Technologies

Quality control in acoustic resonance

Inspection by listening to the product

In line with its technological strategy, qmt offers mechatronic automatic test and quality control systems equipped with various inspection technologies, in particular acoustic resonance inspection.

With more than 30 years of experience in this field, qmt offers acoustic inspection solutions, sometimes combined with other inspection physics, such as for example inspection by machine vision. QMTMultiSens is a good example of a qmt product offering the possibility of coupling acoustic and optical inspections in an acoustically and optically isolated and controlled environment.

Any object vibrates!

Every object vibrates and every object has its own modes of vibration. Each vibration mode represents a standing wave or a resonance at a natural frequency. Normal modes of vibration are specific to the object. They correspond to the “Acoustic Footprint” of the object. They thus describe the intrinsic dynamic properties of the object. To make a more precise definition, a "Mode" of vibration corresponds to a degree of freedom of sinusoidal vibration damped at a natural frequency. The "Vibration" of the object is the superposition of all its Modes of vibration.

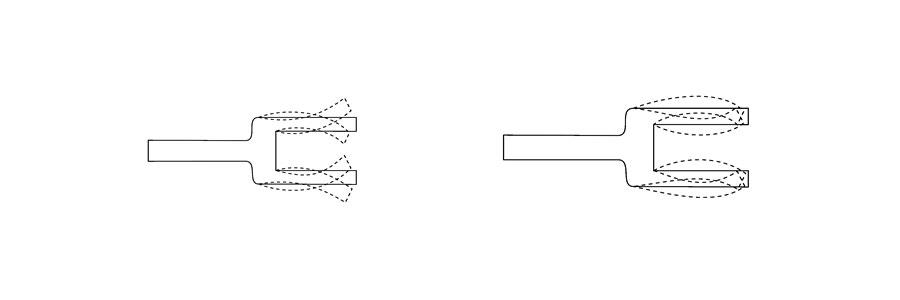

Two simple examples of Vibration modes:

To read the modes of an object and thus determine its acoustic imprint, it must be excited, either by an impact or by applying a "sweeping sine wave". This is often done by hammers or by piezoelectric elements.

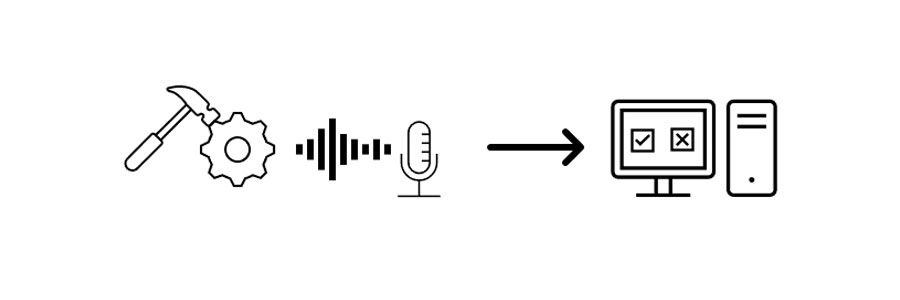

The different stages of acoustic quality control: excitation, acquisition of the acoustic signal, analysis and comparison of the footprint for sorting:

While vibrating, Modes appear at their specific frequencies (sometimes called natural frequencies or eigenfrequency). The number of Modes and natural frequencies of each object is infinite.

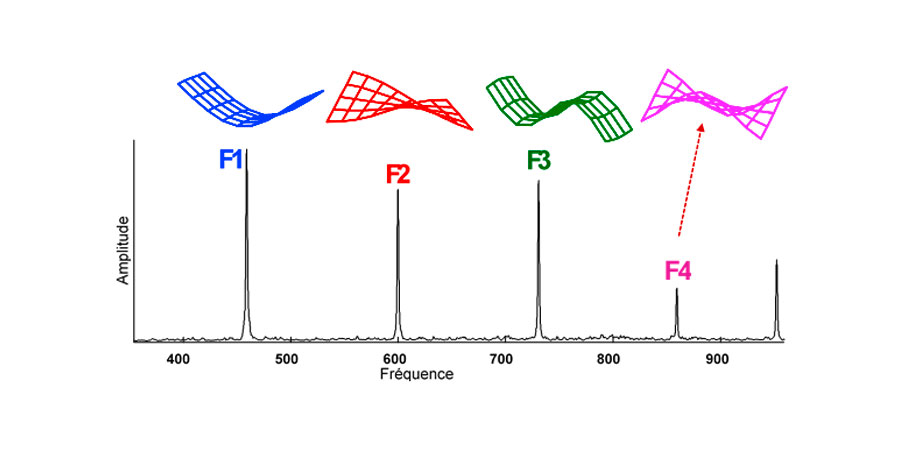

Example of an acoustic signature

each vibration mode (blue, red, etc.) appears at a precise frequency with a certain amplitude specific to it

The frequency of the modes and the amplitude of the signal depend on the elastic properties of the object as well as on its geometry. It is interesting to know that this imprint does not depend on the point of impact of the excitation, on its intensity or on the position of the sensor. It is therefore possible to use the acoustic imprint to compare two similar objects, or even to carry out quality control by acoustic resonance.

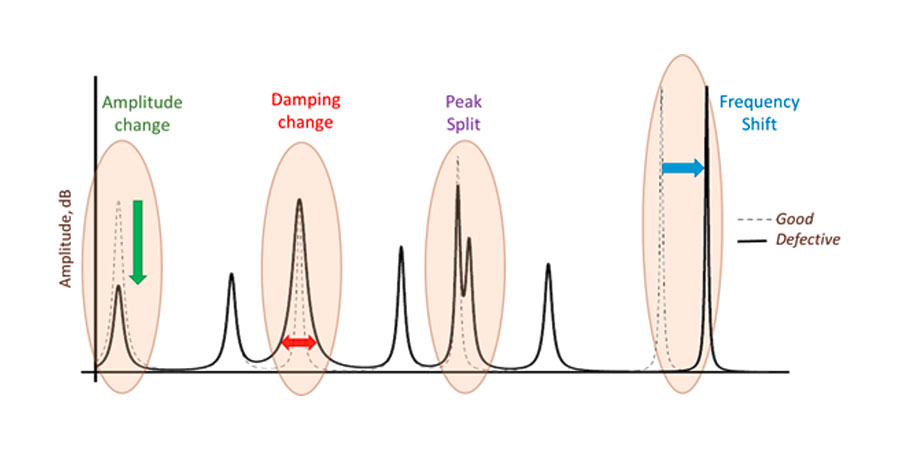

Schematic example of the influence of a defect on the acoustic footprint:

A defect changes the elastic properties of the object and therefore its acoustic imprint. The figure above schematizes some of the modifications of the imprint which make it possible to detect a defect in a room by an acoustic inspection.

Checking the integrity of parts

According to ASTM-E2001, acoustic inspection can be used to detect defects in metallic and non-metallic parts. In a single measurement, the procedure can detect many defects, including cracks, chips, cold shots, inclusions, voids, oxides, contaminants, failed processes or operations, and variations in size, hardness, granularity (nodularity), porosity, density and heat treatment.

Type of detectable defects according to the material:

- Ductile or gray iron: Nodularity, crack, oxide, cold closing, porosity, heat treatment, inclusions, carbide, hardness, residual stress, perlite

- Steel: Cracks

- Aluminum: Crack, oxides, elongation, cold seals, shrink porosity, blow holes

- Ceramic and glass: Cracks

Sound level measurement

In the acoustic field, the sound level is often expressed in decibels. This value implicitly indicates the power ratio between the measured quantity and the reference value which corresponds to a sound too weak to be heard.

Example: If P 1 is 100 times more powerful than P 0 , X dB = 20dB, ie it is 20dB more “loud”. And if P 1 is 1000 times more powerful, it will be X dB = 30dB more loud. Acoustic intensity is a power quantity expressed in watts per square meter (Wm −2 ). The ISO 80000-8: 2007 standard defines a reference sound intensity level of 1pW / m 2 as 0dB. It is in relation to this reference that the sounds are estimated in dB.

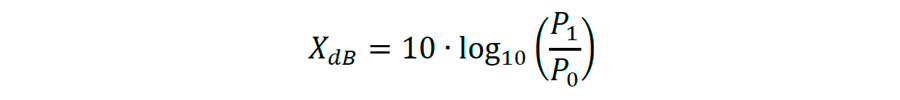

Consider two acoustic powers P 0 and P 1 , their relative value in decibels is: