Témoignages

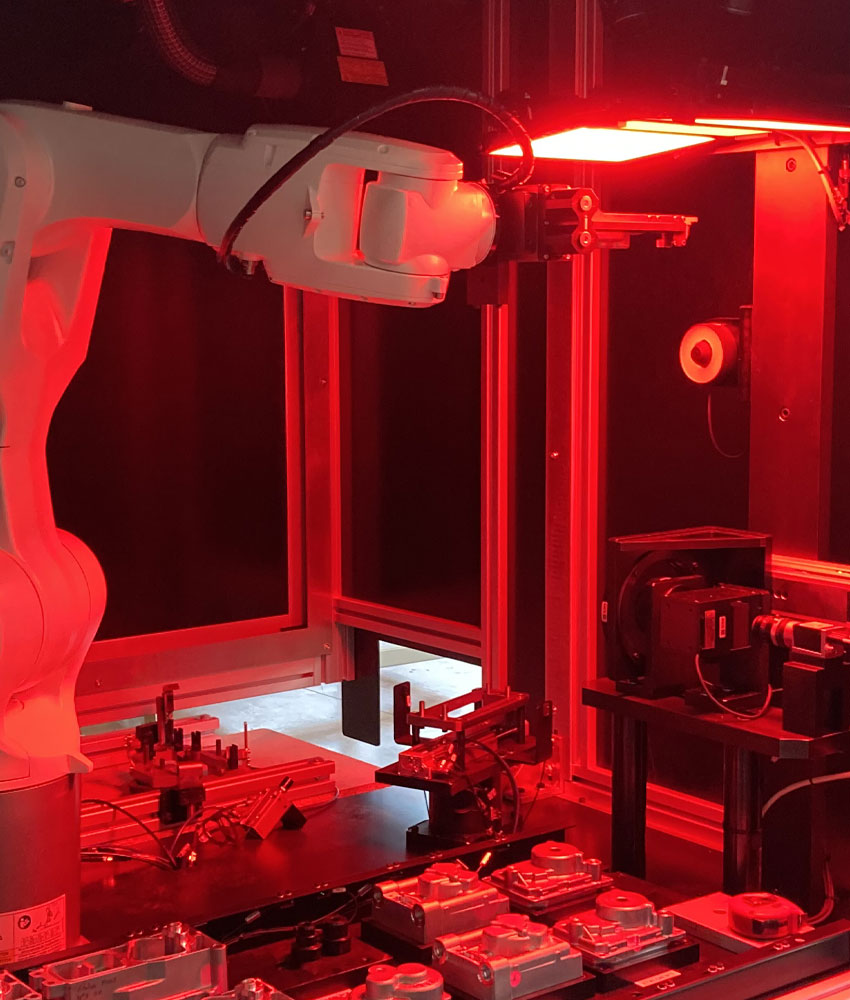

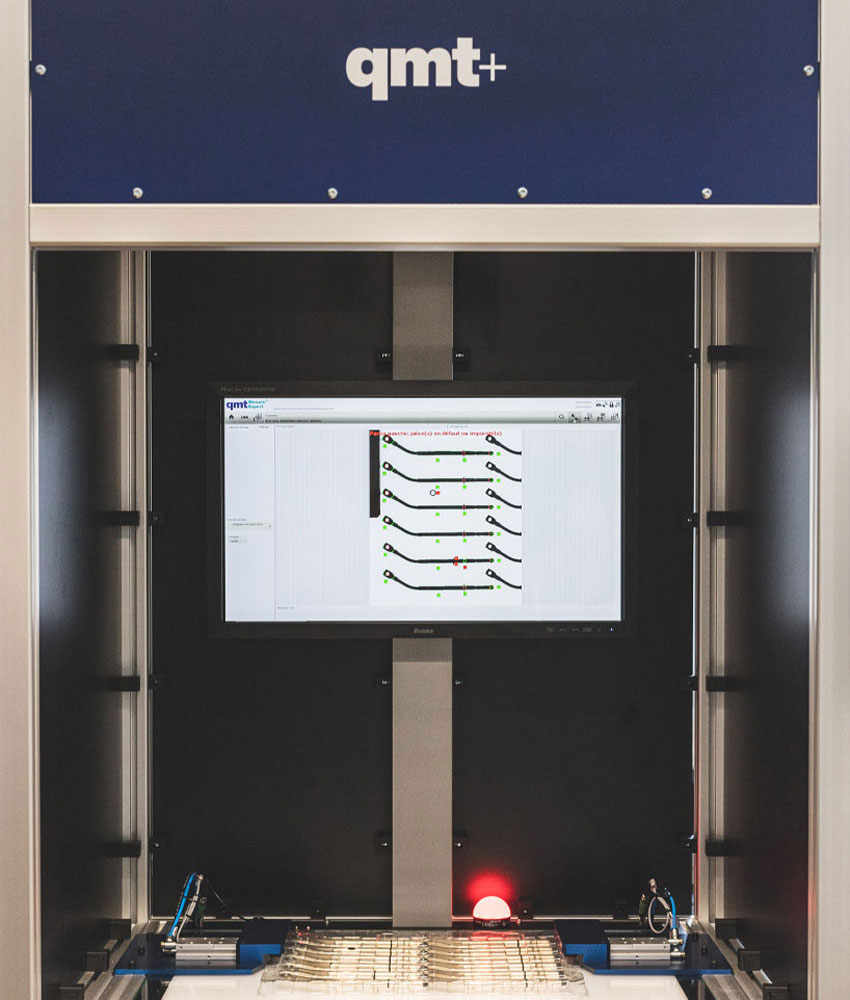

A sorting machine for SAMAT

First of all, a few words about our company: SAMAT is a subsidiary of the HPO group which brings together the companies PRECI-Decta, SPO-MB'TEC based in the Arve valley and HPO Hungary. On the SAMAT site, we produce auto parts by cold stamping. We already have quality control systems by vision.

The automotive sector is an activity where excellence is expected. The quality of our products must be beyond reproach. A 100% control of our productions before delivery is a necessity, mainly on our parts which are involved in strategic bodies of vehicles of large car manufacturers.

PRECI-DECTA, our “sister” company to SAMAT was already in contact with qmt and had recently invested in a first standard QMTInspect-C sorting machine.

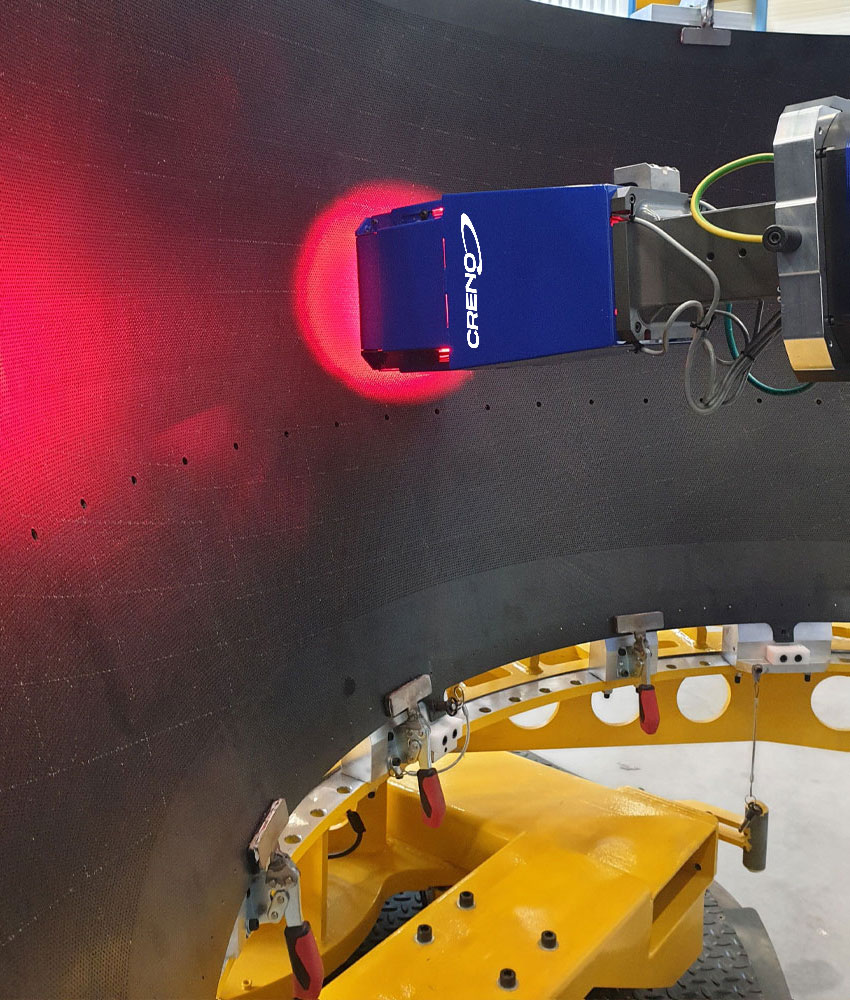

As part of a feasibility study of vision control on a turning part, we had to collaborate with the qmt teams. qmt had the reputation of great expertise in industrial vision, we expected our partner to have advanced technical expertise in order to guarantee us an optimal level of repeatability of the expected measurements. In their laboratory, qmt produced a vision station representative of the serial solution and convinced us, in the light of the results, of its total mastery of this technology. This first step had confirmed our interest in consulting qmt on a project to produce a standard sorting machine.

PRECI- Decta had invested in a qmt machine and the development went well.

The sorting machines manufactured by qmt all come from the same technological platform, this guaranteed us a homogeneity, at the level of the HPO group, of the sorting solutions. In addition, the sorting machines offered are standard models already used by many companies.

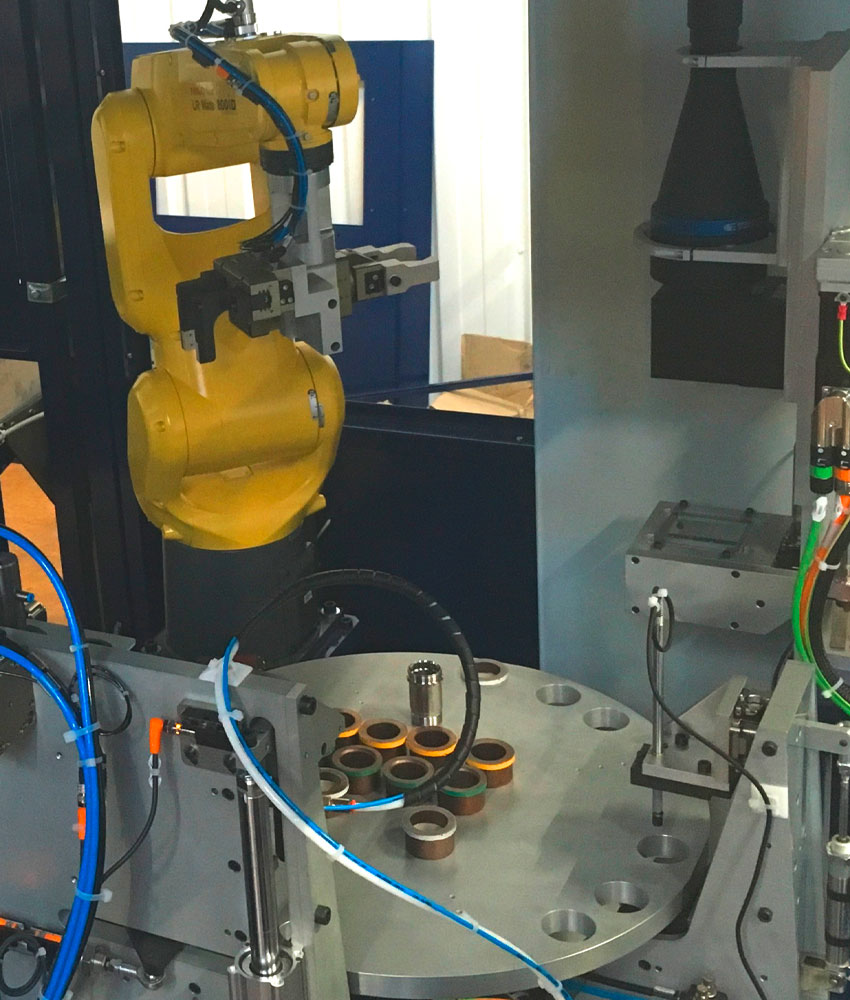

As part of our project, given our high demands (rates, large population of parts), we needed to be accompanied and guided in our investment process. qmt has dedicated a project manager to us from the acquisition phase to the delivery of the machine. The management of our project by a single person is very significant in terms of robustness and efficiency. qmt collaborates on the mechanical part with the company Prosys based in Fillinges. qmt perfectly manages the interface between all the main players.

Although coming from a standard base, this sorting machine model is flexible and allows the concept to be further developed to sort other parts over time.

qmt is a serious company, well organized and on a human scale.

Geographical proximity is a major asset of responsiveness.

qmt offers a whole range of services, from vision training to maintenance contracts for their machines.

I would say that at qmt "Swiss Made" it is above all a question of rigor and team availability.

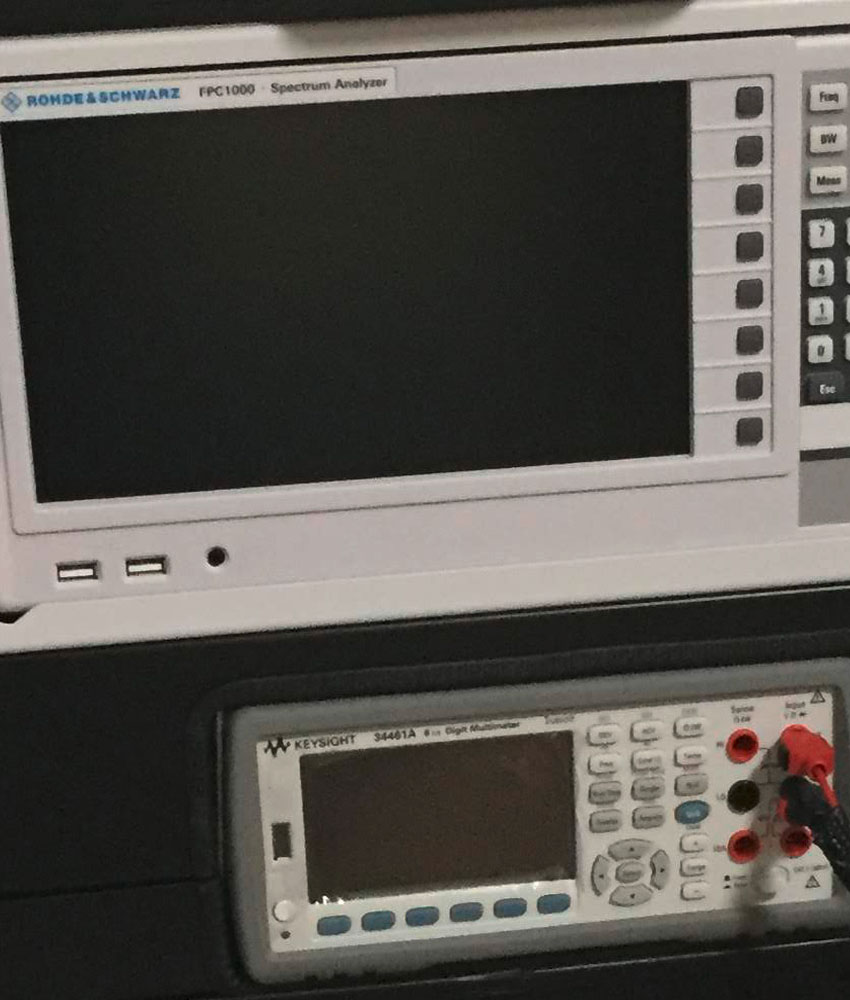

QMTInspect-100 technologies

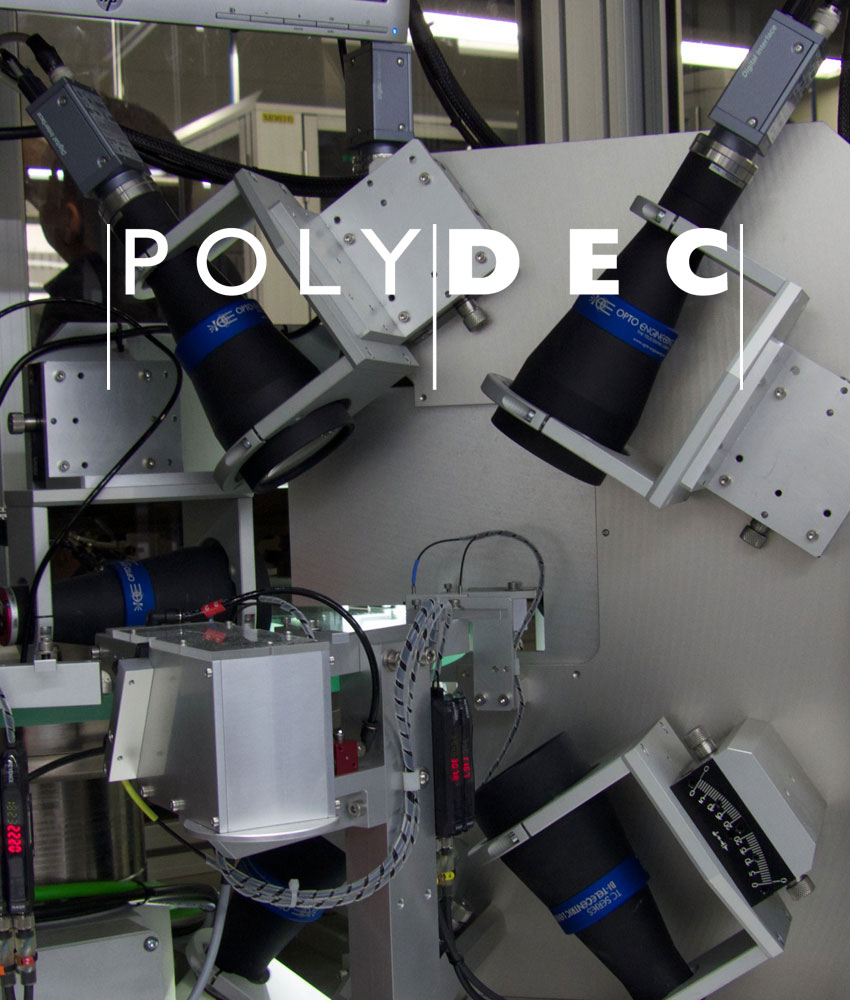

In order to guarantee the highest possible level of precision, the QMTProjector-300 integrates the most efficient optical technologies

This optical technology allows the removal of optical defects from

magnification, perspective errors and distortion.

3,318 x 2,712 pixels (9MPixels) or 10,000 x 7,096 pixels (71Mpixels)

the light is under the room in relation to the camera, this lighting only allows to visualize and measure the outline of the room but with very high precision.

the light is between the room and the camera, this lighting makes it possible to visualize and measure the surface of the room and all non-traversing geometries. There are several forms of episcopic lighting (annular, coaxial, dome, linear, spot, etc.) which each allow the observation of different characteristics.

Applications of the QMTInspect-100

The QMTInspect-100 offers very high rates and a high level of control accuracy. This machine is therefore ideal for high-speed control of technical parts

The possibility of using an Asyril charging station allows the control of fragile timepieces

QMTInspect-100 software

The software for high precision dimensional measurement with assisted programming

The control program is carried out using an intuitive interface comprising program models, standard control equations and functions which automatically detect and propose the characteristics of the part. The operator can thus select the controls and define the tolerances, the control program is thus created automatically. The possibility is also offered to add functions available in the QMTStore or to develop a personalized function through the Fit For You program.

The software for high precision dimensional measurement without any programming

Simply select the desired measurement function, place the part in the measurement area and read the measurement results on the screen. QMTMesure-Base includes a list of basic functions, options for advanced functions but also the possibility of adding personalized functions through the Fit For You program.

QMTMesure

Fit for you program (FFY)

Qualimatest products can be customized from both a hardware and software point of view. The first level of software customization is the addition of additional functions (available under QMTStore) or the development of a personalized function

On the basis of Qualimatest products, it is proposed to produce a product labeled in the name of our customers who can be private or marketed by themselves