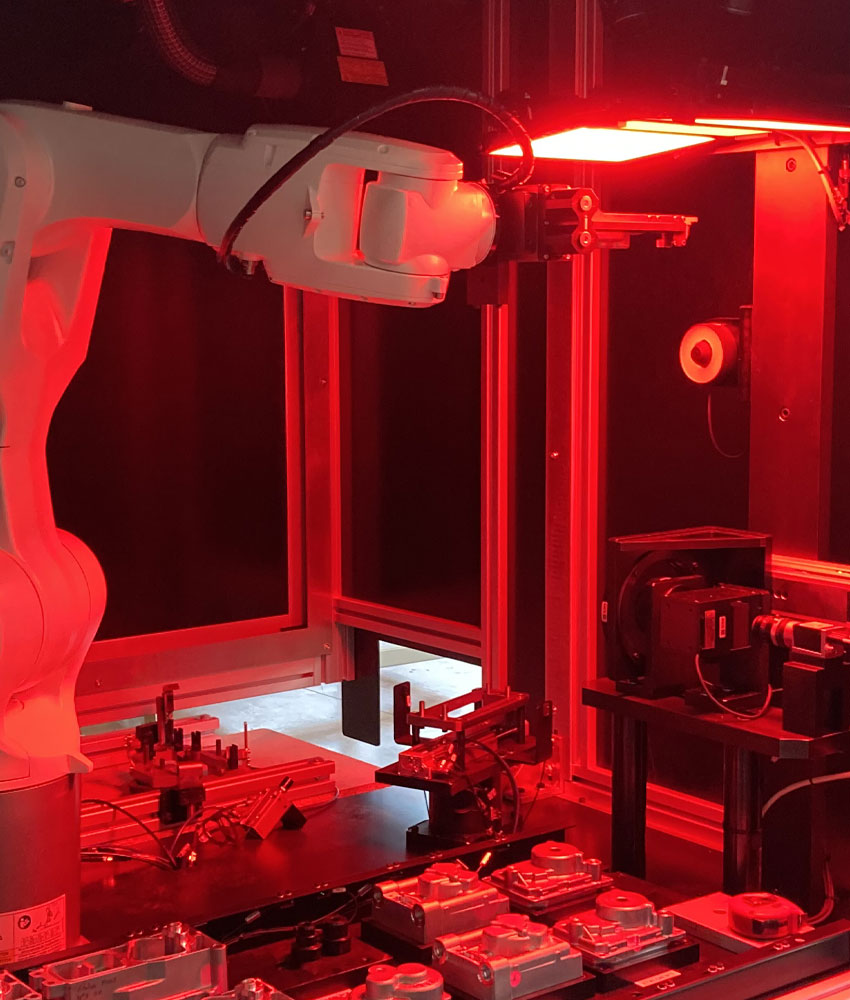

Digital cameras of 2,500 x 2,000 pixels (5MPixels) with an acquisition speed of 90Hz. The camera is electrically synchronized with the time base in order to be able to time stamp the images with guaranteed precision

In order to be able to measure movements in skullcaps and watch heads, a versatile double lighting has been integrated. It enables optimal image quality and versatility

Qualimatest has developed a specific time base for the QMTProTime. It offers a relative measurement of time with a sufficient level of precision.

The computer system is integrated with the equipment in order to have a completely integrated solution that does not require computers

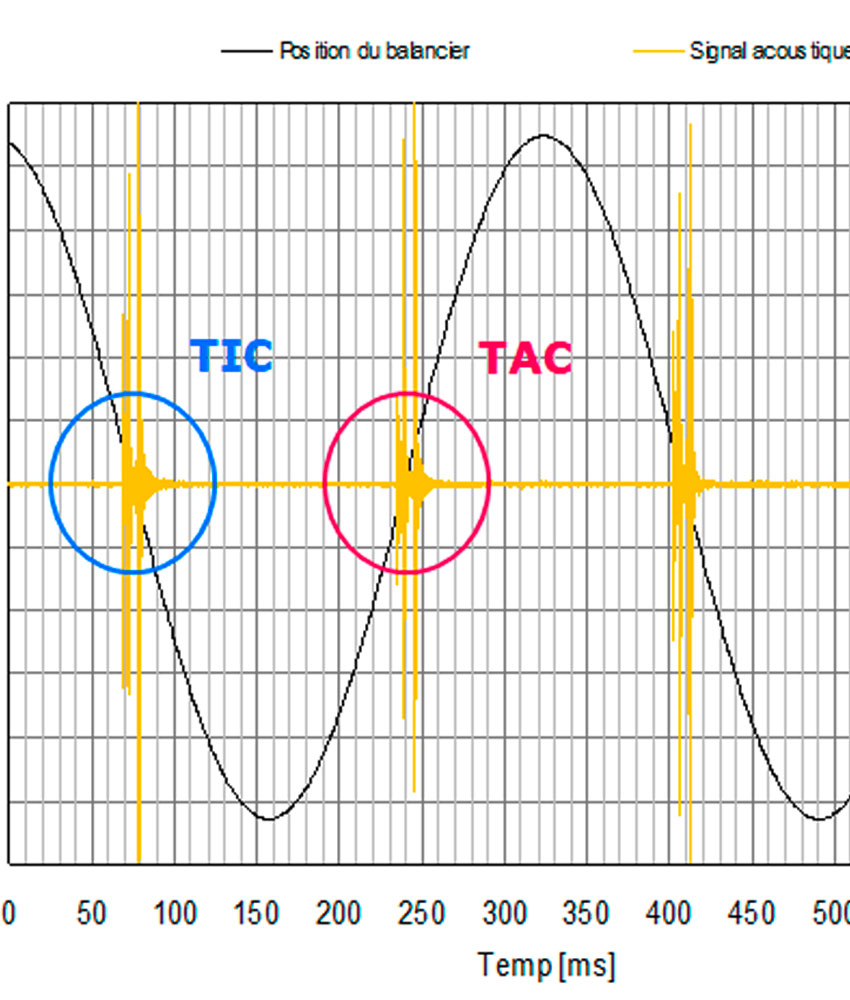

The QMTTimeProcessing algorithm takes into account discontinuous displays (needle skipping for example) and display desynchronizations. New laboratory mode allows high-speed, continuous measurement of indicator position to enable advanced analysis of movement operation

QMTProTime applications

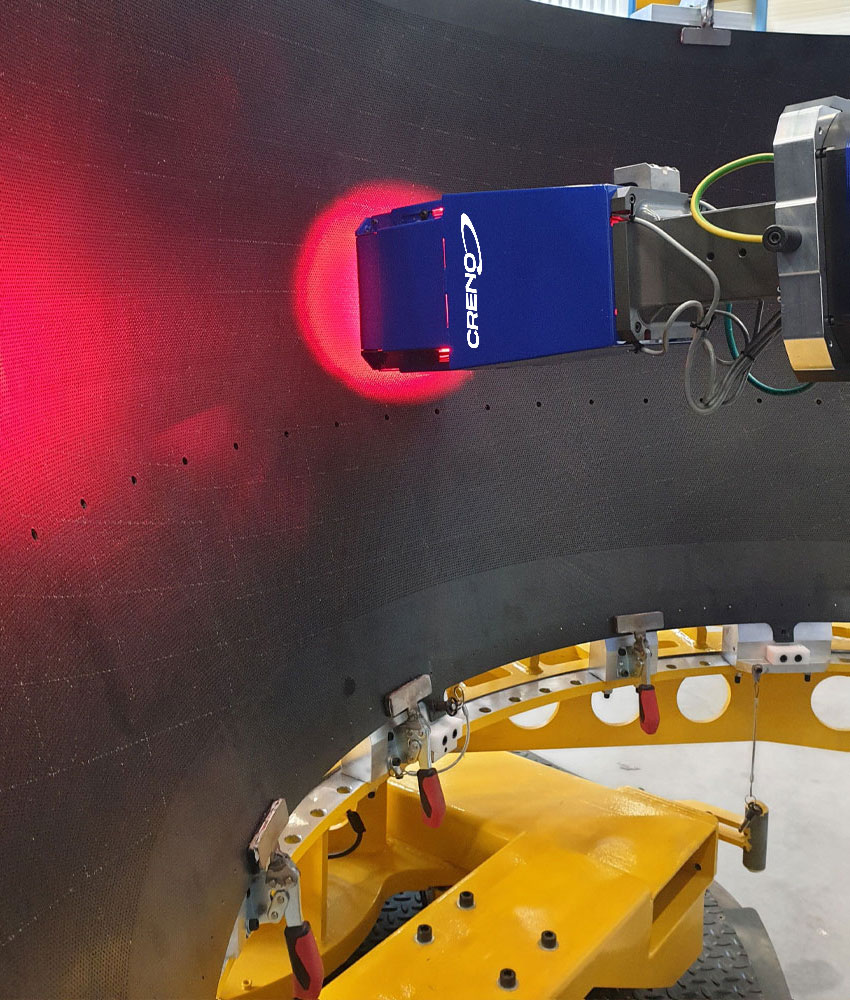

The measurement is based on taking two images of the product spaced apart in time which are temporally referenced thanks to a precision time base. The time indicated by the watch or the two-state movement is given by the position of the hands which is defined in the high resolution image. The rate can thus be calculated thanks to the difference between the difference between the state of the watch and the time difference defined by the time base.

This mode allows high speed reading of the position of all indicators. This function allows an advanced analysis of the operation of the movement to detect any faults

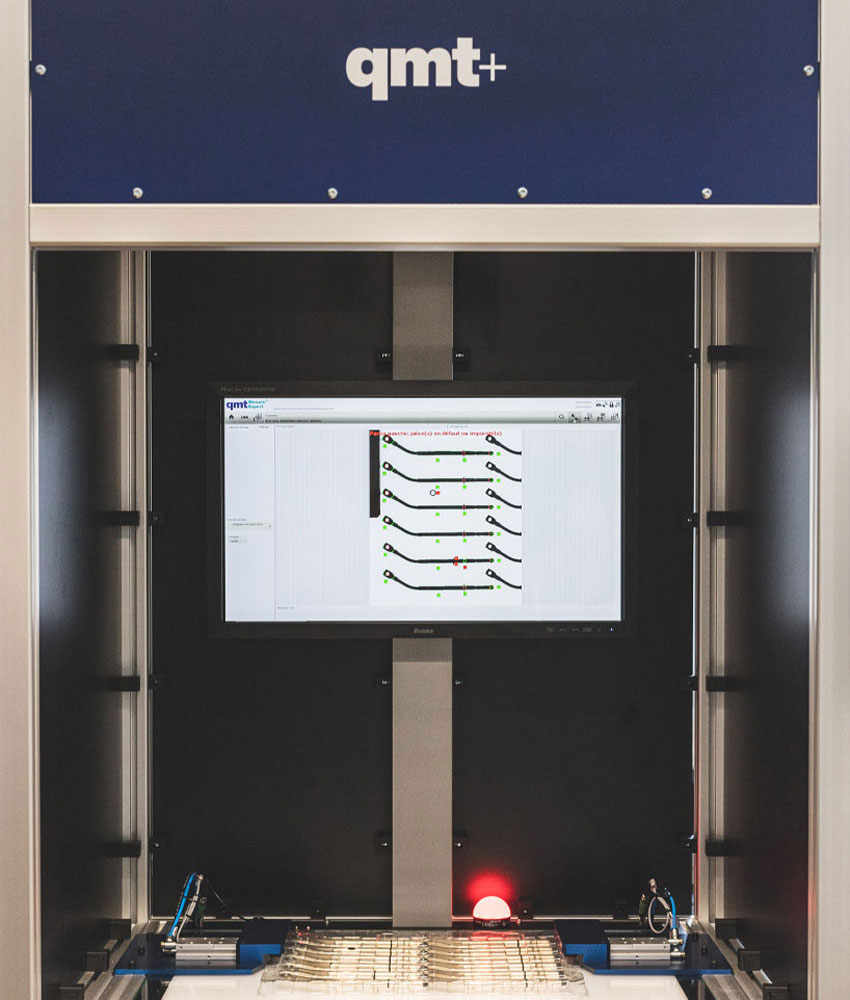

QMTProTime software

The software for high precision step measurement with assisted programming

The control program is carried out using an intuitive interface comprising program templates, standard control equations and functions that automatically detect and offer the characteristics of the part. The operator can thus select the controls and define the tolerances, the control program is thus created automatically. It is also possible to add functions available in the QMTStore or to have a personalized function developed through the Fit For You program.

QMTM Measurement

Fit for you program (FFY)

Qualimatest products can be customized both in terms of equipment and software. The first level of software customization is the addition of additional functions (available under QMTStore) or the development of a custom function.

On the basis of Qualimatest products, it is proposed to produce a labeled product on behalf of our customers who may be private or marketed by themselves.