Témoignages

Robotic quality control for Poppe + Potthoff

This bar turning machine based in Bonneville and Scionzier (74) produces high added value parts requiring very high levels of control.

Integrated multi-criteria quality control

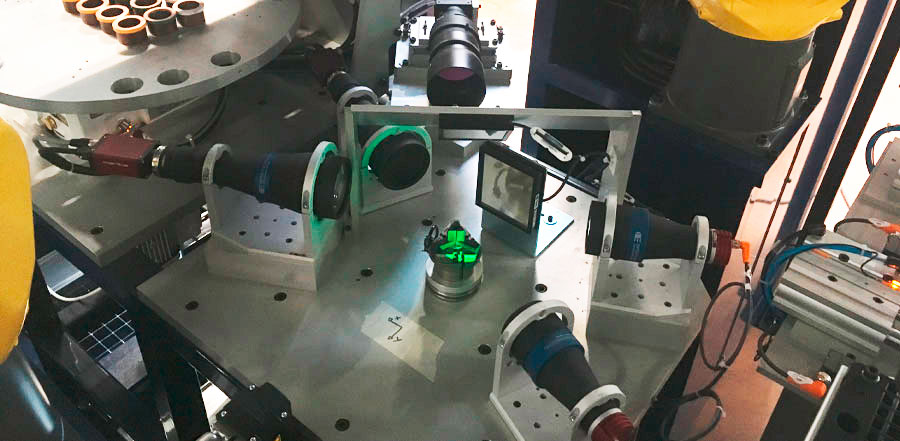

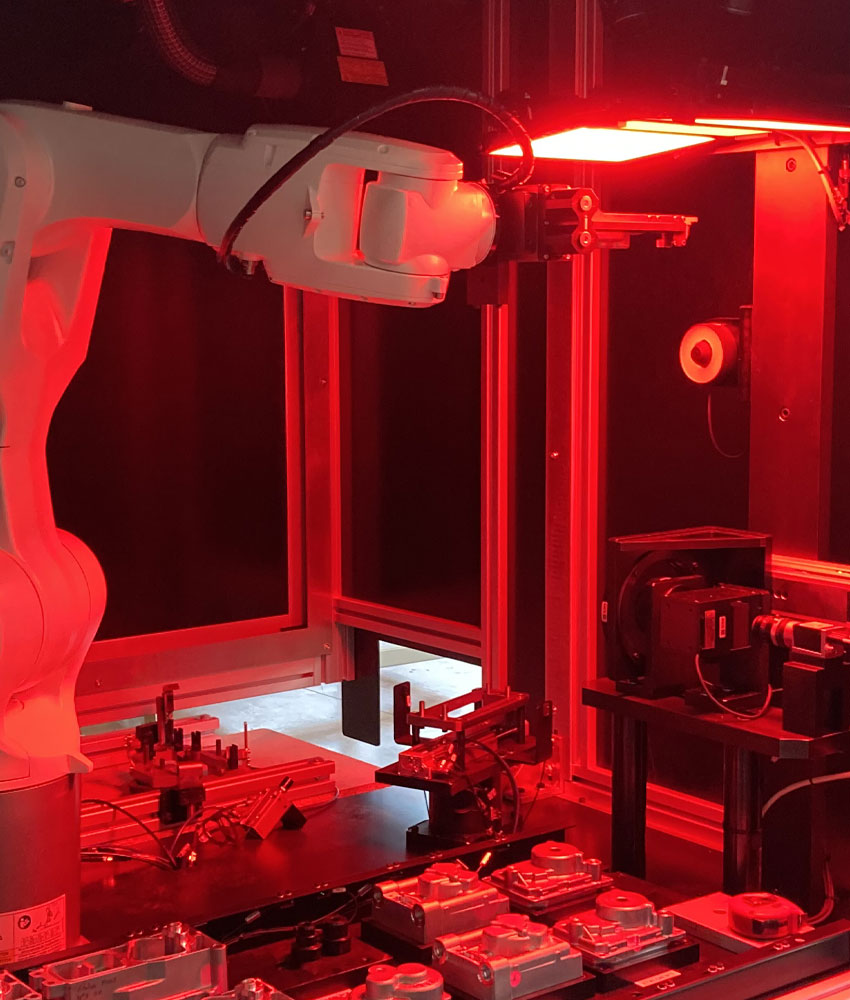

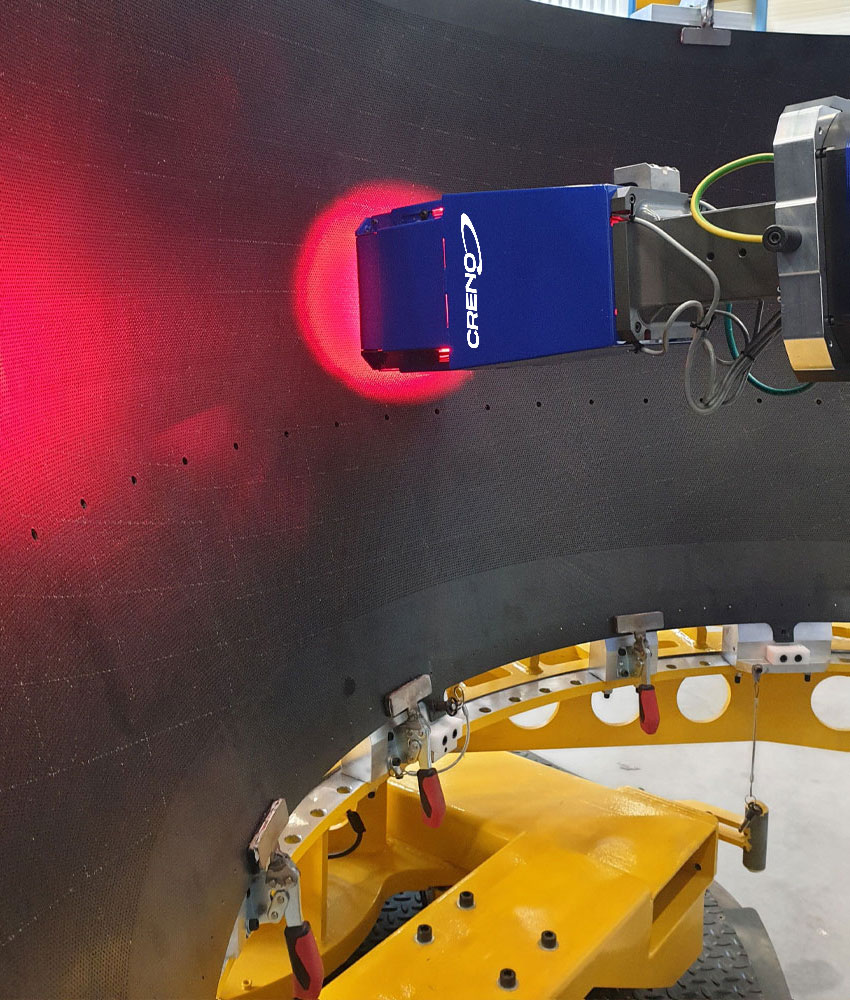

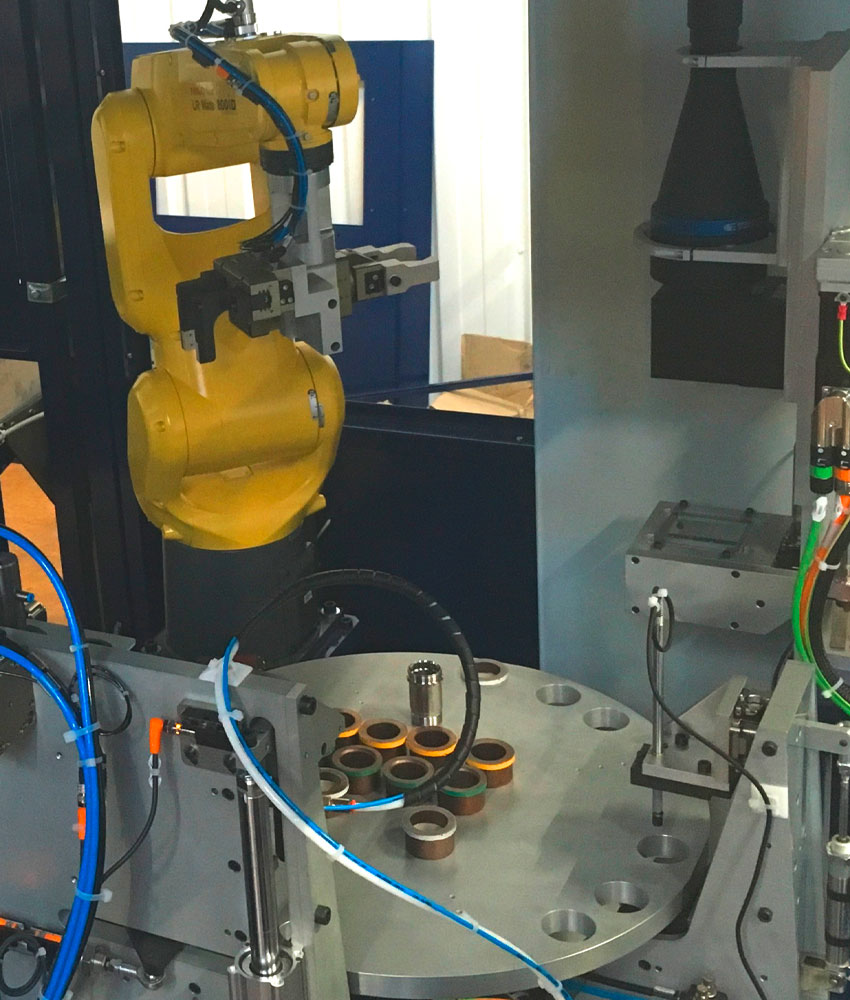

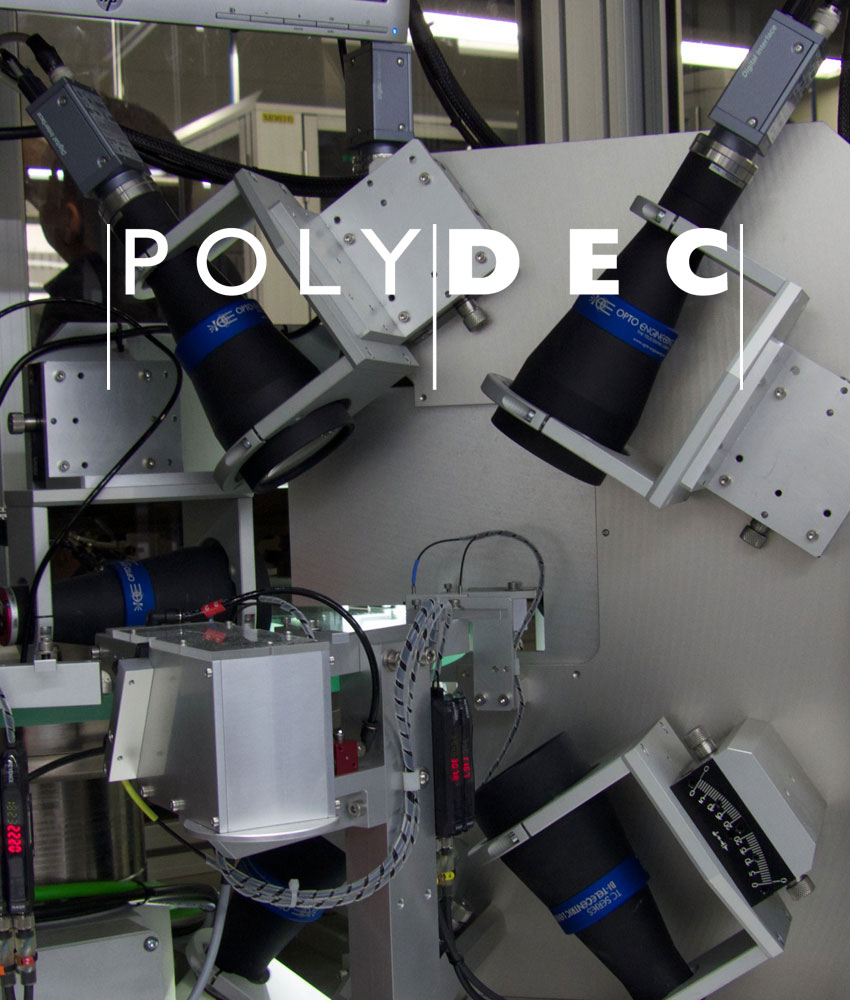

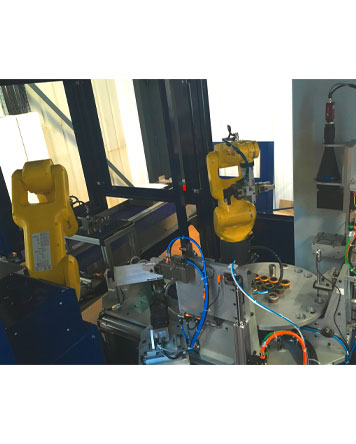

The Poppe + Potthoff company trusted qmt and Techplus to realize an automated control cell for engine parts requiring perfect geometry, optimal cleanliness and the absence of chips. Techplus and qmt proposed a cell equipped with 3 robots and 4 machine vision stations to ensure the control of parts with 4 different references as soon as they leave the washing machine.

qmt is proud to support its clients in achieving excellence

A first robot loads and unloads the parts and 2 other robots handle the parts on different sets or control platforms in the cell. The 100% controlled parts are directly evacuated on thermoformed trays. This technical solution allows flexibility, control performance and a high throughput.

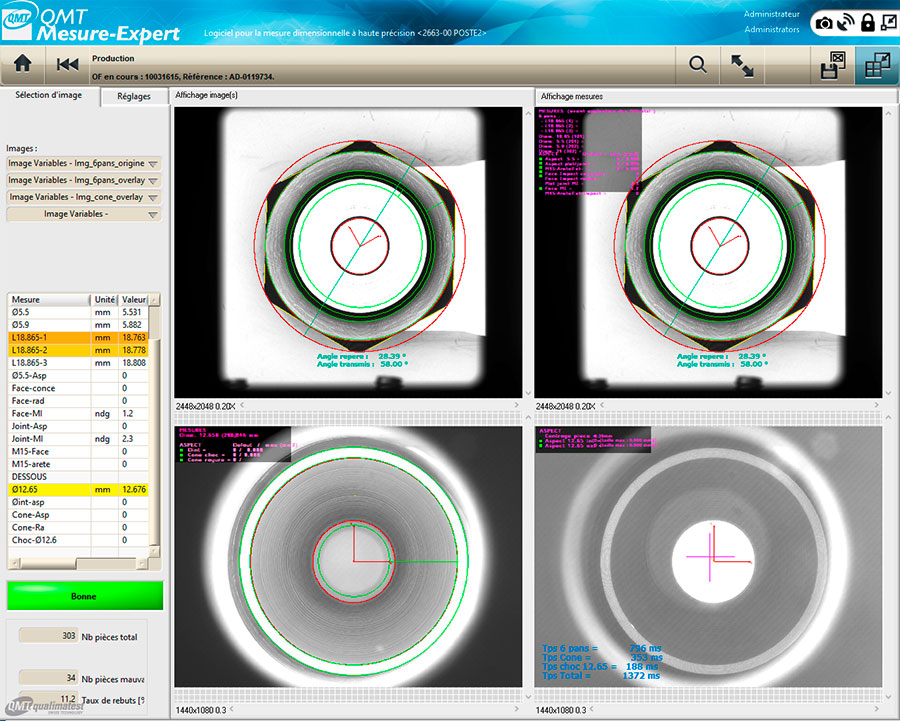

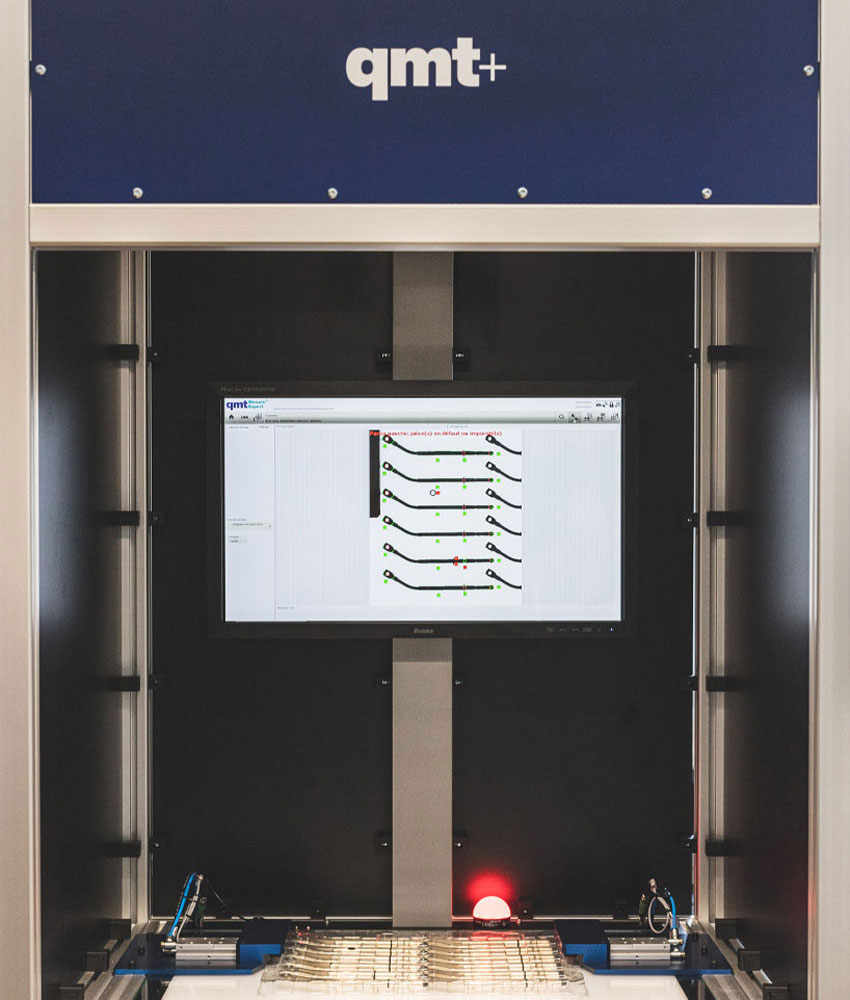

On the vision side, the qmt Vision team has designed 4 vision stations in order to carry out more than 30 various checks on 4 references:

- Dimensional checks lengths and diameters with an IT of 10 microns

- Appearance check with search for shocks on the skirt of the part

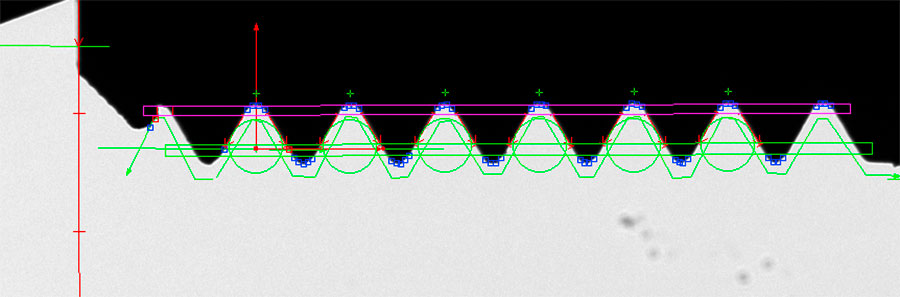

- Simulation of mountability control by vision using virtual rods and comparison of profiles by DXF. This control of very high added value was a strong expectation of the bar turning sector.

Additional mechanical dimensional checks by pads and probes are carried out as well as laser engraving and anti-corrosion soaking.

The advantages of the proposed solution:

- A high rate of 14 seconds per part

- High machine availability (3X8 over 7 days and 47 weeks per year)

- Great autonomy

- High system scalability

The robotic control machine solution is perfectly suited for complex parts requiring a large number of controls.

For 90 years, The Poppe + Potthoff group has been developing and producing steel tubes, common-rail subsystems, high pressure pipes, precision components, shaft lines and couplings as well as special machines and corresponding test stands. to customer specifications. Thus, Poppe + Potthoff provides high-level technical solutions in the automotive and commercial vehicle sector, the shipbuilding industry, tool and machine construction as well as other industries.