Témoignages

LPM TPM on-board system for Speno

An on-board system as an OEM product

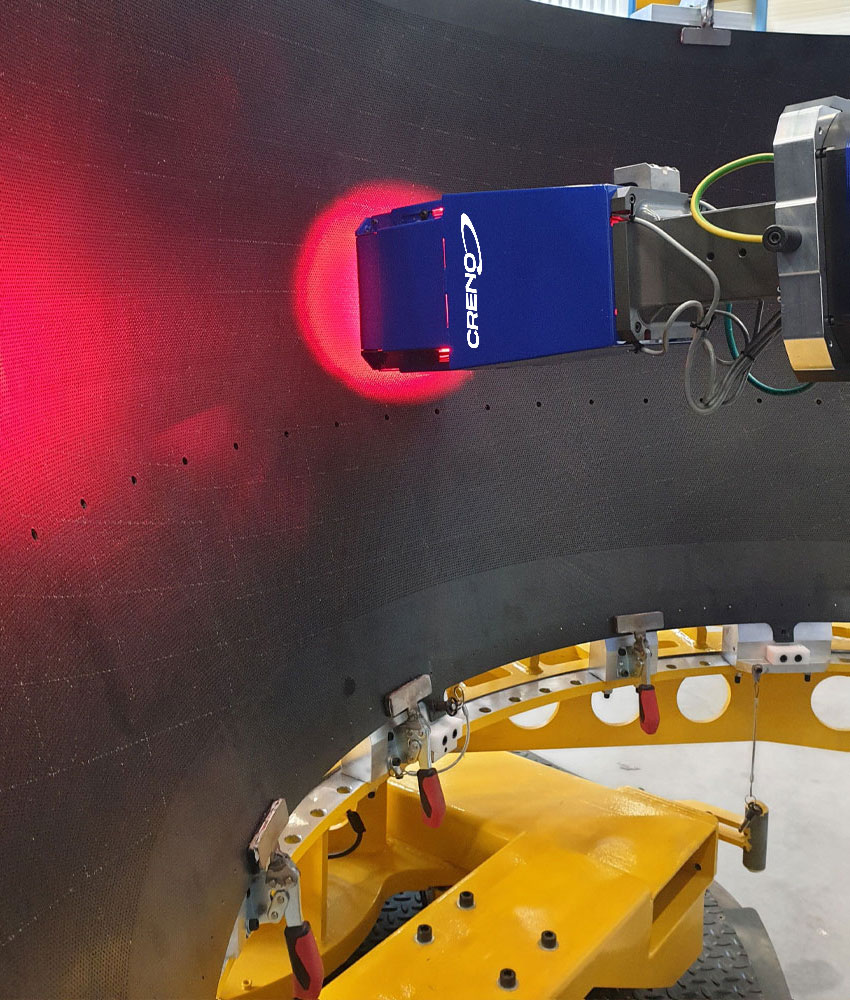

Track control switches to contactless

As the train passes, the rails wear out. To maintain them, Speno designs trains fitted with grinding wheels. They use rail profile measurement systems. Grinding is carried out according to the results obtained. Previously operating contact measurement sensors, the Swiss company has modernized its measurement systems by providing them with optical technologies. She took the opportunity to develop the PXI processing and visualization platform. The application programmed under Labview now runs on a single PXI controller with a multi-core processor ...

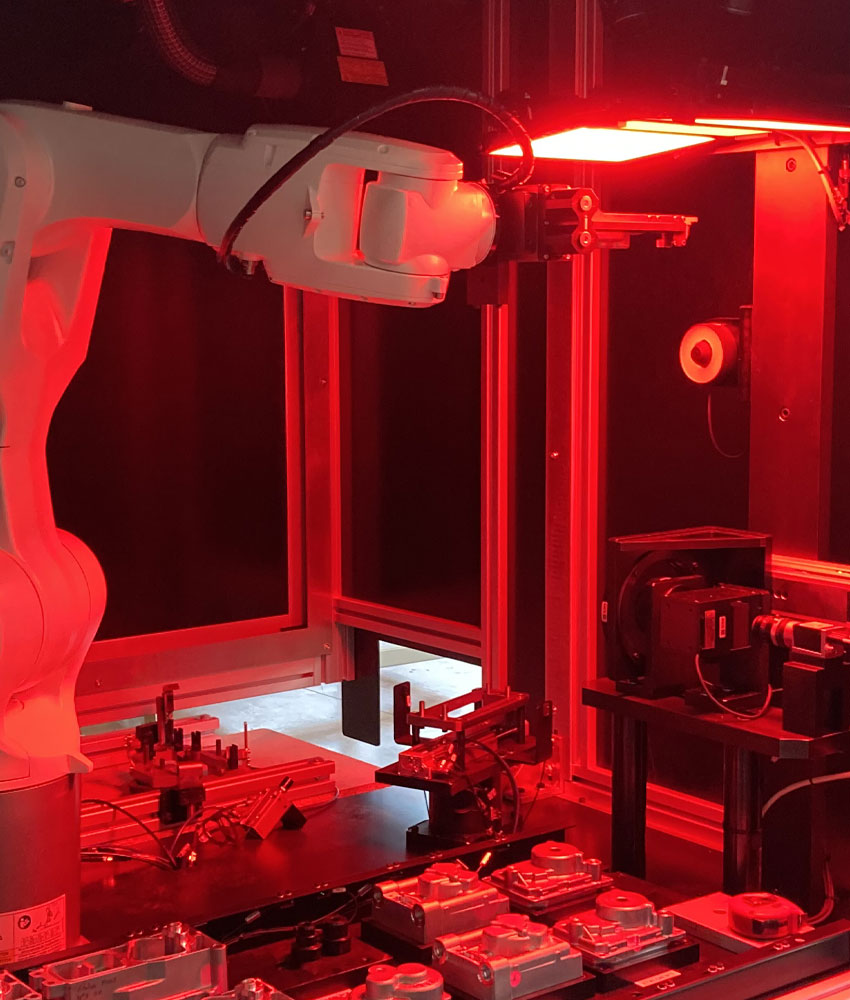

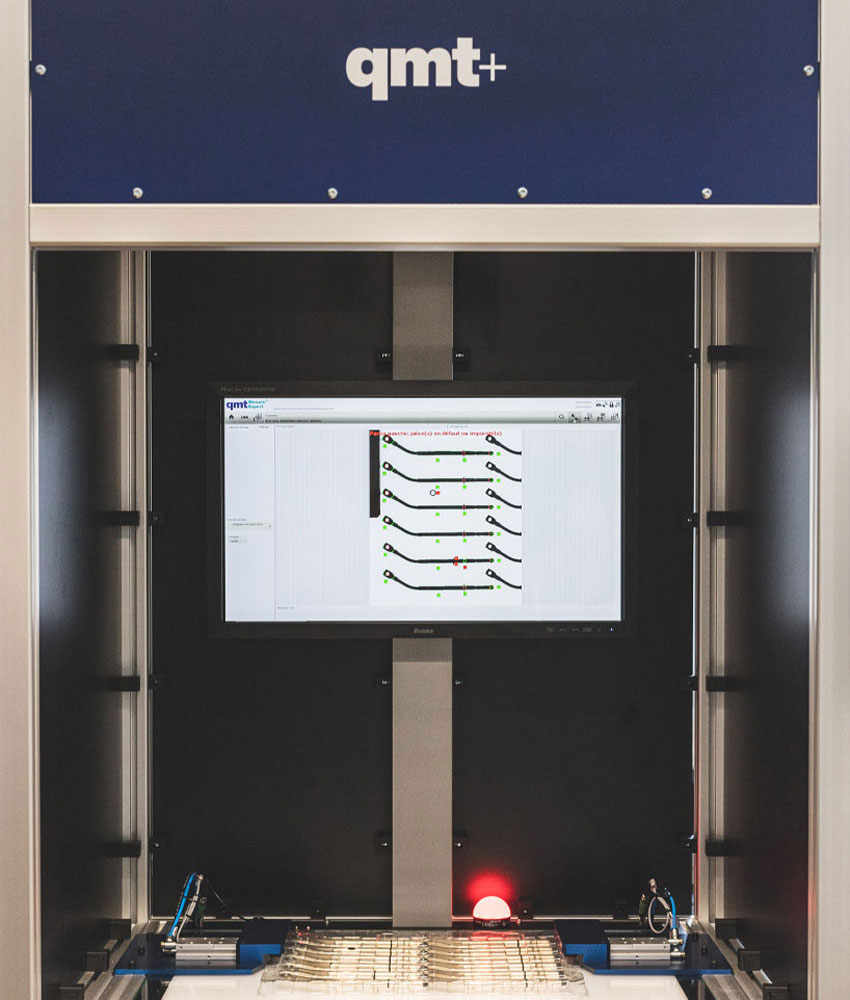

Movie playbackThe creation of a measurement system using contactless technologies was accompanied by the renovation of the signal acquisition and processing platform. This is based on modular instrumentation in PXI format. It is installed in the driver's cabin of the train which controls the grinding operations according to the results recorded by the measurement system. On the supervision screen, the driver visualizes the transverse profiles of each of the two rails. This real profile is superimposed on the templates with the reference points defined by the railway operator. Under each of these points, a bar graph indicates whether the dimension measured is within the required tolerances (a point outside of tolerances is indicated in red). The measurements related to the irregularities of the rail on its upper part (longitudinal profile) are presented just below on the same screen. They are broken down into three categories according to their wavelength (short, medium, long). For each of them, tolerances are determined. Grinding must be carried out when those established for the longitudinal and transverse profiles are exceeded. Until now, the acquisition, processing and supervision system was managed by three controllers associated with acquisition cards in PXI format. A PXI controller was responsible for the man-machine interface, another for processing measurements relating to the transverse profile of the rail and a final one for processing data related to the longitudinal profile. The first used an application produced under the National Instruments graphic programming environment Labview and the other two embarked an application produced under Labview Real Time, in order to ensure the provision of information in real time. The operator thus viewed the profiles in real time just after the grinding wheels had passed. Although Speno opted for standard PXI controllers and instruments, it has nevertheless developed a chassis that meets railway constraints. "It is equipped with a removable power supply on the front and industrial connectors of the military type and it is placed on silentblocs", describes Vittorio Carchia who also explains that the PXI option was chosen for its durability: "c ' is what we were looking for and what dictated our choice. We did not want to redevelop the software according to the evolution of the hardware. Software development and hardware integration of this solution have been entrusted to qmt .

For the management of the new optical measurement system, the number of PXI controllers has been reduced considerably thanks to the advent of multi-core processors. A single controller is now sufficient to control the three applications. This has contributed to the reduction of system costs, simplification of connectivity, backplanes, software development, hardware integration and overall maintenance. Initially, it was planned to distribute the three applications on dedicated cores but the feasibility study made it possible to realize that it was possible, thanks to the performance of the multi-core processor (dual core processor T7400 Core 2 Duo 2.16 GHz from Intel which equips the NI PXI-8106), to do without development under Labview Real Time. All Labview applications were developed under Windows XP. “One of the main attractions of Labview is that it is possible to change the material without modifying the program very little. But for this development, we have chosen to start from scratch to better take advantage of the new Labview tools. It was not a software compatibility problem, ”reports Vittorio Carchia.

You can read the full article: October 2011 Measure Article