Innovation

qmtrelief- High speed image acquisition with increased relief

The contrast of reliefs at high speed qmt relief

qmt relief allows the highlighting of the micro-geometry of a surface (maps in slopes and curvatures). Based on the “shape-from-shading” or “stereo-photometry” technology (Horn, 1989) which makes it possible to highlight appearance defects (scratches, pitting, etc.). qmt relief brings significant improvements in order to be able to integrate it into an industrial process

- Removal of coloring information to see only the relief (see image which shows the image with qmt relief compared to the base image)

- The image acquisition is instantaneous, it is thus possible to make a dynamic measurement at high speed

- Filtering of periodic components to facilitate the detection of appearance defects

qmt relief can thus be integrated into a QMTCheck measuring station on the production line or for a sorting machine.

Stereo-photometry was introduced by Woodham (1980), it makes it possible to find the normal at each visible point of an object from several photographs taken from the same point of view but for different lighting directions. This is an extension of the special case of shape-from-shading where the data to estimate the normals field is a single image, which is known for its ill-posed character. Stereo-photometric techniques generally assume that the surface of the inspected object follows the Lambertian reflectance model; ie the luminance observed at each point of the surface is proportional to the cosine of the incident angle of illumination

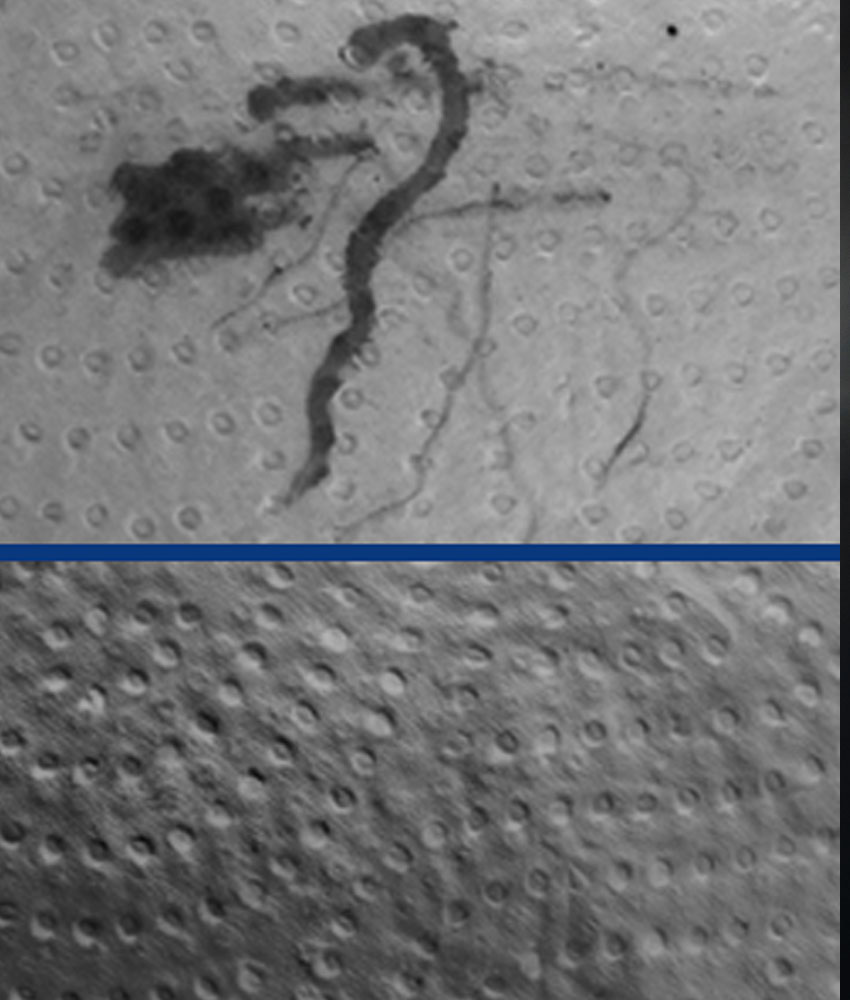

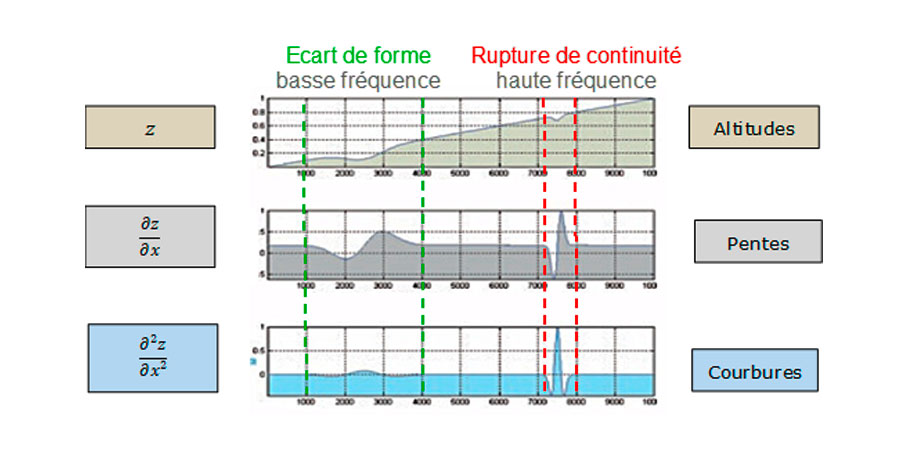

From the normals obtained thanks to the resolution of the general equation of stereo-photometry, we can derive this information to obtain the information in curvatures. Curvature is a property that describes the rate of change of direction of a curve, or surface in a given direction. The following diagram illustrates the advantage of obtaining an estimate of the slopes and curvatures at the surface. Indeed, the human eye is very sensitive to the shape discontinuities of a surface. These variations are reflected in terms of slopes by a strong local variation, and in curvatures by significant curvature intensities at the location of the anomalies. In the curvature information, we see that the shape of the surface (the low frequency component) is filtered, highlighting the information related to the micro-geometry (high frequency component) of the surface, thus facilitating the detection of appearance defects!

qmt relief allows instant image acquisition, so it is possible to control a moving part. The continuous processing mode is fast enough to enable high-speed production line control.

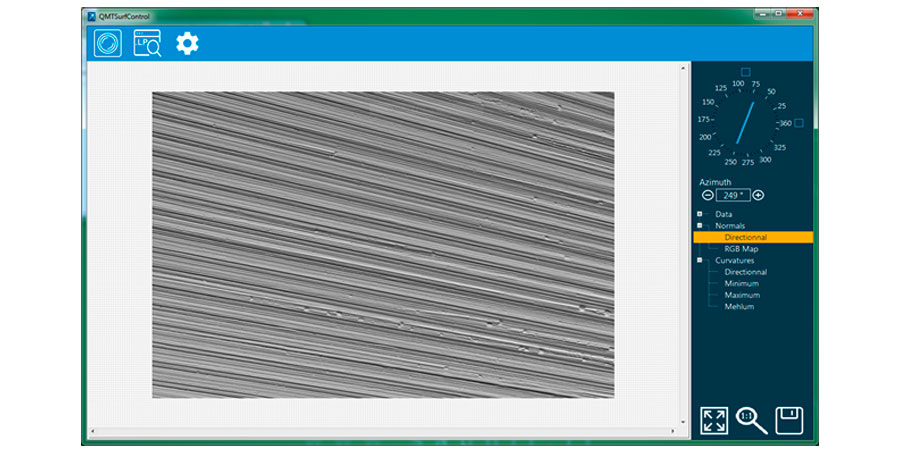

Software functions have been developed to control the stereo-photometric acquisition system and process them in order to calculate the following maps

- the directional normals (according to a chosen direction of projection)

- the "normal map" (in color)

- directional curvatures (according to a chosen direction of projection)

- maximum curvatures

- minimum curvatures

- the curvatures of "Mehlum"

Two modes of use are available

- High-speed continuous acquisition and computation

- Loading a set of existing images from an LP file

qmt relief allows the creation of an aesthetic control system on shiny or matt pieces, with patterns, rough or smooth. Other applications requiring surface curvature information are possible, such as the detection of watch hands.

Examples with qmt relief

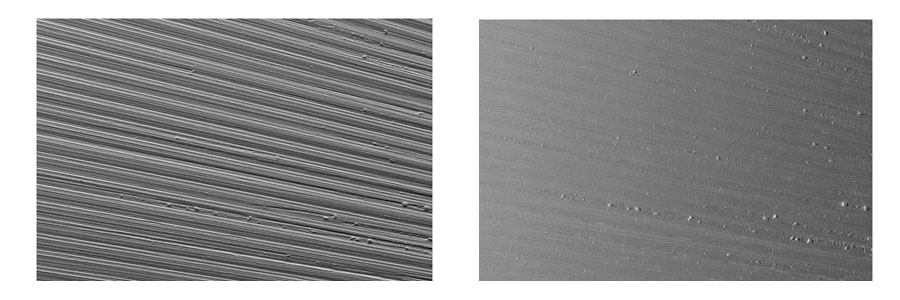

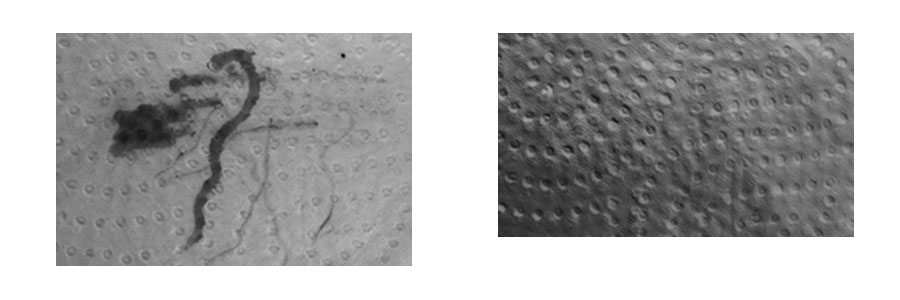

The image on the left in traditional mode is to be compared with the image on the right with qmt relief . We see that the differences in color of the part are eliminated and therefore that the relief of the part is much better visible.

We see that qmt relief allows the removal of the design which has no relief (traditional left image) in order to highlight the relief of the part (We only see the relief on the right image).

In this example, we observe the ability of qmt relief to contrast the reliefs present on the part (right image to be compared to the traditional image on the left).

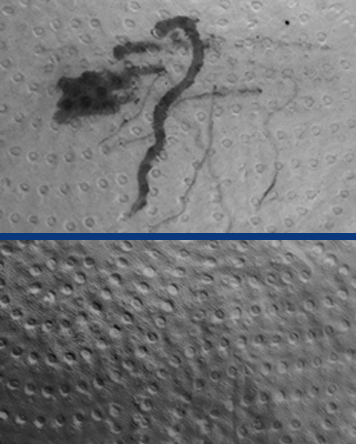

qmt relief allows a treatment with a specific orientation in order to focus the search on reliefs having a specific orientation. In this case we see the image with an oriented processing to visualize the relief of a decoration to be compared with the image of the same part with a search oriented at 90 degrees which allows the search for defects.